Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

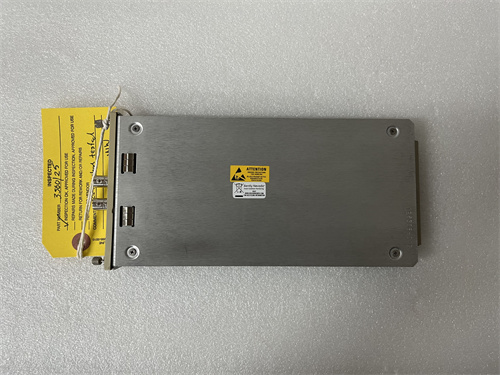

Bently Nevada 330881-28-04-090-03-02 PROXPAC XL Proximity Sensors

Manufacturer:Bently Nevada

Product Number:330881-28-04-090-03-02

Product Type:PROXPAC XL Proximity Sensors

Origin:USA

Dimensions:91.4 x 144.8 mm

Weight :1.44 kg

Views:4

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330881-28-04-090-03-02 PROXPAC XL Proximity Sensor is a high-precision industrial sensor designed to monitor machinery shaft vibration and position. It belongs to the PROXPAC XL series, known for its robust performance in harsh industrial environments. This sensor is commonly used in critical rotating equipment such as turbines, compressors, and motors, providing reliable measurements to ensure safe and efficient operation. The sensor integrates seamlessly with Bently Nevada monitoring systems, enabling real-time data acquisition for predictive maintenance and machinery protection.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330881-28-04-090-03-02 |

| Sensor Type | PROXPAC XL Proximity Sensor |

| Measurement Type | Shaft Vibration / Position |

| Frequency Response | 0.5 Hz – 20 kHz |

| Operating Temperature | -40°C to 120°C |

| Input Voltage | 18 – 36 VDC |

| Output Type | Differential / Single-ended |

| Accuracy | ±1 µm |

| Housing Material | Stainless Steel |

| Dimensions | 91.4 x 144.8 mm |

| Weight | 1.44 kg |

| Protection Rating | IP65 |

| Cable Type | Shielded Twisted Pair |

| Connector Type | 6-pin Industrial Connector |

Product Applications

-

Monitoring critical rotating equipment in power plants and industrial facilities.

-

Vibration and position sensing for turbines, compressors, generators, and motors.

-

Integration with Bently Nevada monitoring and protection systems for real-time diagnostics.

-

Predictive maintenance and condition monitoring of industrial machinery.

-

Detection of shaft displacement, misalignment, and imbalance.

Product Advantages

High Precision: Accurate shaft vibration and displacement measurements to detect early faults.

Robust Construction: Designed to withstand harsh industrial environments, including high temperature and vibration.

Seamless Integration: Fully compatible with Bently Nevada PROXPAC XL monitoring systems.

Real-Time Monitoring: Provides continuous measurement for predictive maintenance and reduced downtime.

Versatile Application: Suitable for a wide range of rotating machinery and industrial systems.

Easy Installation: Pre-calibrated and ready for rapid deployment in industrial settings.

FAQ

Q1: What types of machinery are compatible with this sensor?

A1: It is compatible with turbines, compressors, motors, and other rotating equipment monitored by Bently Nevada systems.

Q2: What is the maximum operating temperature?

A2: The sensor operates reliably up to 120°C.

Q3: How does the sensor interface with the PROXPAC XL system?

A3: It connects via a 6-pin industrial connector and transmits differential or single-ended signals to the monitoring system.

Q4: What is the typical response time of the sensor?

A4: The sensor provides near real-time response within milliseconds for high-speed shaft vibration detection.

Q5: Can this sensor detect shaft misalignment?

A5: Yes, the sensor measures shaft displacement and can identify misalignment or imbalance.

Q6: Does the sensor require recalibration after installation?

A6: It comes pre-calibrated; however, periodic system checks are recommended to maintain accuracy.

Q7: What kind of output signal does it provide?

A7: The sensor provides either differential or single-ended voltage outputs compatible with Bently Nevada monitoring units.

Q8: Is this sensor suitable for high-vibration environments?

A8: Yes, it is designed to operate reliably in environments with significant vibration and mechanical stress.

Q9: Can it detect both axial and radial shaft displacement?

A9: Yes, depending on the installation orientation, it can monitor both axial and radial movements.

Q10: What is the cable length limit for reliable operation?

A10: For optimal performance, cable lengths should typically not exceed 30 meters; longer runs may require signal conditioning.

Bently Nevada 330881-28-04-090-03-02 PROXPAC XL Proximity Sensors

Manufacturer:Bently Nevada

Product Number:330881-28-04-090-03-02

Product Type:PROXPAC XL Proximity Sensors

Origin:USA

Dimensions:91.4 x 144.8 mm

Weight :1.44 kg

Views:4

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330881-28-04-090-03-02 PROXPAC XL Proximity Sensor is a high-precision industrial sensor designed to monitor machinery shaft vibration and position. It belongs to the PROXPAC XL series, known for its robust performance in harsh industrial environments. This sensor is commonly used in critical rotating equipment such as turbines, compressors, and motors, providing reliable measurements to ensure safe and efficient operation. The sensor integrates seamlessly with Bently Nevada monitoring systems, enabling real-time data acquisition for predictive maintenance and machinery protection.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330881-28-04-090-03-02 |

| Sensor Type | PROXPAC XL Proximity Sensor |

| Measurement Type | Shaft Vibration / Position |

| Frequency Response | 0.5 Hz – 20 kHz |

| Operating Temperature | -40°C to 120°C |

| Input Voltage | 18 – 36 VDC |

| Output Type | Differential / Single-ended |

| Accuracy | ±1 µm |

| Housing Material | Stainless Steel |

| Dimensions | 91.4 x 144.8 mm |

| Weight | 1.44 kg |

| Protection Rating | IP65 |

| Cable Type | Shielded Twisted Pair |

| Connector Type | 6-pin Industrial Connector |

Product Applications

-

Monitoring critical rotating equipment in power plants and industrial facilities.

-

Vibration and position sensing for turbines, compressors, generators, and motors.

-

Integration with Bently Nevada monitoring and protection systems for real-time diagnostics.

-

Predictive maintenance and condition monitoring of industrial machinery.

-

Detection of shaft displacement, misalignment, and imbalance.

Product Advantages

High Precision: Accurate shaft vibration and displacement measurements to detect early faults.

Robust Construction: Designed to withstand harsh industrial environments, including high temperature and vibration.

Seamless Integration: Fully compatible with Bently Nevada PROXPAC XL monitoring systems.

Real-Time Monitoring: Provides continuous measurement for predictive maintenance and reduced downtime.

Versatile Application: Suitable for a wide range of rotating machinery and industrial systems.

Easy Installation: Pre-calibrated and ready for rapid deployment in industrial settings.

FAQ

Q1: What types of machinery are compatible with this sensor?

A1: It is compatible with turbines, compressors, motors, and other rotating equipment monitored by Bently Nevada systems.

Q2: What is the maximum operating temperature?

A2: The sensor operates reliably up to 120°C.

Q3: How does the sensor interface with the PROXPAC XL system?

A3: It connects via a 6-pin industrial connector and transmits differential or single-ended signals to the monitoring system.

Q4: What is the typical response time of the sensor?

A4: The sensor provides near real-time response within milliseconds for high-speed shaft vibration detection.

Q5: Can this sensor detect shaft misalignment?

A5: Yes, the sensor measures shaft displacement and can identify misalignment or imbalance.

Q6: Does the sensor require recalibration after installation?

A6: It comes pre-calibrated; however, periodic system checks are recommended to maintain accuracy.

Q7: What kind of output signal does it provide?

A7: The sensor provides either differential or single-ended voltage outputs compatible with Bently Nevada monitoring units.

Q8: Is this sensor suitable for high-vibration environments?

A8: Yes, it is designed to operate reliably in environments with significant vibration and mechanical stress.

Q9: Can it detect both axial and radial shaft displacement?

A9: Yes, depending on the installation orientation, it can monitor both axial and radial movements.

Q10: What is the cable length limit for reliable operation?

A10: For optimal performance, cable lengths should typically not exceed 30 meters; longer runs may require signal conditioning.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...