Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

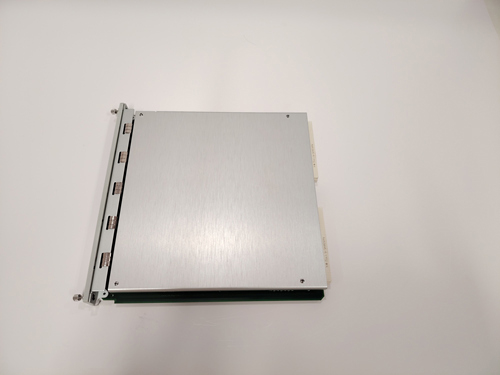

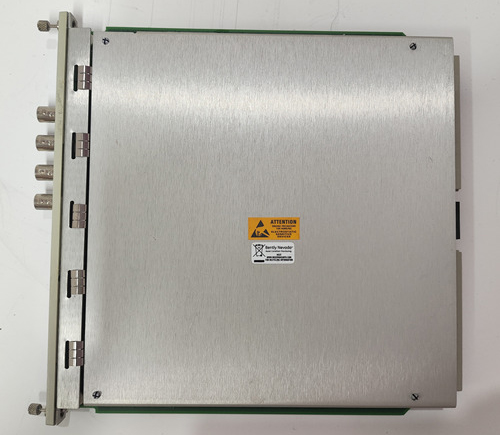

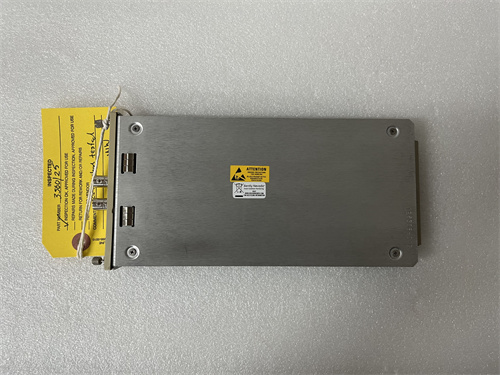

Bently Nevada 146031-01 Transient Data Interface Module

Module Number:146031-01

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

BENTLY 146031-01 is a transient data interface module mainly used to collect vibration, temperature, pressure, current and other data of rotating machinery (such as turbines, generators, compressors, etc.). These data are crucial for monitoring the performance and status of equipment.

Here are some detailed features about BENTLY 146031-01:

Transient data collection: This module is specifically designed for transient data collection and can capture and store data related to transient events and sudden changes. This is very useful for diagnosing mechanical problems and abnormal situations.

High sampling rate: BENTLY 146031-01 usually has a high sampling rate, which can capture and record transient events for subsequent analysis.

Data storage and transmission: This module may have a data storage function, which can record transient data and transmit it to monitoring systems or data analysis tools for processing.

Multi channel input: BENTLY 146031-01 may have multiple input channels that can simultaneously collect transient data from different locations or devices.

Industrial applications: In the industrial field, BENTLY 146031-01 is used for fault diagnosis, equipment status monitoring, and preventive maintenance. It is a very important equipment that can help factories and enterprises ensure the stability and reliability of the equipment.

In addition, BENTLY 146031-01 can also be compatible with certain specific systems (such as 3500/22M systems) as a 10Base-T/100Base-TX I/O module component. In these systems, it is responsible for combining the functions of the 3500/20 rack interface module with the data collection function of the communication processor, continuously capturing steady-state and transient waveform data, and transmitting it to the host software through an Ethernet link.

Bently Nevada 146031-01 Transient Data Interface Module

Module Number:146031-01

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

BENTLY 146031-01 is a transient data interface module mainly used to collect vibration, temperature, pressure, current and other data of rotating machinery (such as turbines, generators, compressors, etc.). These data are crucial for monitoring the performance and status of equipment.

Here are some detailed features about BENTLY 146031-01:

Transient data collection: This module is specifically designed for transient data collection and can capture and store data related to transient events and sudden changes. This is very useful for diagnosing mechanical problems and abnormal situations.

High sampling rate: BENTLY 146031-01 usually has a high sampling rate, which can capture and record transient events for subsequent analysis.

Data storage and transmission: This module may have a data storage function, which can record transient data and transmit it to monitoring systems or data analysis tools for processing.

Multi channel input: BENTLY 146031-01 may have multiple input channels that can simultaneously collect transient data from different locations or devices.

Industrial applications: In the industrial field, BENTLY 146031-01 is used for fault diagnosis, equipment status monitoring, and preventive maintenance. It is a very important equipment that can help factories and enterprises ensure the stability and reliability of the equipment.

In addition, BENTLY 146031-01 can also be compatible with certain specific systems (such as 3500/22M systems) as a 10Base-T/100Base-TX I/O module component. In these systems, it is responsible for combining the functions of the 3500/20 rack interface module with the data collection function of the communication processor, continuously capturing steady-state and transient waveform data, and transmitting it to the host software through an Ethernet link.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...