Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

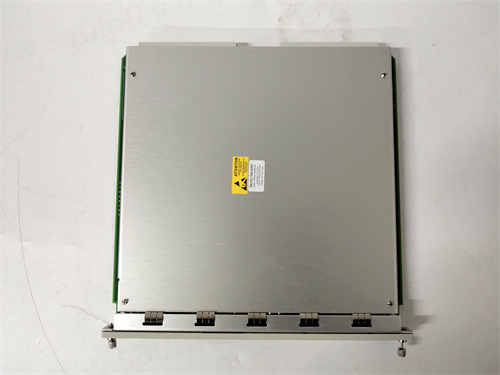

Bently Nevada 330703-000-050-10-02-05 3300 XL 11 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330703-000-050-10-02-05

Product Type:3300 XL 11 mm Proximity Probe

Origin:USA

Total Length:1m

Weight :0.07kg

Views:58

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330703-000-050-10-02-05 3300 XL 11 mm Proximity Probe is a highly reliable and precision-engineered sensor used in condition monitoring and vibration analysis of rotating machinery. This proximity probe is designed to measure displacement, vibration, and shaft position in industrial applications, ensuring optimal performance and reliability of machinery in critical environments. It plays a crucial role in identifying potential issues in rotating equipment such as motors, turbines, and compressors, preventing costly downtimes.

Technical Specifications

| Specification | Value |

|---|---|

| Total Length | 1 m |

| Weight | 0.07 kg |

| Operating Range | 0 to 25 mm |

| Probe Type | 3300 XL Series |

| Sensing Technology | Eddy Current |

| Material | Stainless Steel |

| Temperature Range | -40°C to 120°C |

| Maximum Vibration | 100 g |

| Voltage | 24 VDC |

| Output Signal | 4-20 mA |

| Protection Rating | IP65 |

Applications

Turbines: Continuous monitoring of turbine shafts to prevent misalignment or shaft damage.

Compressors: Ensuring accurate measurement of displacement in compressors to avoid operational failures.

Motors: Detecting early signs of vibration or misalignment in electric motors.

Pumps: Preventing issues such as cavitation or imbalance in pumping systems.

Gearboxes: Monitoring gear condition and ensuring proper operation.

Generators: Ensuring stability and reliability in generating units.

Advantages

High Accuracy: Provides precise measurements of displacement and vibration, enabling accurate condition monitoring.

Robust Design: Engineered for harsh industrial environments, resistant to dust, moisture, and vibration.

Extended Temperature Range: Operates effectively across a wide range of temperatures, from -40°C to 120°C.

Low Weight: Lightweight design for easy installation and minimal impact on machinery.

Durability: Stainless steel construction ensures long-lasting durability even in challenging environments.

Flexibility: Suitable for a wide range of rotating equipment including turbines, motors, and pumps.

FAQ

What is the maximum vibration level the probe can withstand?

The probe can withstand up to 100 g of vibration without compromising its functionality.

Can this probe be used in high-temperature environments?

Yes, it operates in temperatures ranging from -40°C to 120°C, making it suitable for high-temperature applications.

What type of output does the 3300 XL Proximity Probe provide?

The probe provides a 4-20 mA output signal for ease of integration with condition monitoring systems.

What is the maximum operating range of the proximity probe?

The probe has an operating range of up to 25 mm, allowing it to monitor a wide range of displacement values.

Is the Bently Nevada 3300 XL probe resistant to environmental factors?

Yes, the probe is rated IP65, meaning it is protected against dust and low-pressure water jets.

What materials are used in the construction of the probe?

The probe is made of durable stainless steel, which ensures resistance to corrosion and wear.

What is the purpose of the probe’s eddy current technology?

Eddy current technology allows for non-contact measurement of the displacement, ensuring high accuracy without physical wear.

How is the 3300 XL proximity probe typically mounted?

The probe is typically mounted on the shaft of rotating equipment and aligned for optimal performance in vibration and displacement measurements.

Can the proximity probe be used with other brands’ monitoring systems?

Yes, the 3300 XL probe can be integrated with most industrial condition monitoring systems that accept 4-20 mA signals.

What is the lifespan of the Bently Nevada 3300 XL proximity probe?

The probe has a long operational lifespan, typically lasting as long as the equipment it monitors, provided it is used within the specified environmental conditions.

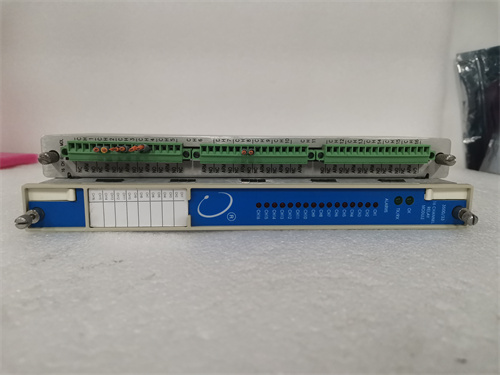

Bently Nevada 330703-000-050-10-02-05 3300 XL 11 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330703-000-050-10-02-05

Product Type:3300 XL 11 mm Proximity Probe

Origin:USA

Total Length:1m

Weight :0.07kg

Views:58

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330703-000-050-10-02-05 3300 XL 11 mm Proximity Probe is a highly reliable and precision-engineered sensor used in condition monitoring and vibration analysis of rotating machinery. This proximity probe is designed to measure displacement, vibration, and shaft position in industrial applications, ensuring optimal performance and reliability of machinery in critical environments. It plays a crucial role in identifying potential issues in rotating equipment such as motors, turbines, and compressors, preventing costly downtimes.

Technical Specifications

| Specification | Value |

|---|---|

| Total Length | 1 m |

| Weight | 0.07 kg |

| Operating Range | 0 to 25 mm |

| Probe Type | 3300 XL Series |

| Sensing Technology | Eddy Current |

| Material | Stainless Steel |

| Temperature Range | -40°C to 120°C |

| Maximum Vibration | 100 g |

| Voltage | 24 VDC |

| Output Signal | 4-20 mA |

| Protection Rating | IP65 |

Applications

Turbines: Continuous monitoring of turbine shafts to prevent misalignment or shaft damage.

Compressors: Ensuring accurate measurement of displacement in compressors to avoid operational failures.

Motors: Detecting early signs of vibration or misalignment in electric motors.

Pumps: Preventing issues such as cavitation or imbalance in pumping systems.

Gearboxes: Monitoring gear condition and ensuring proper operation.

Generators: Ensuring stability and reliability in generating units.

Advantages

High Accuracy: Provides precise measurements of displacement and vibration, enabling accurate condition monitoring.

Robust Design: Engineered for harsh industrial environments, resistant to dust, moisture, and vibration.

Extended Temperature Range: Operates effectively across a wide range of temperatures, from -40°C to 120°C.

Low Weight: Lightweight design for easy installation and minimal impact on machinery.

Durability: Stainless steel construction ensures long-lasting durability even in challenging environments.

Flexibility: Suitable for a wide range of rotating equipment including turbines, motors, and pumps.

FAQ

What is the maximum vibration level the probe can withstand?

The probe can withstand up to 100 g of vibration without compromising its functionality.

Can this probe be used in high-temperature environments?

Yes, it operates in temperatures ranging from -40°C to 120°C, making it suitable for high-temperature applications.

What type of output does the 3300 XL Proximity Probe provide?

The probe provides a 4-20 mA output signal for ease of integration with condition monitoring systems.

What is the maximum operating range of the proximity probe?

The probe has an operating range of up to 25 mm, allowing it to monitor a wide range of displacement values.

Is the Bently Nevada 3300 XL probe resistant to environmental factors?

Yes, the probe is rated IP65, meaning it is protected against dust and low-pressure water jets.

What materials are used in the construction of the probe?

The probe is made of durable stainless steel, which ensures resistance to corrosion and wear.

What is the purpose of the probe’s eddy current technology?

Eddy current technology allows for non-contact measurement of the displacement, ensuring high accuracy without physical wear.

How is the 3300 XL proximity probe typically mounted?

The probe is typically mounted on the shaft of rotating equipment and aligned for optimal performance in vibration and displacement measurements.

Can the proximity probe be used with other brands’ monitoring systems?

Yes, the 3300 XL probe can be integrated with most industrial condition monitoring systems that accept 4-20 mA signals.

What is the lifespan of the Bently Nevada 3300 XL proximity probe?

The probe has a long operational lifespan, typically lasting as long as the equipment it monitors, provided it is used within the specified environmental conditions.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...