Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

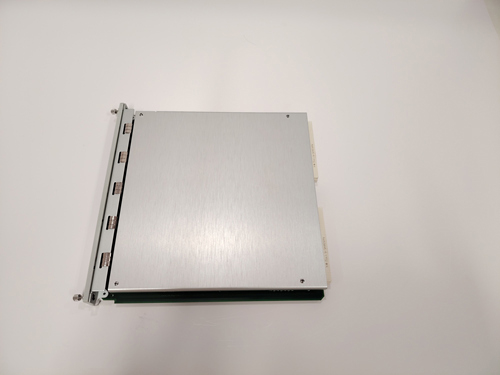

Bently Nevada 990-04-90-01-05 990 Vibration Transmitter

Manufacturer:Bently Nevada

Product Number:990-04-90-01-05

Product Type:990 Vibration Transmitter

Origin:USA

Dimensions:100.1 x 73.9 x 53.3mm

Weight:0.43kg

Views:21

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 990-04-90-01-05 990 Vibration Transmitter is a compact, high-reliability device designed to monitor vibration in rotating machinery. It converts signals from 3300 XL Proximity Probes into a standard 4–20 mA output, enabling integration with DCS, PLC, or SCADA systems for condition monitoring and machinery protection.

Key Features

-

Compatible with Bently Nevada 3300 XL Proximity Probes

-

Provides 4–20 mA output proportional to vibration amplitude

-

Monitors radial vibration, shaft position, and thrust position

-

Compact, durable housing for harsh industrial conditions

-

DIN-rail or panel mounting options

-

Meets API 670 machinery protection standards

-

Simple installation and easy integration with existing systems

Technical Specifications

| Item | Specification |

|---|---|

| Model Number | 990-04-90-01-05 |

| Series | Bently Nevada 990 Vibration Transmitter |

| Input | Bently Nevada 3300 XL Proximity Probe system |

| Output Signal | 4–20 mA proportional to vibration |

| Measurement Type | Radial vibration, shaft position, or thrust position |

| Power Supply | 18–36 VDC |

| Frequency Response | DC to 10 kHz |

| Sensitivity | Configured per API 670 standard |

| Operating Temperature | -35 °C to +85 °C |

| Storage Temperature | -51 °C to +100 °C |

| Dimensions | 100.1 x 73.9 x 53.3 mm |

| Weight | 0.43 kg |

| Mounting | DIN-rail or panel-mounted |

| Compliance | API 670, CE, CSA, ATEX (varies by model) |

Industry Applications

-

Oil & gas machinery protection

-

Petrochemical process machinery monitoring

-

Manufacturing equipment vibration monitoring

-

Marine & offshore rotating machinery

-

Condition-based maintenance programs

-

Industrial automation systems

Advantages

-

Reliable vibration and shaft position measurement

-

Compact, cost-effective solution for machinery protection

-

Meets API 670 compliance standards

-

Compatible with existing 3300 XL Proximity Probes

-

Reduces downtime and maintenance costs

Frequently Asked Questions (FAQ)

Q1: What is the primary function of this transmitter?

It measures machinery vibration and outputs a 4–20 mA signal for monitoring and protection.

Q2: Which probes are compatible?

Bently Nevada 3300 XL Proximity Probes.

Q3: Does it comply with API 670 standards?

Yes, it meets API 670 machinery protection requirements.

Q4: Can it be connected to a DCS or PLC?

Yes, the 4–20 mA output allows direct integration.

Q5: What measurements can it perform?

Radial vibration, shaft position, and thrust position.

Q6: What is the operating temperature range?

-35 °C to +85 °C.

Q7: How is it mounted?

DIN-rail or panel-mounted.

Q8: Is it suitable for harsh environments?

Yes, it is designed for industrial conditions and some models meet CSA/ATEX standards.

Q9: What is the weight of the transmitter?

Approximately 0.43 kg .

Q10: Why choose this transmitter over a rack-based system?

It offers a compact, cost-effective solution while providing reliable vibration monitoring.

Bently Nevada 990-04-90-01-05 990 Vibration Transmitter

Manufacturer:Bently Nevada

Product Number:990-04-90-01-05

Product Type:990 Vibration Transmitter

Origin:USA

Dimensions:100.1 x 73.9 x 53.3mm

Weight:0.43kg

Views:21

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 990-04-90-01-05 990 Vibration Transmitter is a compact, high-reliability device designed to monitor vibration in rotating machinery. It converts signals from 3300 XL Proximity Probes into a standard 4–20 mA output, enabling integration with DCS, PLC, or SCADA systems for condition monitoring and machinery protection.

Key Features

-

Compatible with Bently Nevada 3300 XL Proximity Probes

-

Provides 4–20 mA output proportional to vibration amplitude

-

Monitors radial vibration, shaft position, and thrust position

-

Compact, durable housing for harsh industrial conditions

-

DIN-rail or panel mounting options

-

Meets API 670 machinery protection standards

-

Simple installation and easy integration with existing systems

Technical Specifications

| Item | Specification |

|---|---|

| Model Number | 990-04-90-01-05 |

| Series | Bently Nevada 990 Vibration Transmitter |

| Input | Bently Nevada 3300 XL Proximity Probe system |

| Output Signal | 4–20 mA proportional to vibration |

| Measurement Type | Radial vibration, shaft position, or thrust position |

| Power Supply | 18–36 VDC |

| Frequency Response | DC to 10 kHz |

| Sensitivity | Configured per API 670 standard |

| Operating Temperature | -35 °C to +85 °C |

| Storage Temperature | -51 °C to +100 °C |

| Dimensions | 100.1 x 73.9 x 53.3 mm |

| Weight | 0.43 kg |

| Mounting | DIN-rail or panel-mounted |

| Compliance | API 670, CE, CSA, ATEX (varies by model) |

Industry Applications

-

Oil & gas machinery protection

-

Petrochemical process machinery monitoring

-

Manufacturing equipment vibration monitoring

-

Marine & offshore rotating machinery

-

Condition-based maintenance programs

-

Industrial automation systems

Advantages

-

Reliable vibration and shaft position measurement

-

Compact, cost-effective solution for machinery protection

-

Meets API 670 compliance standards

-

Compatible with existing 3300 XL Proximity Probes

-

Reduces downtime and maintenance costs

Frequently Asked Questions (FAQ)

Q1: What is the primary function of this transmitter?

It measures machinery vibration and outputs a 4–20 mA signal for monitoring and protection.

Q2: Which probes are compatible?

Bently Nevada 3300 XL Proximity Probes.

Q3: Does it comply with API 670 standards?

Yes, it meets API 670 machinery protection requirements.

Q4: Can it be connected to a DCS or PLC?

Yes, the 4–20 mA output allows direct integration.

Q5: What measurements can it perform?

Radial vibration, shaft position, and thrust position.

Q6: What is the operating temperature range?

-35 °C to +85 °C.

Q7: How is it mounted?

DIN-rail or panel-mounted.

Q8: Is it suitable for harsh environments?

Yes, it is designed for industrial conditions and some models meet CSA/ATEX standards.

Q9: What is the weight of the transmitter?

Approximately 0.43 kg .

Q10: Why choose this transmitter over a rack-based system?

It offers a compact, cost-effective solution while providing reliable vibration monitoring.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...