Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

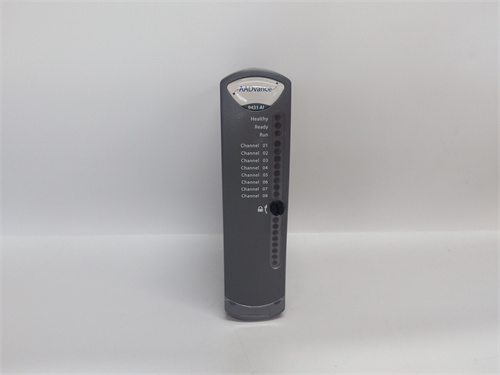

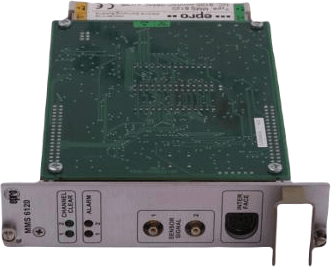

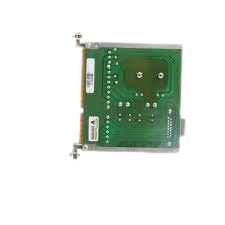

Emerson A6410 Valve & Case Expansion Monitor

Module Number:A6410

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

The Emerson A6410 module is a valve and housing expansion monitor designed specifically for critical rotating machinery in factories, with high reliability and versatility. The following is a detailed introduction to the Emerson A6410 module:

Overview

The Emerson A6410 module, as part of the AMS 6500 Mechanical Health Monitor, is designed to provide comprehensive monitoring of critical rotating machinery such as steam, gas, compressors, and water turbines within the factory. By being used in conjunction with other AMS 6500 monitors, the A6410 module can build a complete API 670 mechanical protection monitoring system, ensuring the safety and stability of mechanical operation.

Main functions

Valve position monitoring: The A6410 module can accurately measure the position of the main steam inlet valve stem, usually displayed as a percentage opening, providing the operator with an indication of the current load on the turbine.

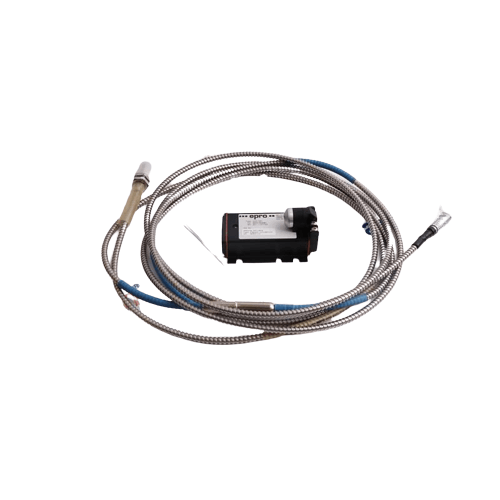

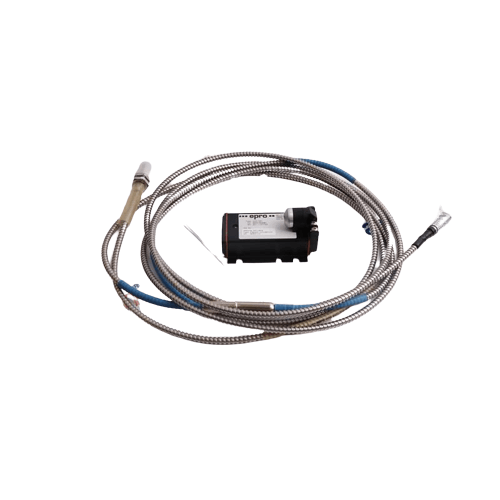

Shell Expansion Monitoring: By installing inductive displacement sensors (such as the 9350 series), the A6410 module can monitor the expansion of the turbine shell, ensuring the appropriate expansion rate of the shell during start-up and operation, and preventing mechanical failures caused by uneven expansion.

Emerson A6410 Valve & Case Expansion Monitor

Module Number:A6410

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

The Emerson A6410 module is a valve and housing expansion monitor designed specifically for critical rotating machinery in factories, with high reliability and versatility. The following is a detailed introduction to the Emerson A6410 module:

Overview

The Emerson A6410 module, as part of the AMS 6500 Mechanical Health Monitor, is designed to provide comprehensive monitoring of critical rotating machinery such as steam, gas, compressors, and water turbines within the factory. By being used in conjunction with other AMS 6500 monitors, the A6410 module can build a complete API 670 mechanical protection monitoring system, ensuring the safety and stability of mechanical operation.

Main functions

Valve position monitoring: The A6410 module can accurately measure the position of the main steam inlet valve stem, usually displayed as a percentage opening, providing the operator with an indication of the current load on the turbine.

Shell Expansion Monitoring: By installing inductive displacement sensors (such as the 9350 series), the A6410 module can monitor the expansion of the turbine shell, ensuring the appropriate expansion rate of the shell during start-up and operation, and preventing mechanical failures caused by uneven expansion.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...