Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

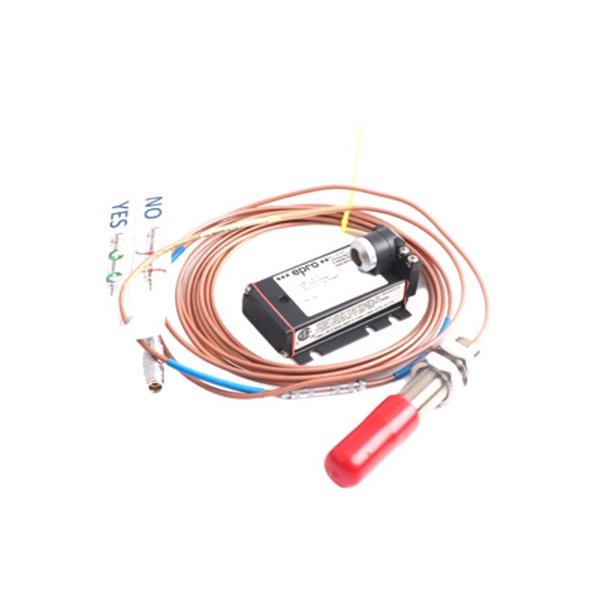

Epro PR6424/117-021 16mm Eddy Current Sensor

Manufacturer:Epro

Product Number:PR6424/117-021

Product Type:16mm Eddy Current Sensor

Origin:Germany

Sensor Head Diameter:16 mm

Weight:0.2 kg

Views:74

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Epro PR6424/117-021 is a non-contact eddy current displacement sensor designed for precise vibration and position monitoring in industrial rotating machinery. It is widely used in condition monitoring systems, especially in harsh environments such as turbines, compressors, and motors.

Technical Specifications

| Parameter | Value |

|---|---|

| Sensor Type | Eddy Current Displacement Sensor |

| Model Number | PR6424/117-021 |

| Measuring Range | 2 mm (Typical) |

| Sensitivity | 7.87 mV/μm (Standard) |

| Frequency Range | DC to 10 kHz |

| Temperature Range | -35°C to +180°C |

| Linearity | ≤ ±1% of Full Scale |

| Sensor Tip Diameter | 16 mm |

| Probe Material | Stainless Steel |

| Weight | Approx. 0.2 kg |

| Mounting Thread | M14x1.5 |

| Cable Type | Integrated Coaxial |

| Typical Applications | Turbines, Compressors, Pumps |

Applications

-

Vibration monitoring of turbines, compressors, and large motors

-

Axial and radial shaft displacement detection

-

Bearing and rotor dynamic analysis

-

Integrated in machine protection systems

Product Advantages

-

High precision in harsh industrial conditions

-

Wide temperature range for demanding applications

-

Rugged stainless steel housing ensures durability

-

Compatible with PR6423 and PR6422 series proximity systems

-

Easy integration into existing monitoring systems

-

Reliable signal quality with integrated coaxial cable

FAQ

Q1: What is the typical measuring range of PR6424/117-021?

A1: It typically measures up to 2 mm of displacement.

Q2: Can this sensor operate in high-temperature environments?

A2: Yes, it supports operation from -35°C up to +180°C.

Q3: Is the sensor suitable for turbine monitoring?

A3: Yes, it is widely used in turbines and similar rotating machinery.

Q4: What is the sensor’s output sensitivity?

A4: The output sensitivity is approximately 7.87 mV/μm.

Q5: What materials are used in the probe construction?

A5: The probe housing is made of stainless steel for corrosion resistance.

Q6: Is it compatible with Epro signal converters?

A6: Yes, it is compatible with PR6423/PR6422 converter systems.

Q7: How is the sensor mounted?

A7: It is mounted using an M14x1.5 threaded connection.

Q8: What type of cable is integrated?

A8: It features an integrated coaxial cable for signal transmission.

Q9: Can this sensor detect both radial and axial displacement?

A9: Yes, it is designed for both types of displacement detection.

Q10: What is the weight of the sensor?

A10: The sensor weighs approximately 0.2 kg.

Epro PR6424/117-021 16mm Eddy Current Sensor

Manufacturer:Epro

Product Number:PR6424/117-021

Product Type:16mm Eddy Current Sensor

Origin:Germany

Sensor Head Diameter:16 mm

Weight:0.2 kg

Views:74

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Epro PR6424/117-021 is a non-contact eddy current displacement sensor designed for precise vibration and position monitoring in industrial rotating machinery. It is widely used in condition monitoring systems, especially in harsh environments such as turbines, compressors, and motors.

Technical Specifications

| Parameter | Value |

|---|---|

| Sensor Type | Eddy Current Displacement Sensor |

| Model Number | PR6424/117-021 |

| Measuring Range | 2 mm (Typical) |

| Sensitivity | 7.87 mV/μm (Standard) |

| Frequency Range | DC to 10 kHz |

| Temperature Range | -35°C to +180°C |

| Linearity | ≤ ±1% of Full Scale |

| Sensor Tip Diameter | 16 mm |

| Probe Material | Stainless Steel |

| Weight | Approx. 0.2 kg |

| Mounting Thread | M14x1.5 |

| Cable Type | Integrated Coaxial |

| Typical Applications | Turbines, Compressors, Pumps |

Applications

-

Vibration monitoring of turbines, compressors, and large motors

-

Axial and radial shaft displacement detection

-

Bearing and rotor dynamic analysis

-

Integrated in machine protection systems

Product Advantages

-

High precision in harsh industrial conditions

-

Wide temperature range for demanding applications

-

Rugged stainless steel housing ensures durability

-

Compatible with PR6423 and PR6422 series proximity systems

-

Easy integration into existing monitoring systems

-

Reliable signal quality with integrated coaxial cable

FAQ

Q1: What is the typical measuring range of PR6424/117-021?

A1: It typically measures up to 2 mm of displacement.

Q2: Can this sensor operate in high-temperature environments?

A2: Yes, it supports operation from -35°C up to +180°C.

Q3: Is the sensor suitable for turbine monitoring?

A3: Yes, it is widely used in turbines and similar rotating machinery.

Q4: What is the sensor’s output sensitivity?

A4: The output sensitivity is approximately 7.87 mV/μm.

Q5: What materials are used in the probe construction?

A5: The probe housing is made of stainless steel for corrosion resistance.

Q6: Is it compatible with Epro signal converters?

A6: Yes, it is compatible with PR6423/PR6422 converter systems.

Q7: How is the sensor mounted?

A7: It is mounted using an M14x1.5 threaded connection.

Q8: What type of cable is integrated?

A8: It features an integrated coaxial cable for signal transmission.

Q9: Can this sensor detect both radial and axial displacement?

A9: Yes, it is designed for both types of displacement detection.

Q10: What is the weight of the sensor?

A10: The sensor weighs approximately 0.2 kg.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...