Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

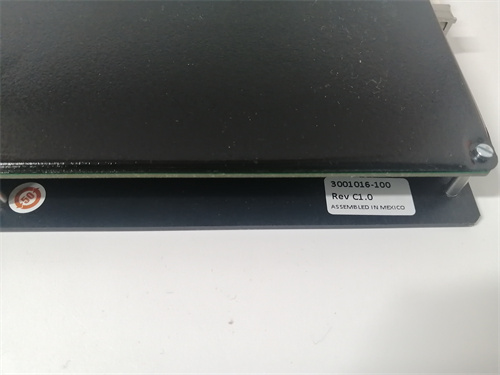

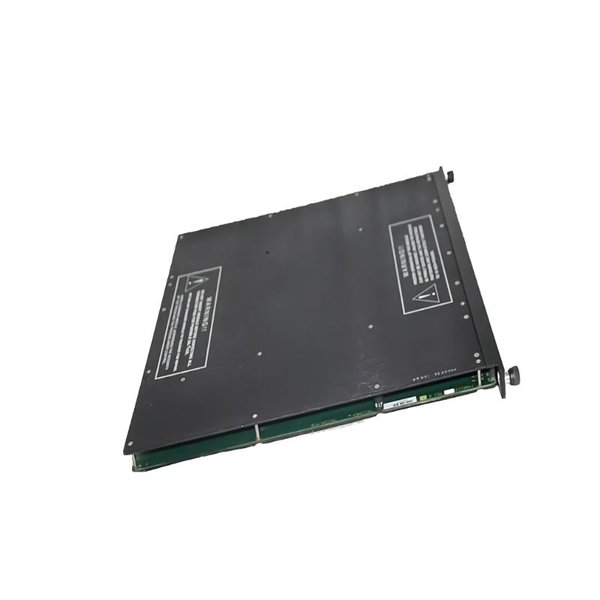

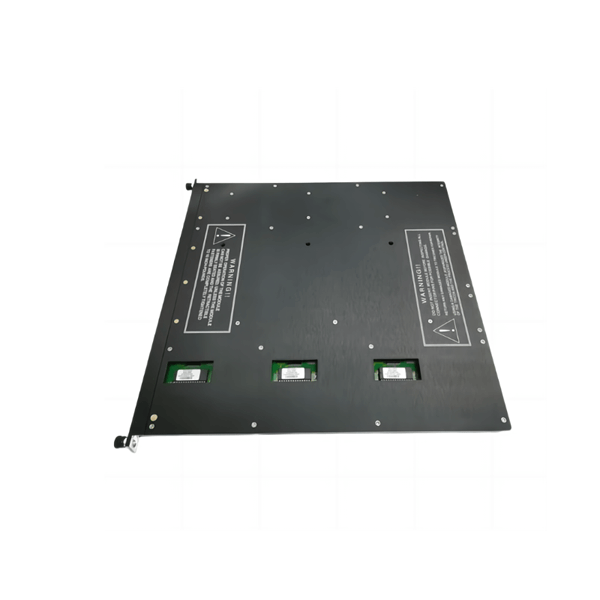

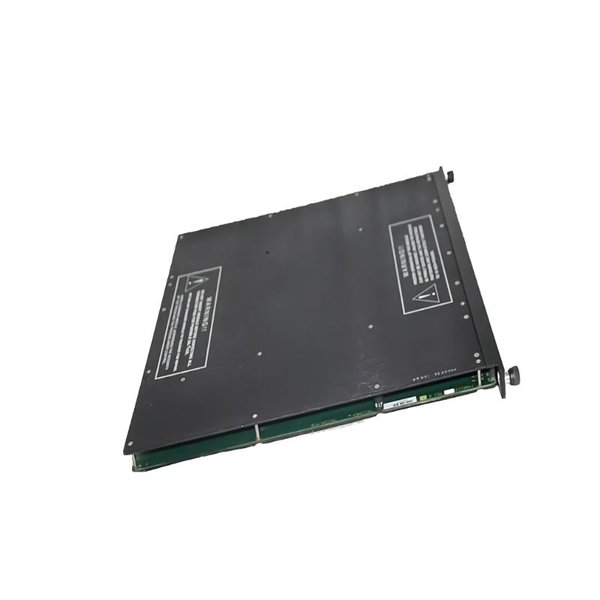

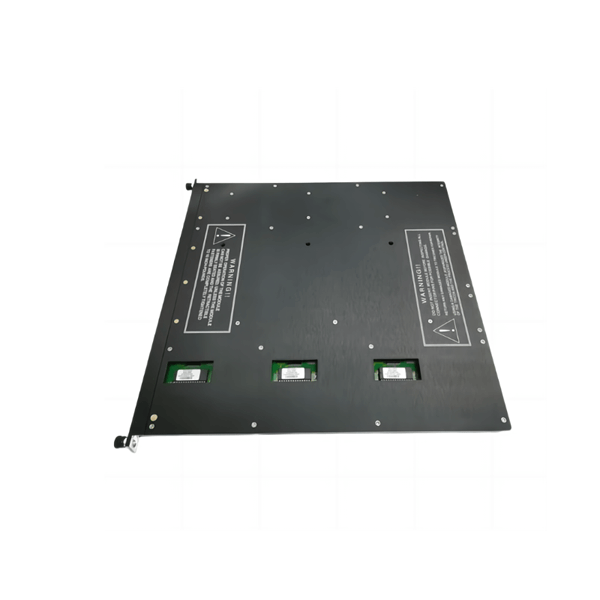

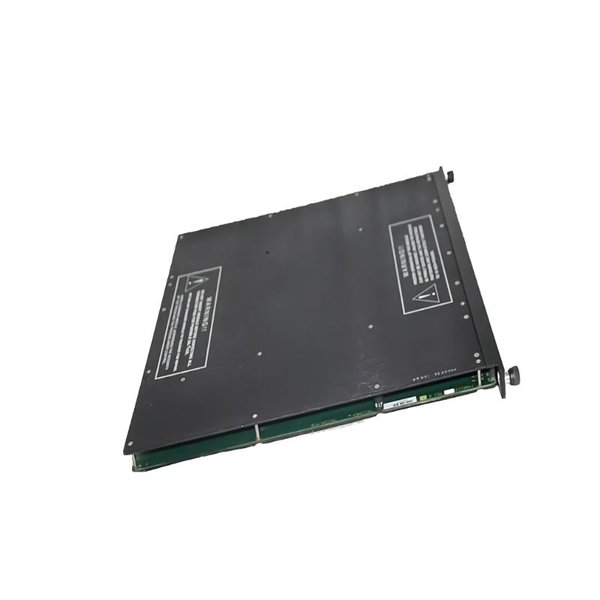

Triconex 4200 Remote Extender Module

Manufacturer:Triconex

Product Number:4200

Product Type:Remote Extender Module

Origin:USA

Dimensions:326 x 260 x 50 mm

Weight:5.45 kg

Views:108

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

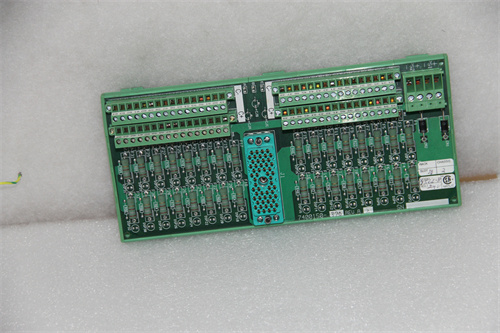

The Triconex 4200 Remote Extender Module is a critical component of Schneider Electric’s Triconex family of safety and control systems. Designed to support distributed or remote I/O architectures, the 4200 module allows users to extend the reach of the Triconex safety system across wider geographical or plant layouts without compromising on reliability, speed, or safety integrity.

Operating as a high-speed communication bridge between the main chassis and remote I/O racks, the Triconex 4200 ensures deterministic performance even in harsh industrial environments. This module plays a central role in large-scale safety instrumented systems (SIS), especially where physical separation between control and field equipment is required due to safety regulations or hazardous area classifications.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | Triconex 4200 |

| Description | Remote Extender Module for remote I/O expansion |

| Communication Interface | Proprietary Tricon high-speed serial link |

| Supported Chassis | Tricon V9/V10 Main Chassis, Remote I/O Base |

| Number of Supported Remotes | Up to 8 Remote I/O Base configurations |

| Power Supply | 5 VDC, supplied from chassis backplane |

| Operating Temperature Range | -20°C to +70°C |

| Storage Temperature Range | -40°C to +85°C |

| Relative Humidity | 5% to 95%, non-condensing |

| Electromagnetic Compatibility | IEC 61000-4, EN 50081, EN 50082 |

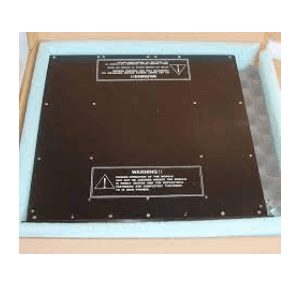

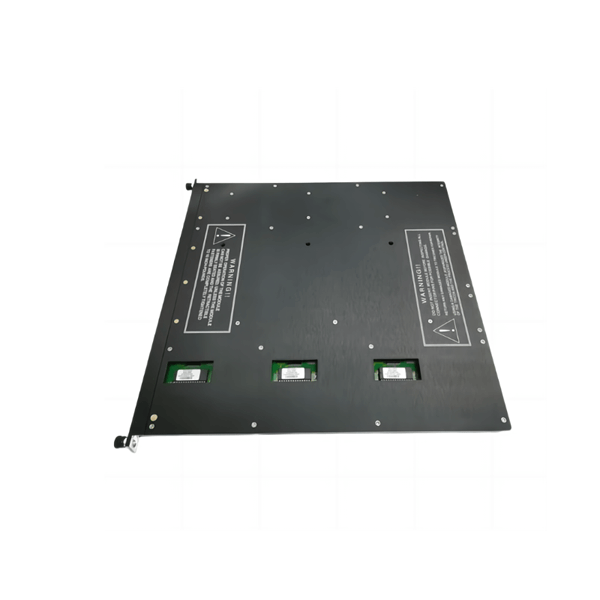

| Dimensions (H x W x D) | 326 x 260 x 50 mm |

| Weight | 5.45 kg |

| Mounting Type | DIN rail or backplane-mounted in Tricon chassis |

| Compliance | SIL 3 Certified (IEC 61508), TUV-approved |

Applications

The Triconex 4200 Remote Extender Module is ideal for deployment in:

Oil & Gas processing facilities

For geographically dispersed gas compression stations and wellheads requiring remote control and monitoring.

Petrochemical and refining plants

Used to safely interface distributed safety systems across large tank farms and refining zones.

Power generation plants

Enables turbine safety and boiler protection systems to span multiple floors or zones without signal degradation.

Pharmaceutical manufacturing

When equipment must be isolated for safety but needs centralized safety system integration.

Water & wastewater treatment

Ensures safe, synchronized operations between distant pumping stations and treatment tanks.

Advantages

Extended Reach with Integrity

Enables safe, high-speed remote connections over long distances while maintaining system reliability and determinism.

Plug-and-Play Compatibility

Seamless integration into the Tricon safety system without requiring major reconfiguration.

Certified Safety

Fully certified to SIL 3 standards for safety-critical applications, ensuring compliance with global safety regulations.

High Availability

Designed for continuous operation with redundant communication paths to avoid single points of failure.

Rugged Design

Engineered to operate reliably in industrial environments with wide temperature and humidity ranges.

Scalability

Supports the connection of multiple remote I/O chassis, making it ideal for expanding facilities.

FAQ

What is the function of the Triconex 4200 Remote Extender Module?

It extends the communication between the Tricon main processor and remote I/O chassis over long distances.

Is the 4200 module compatible with all Triconex systems?

It is primarily compatible with Tricon V9 and V10 systems and requires compatible chassis and I/O bases.

What is the maximum number of remote chassis that can be connected using the 4200?

Up to 8 remote chassis can be configured depending on system architecture.

Does the 4200 module require external power supply?

No, it draws power directly from the Tricon backplane.

Is the Triconex 4200 suitable for outdoor use?

While it has industrial-grade temperature and humidity tolerance, it should be enclosed per typical industrial panel standards.

Can the 4200 module be hot-swapped?

No, it must be inserted or removed with system power off to avoid faults or damage.

Does the module provide redundancy options?

Yes, dual modules can be used for redundant communication links to remote I/O bases.

What type of communication cable is used with the 4200 module?

Triconex-specific high-integrity communication cables are required for remote links.

How is diagnostics handled in case of a link failure?

The module supports system-level diagnostics and can report faults via Tricon system alarms.

Is the Triconex 4200 module certified for functional safety?

Yes, it is SIL 3 certified per IEC 61508 and is TUV-approved.

Triconex 4200 Remote Extender Module

Manufacturer:Triconex

Product Number:4200

Product Type:Remote Extender Module

Origin:USA

Dimensions:326 x 260 x 50 mm

Weight:5.45 kg

Views:108

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Triconex 4200 Remote Extender Module is a critical component of Schneider Electric’s Triconex family of safety and control systems. Designed to support distributed or remote I/O architectures, the 4200 module allows users to extend the reach of the Triconex safety system across wider geographical or plant layouts without compromising on reliability, speed, or safety integrity.

Operating as a high-speed communication bridge between the main chassis and remote I/O racks, the Triconex 4200 ensures deterministic performance even in harsh industrial environments. This module plays a central role in large-scale safety instrumented systems (SIS), especially where physical separation between control and field equipment is required due to safety regulations or hazardous area classifications.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | Triconex 4200 |

| Description | Remote Extender Module for remote I/O expansion |

| Communication Interface | Proprietary Tricon high-speed serial link |

| Supported Chassis | Tricon V9/V10 Main Chassis, Remote I/O Base |

| Number of Supported Remotes | Up to 8 Remote I/O Base configurations |

| Power Supply | 5 VDC, supplied from chassis backplane |

| Operating Temperature Range | -20°C to +70°C |

| Storage Temperature Range | -40°C to +85°C |

| Relative Humidity | 5% to 95%, non-condensing |

| Electromagnetic Compatibility | IEC 61000-4, EN 50081, EN 50082 |

| Dimensions (H x W x D) | 326 x 260 x 50 mm |

| Weight | 5.45 kg |

| Mounting Type | DIN rail or backplane-mounted in Tricon chassis |

| Compliance | SIL 3 Certified (IEC 61508), TUV-approved |

Applications

The Triconex 4200 Remote Extender Module is ideal for deployment in:

Oil & Gas processing facilities

For geographically dispersed gas compression stations and wellheads requiring remote control and monitoring.

Petrochemical and refining plants

Used to safely interface distributed safety systems across large tank farms and refining zones.

Power generation plants

Enables turbine safety and boiler protection systems to span multiple floors or zones without signal degradation.

Pharmaceutical manufacturing

When equipment must be isolated for safety but needs centralized safety system integration.

Water & wastewater treatment

Ensures safe, synchronized operations between distant pumping stations and treatment tanks.

Advantages

Extended Reach with Integrity

Enables safe, high-speed remote connections over long distances while maintaining system reliability and determinism.

Plug-and-Play Compatibility

Seamless integration into the Tricon safety system without requiring major reconfiguration.

Certified Safety

Fully certified to SIL 3 standards for safety-critical applications, ensuring compliance with global safety regulations.

High Availability

Designed for continuous operation with redundant communication paths to avoid single points of failure.

Rugged Design

Engineered to operate reliably in industrial environments with wide temperature and humidity ranges.

Scalability

Supports the connection of multiple remote I/O chassis, making it ideal for expanding facilities.

FAQ

What is the function of the Triconex 4200 Remote Extender Module?

It extends the communication between the Tricon main processor and remote I/O chassis over long distances.

Is the 4200 module compatible with all Triconex systems?

It is primarily compatible with Tricon V9 and V10 systems and requires compatible chassis and I/O bases.

What is the maximum number of remote chassis that can be connected using the 4200?

Up to 8 remote chassis can be configured depending on system architecture.

Does the 4200 module require external power supply?

No, it draws power directly from the Tricon backplane.

Is the Triconex 4200 suitable for outdoor use?

While it has industrial-grade temperature and humidity tolerance, it should be enclosed per typical industrial panel standards.

Can the 4200 module be hot-swapped?

No, it must be inserted or removed with system power off to avoid faults or damage.

Does the module provide redundancy options?

Yes, dual modules can be used for redundant communication links to remote I/O bases.

What type of communication cable is used with the 4200 module?

Triconex-specific high-integrity communication cables are required for remote links.

How is diagnostics handled in case of a link failure?

The module supports system-level diagnostics and can report faults via Tricon system alarms.

Is the Triconex 4200 module certified for functional safety?

Yes, it is SIL 3 certified per IEC 61508 and is TUV-approved.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...