Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

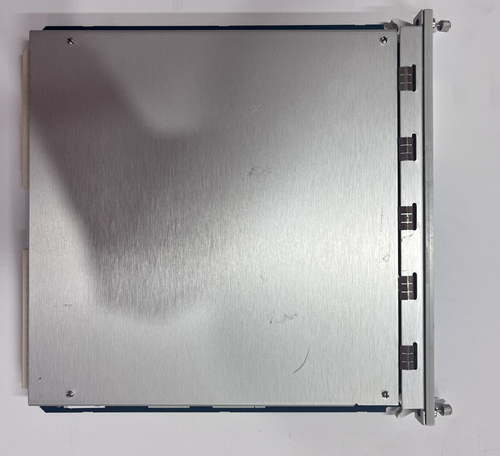

Bently Nevada 3300/65-13-01-00-00-00-00 Specialized Device

Brand:Bently Nevada

Model Number:3300/65-13-01-00-00-00-00

Type:Specialized Device

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:155 x 136 x 119 mm

Weight:280g

Price:USD87

Certificate:CE

Warranty:1 years

Product Description

Bently Nevada 3300/65-13-01-00-00-00-00 is a specialized device designed to monitor the radial vibration of rotating machinery. This equipment is crucial in industrial settings for assessing the health and performance of large rotating machines such as turbines, pumps, and compressors.

Key Features and Functions

- Dual Probe Monitoring: The device uses two probes to measure vibration in two perpendicular axes. This setup provides a comprehensive assessment of the machine’s vibrational behavior.

- High-Precision Measurement: It delivers accurate measurements of vibration amplitude, frequency, and phase. This precision enables early detection of potential issues.

- Robust Design: Built to endure harsh industrial environments, the monitor is designed for continuous operation and reliability.

- Data Acquisition: It collects and stores vibration data over time, facilitating trend analysis and predictive maintenance.

- Integration Capabilities: The monitor integrates with larger monitoring systems. This integration allows for condition-based monitoring and control.

Technical Specifications

While exact specifications depend on the revision or configuration, general parameters include:

- Measurement Range: Covers a wide range of vibration amplitudes, from low-level vibrations to high-severity faults.

- Frequency Range: Captures a broad spectrum of frequencies, including those associated with common mechanical faults.

- Sensitivity: High sensitivity enables early fault detection.

- Accuracy: Designed to meet stringent accuracy standards for reliable diagnosis.

- Environmental Rating: Rated for industrial environments, offering protection against dust, moisture, and temperature extremes.

- Communication: Supports various communication protocols, such as Modbus and Ethernet, for integration into control systems.

Applications

- Predictive Maintenance: Detect faults early to prevent unplanned downtime and costly repairs.

- Condition Monitoring: Continuously monitor vibration levels for valuable insights into equipment health.

- Fault Diagnosis: Analyze vibration data to identify the root cause of mechanical problems.

- Process Optimization: Use vibration monitoring to enhance equipment performance and efficiency.

Bently Nevada 3300/65-13-01-00-00-00-00 Specialized Device

Brand:Bently Nevada

Model Number:3300/65-13-01-00-00-00-00

Type:Specialized Device

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:155 x 136 x 119 mm

Weight:280g

Price:USD87

Certificate:CE

Warranty:1 years

Product Description

Bently Nevada 3300/65-13-01-00-00-00-00 is a specialized device designed to monitor the radial vibration of rotating machinery. This equipment is crucial in industrial settings for assessing the health and performance of large rotating machines such as turbines, pumps, and compressors.

Key Features and Functions

- Dual Probe Monitoring: The device uses two probes to measure vibration in two perpendicular axes. This setup provides a comprehensive assessment of the machine’s vibrational behavior.

- High-Precision Measurement: It delivers accurate measurements of vibration amplitude, frequency, and phase. This precision enables early detection of potential issues.

- Robust Design: Built to endure harsh industrial environments, the monitor is designed for continuous operation and reliability.

- Data Acquisition: It collects and stores vibration data over time, facilitating trend analysis and predictive maintenance.

- Integration Capabilities: The monitor integrates with larger monitoring systems. This integration allows for condition-based monitoring and control.

Technical Specifications

While exact specifications depend on the revision or configuration, general parameters include:

- Measurement Range: Covers a wide range of vibration amplitudes, from low-level vibrations to high-severity faults.

- Frequency Range: Captures a broad spectrum of frequencies, including those associated with common mechanical faults.

- Sensitivity: High sensitivity enables early fault detection.

- Accuracy: Designed to meet stringent accuracy standards for reliable diagnosis.

- Environmental Rating: Rated for industrial environments, offering protection against dust, moisture, and temperature extremes.

- Communication: Supports various communication protocols, such as Modbus and Ethernet, for integration into control systems.

Applications

- Predictive Maintenance: Detect faults early to prevent unplanned downtime and costly repairs.

- Condition Monitoring: Continuously monitor vibration levels for valuable insights into equipment health.

- Fault Diagnosis: Analyze vibration data to identify the root cause of mechanical problems.

- Process Optimization: Use vibration monitoring to enhance equipment performance and efficiency.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...