Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

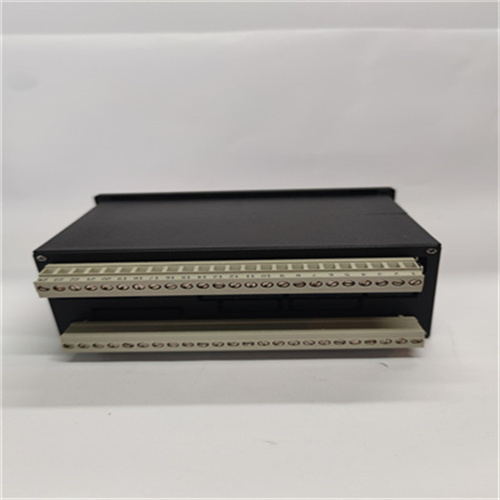

Woodward 5441-413 Relay interface Module

Manufacturer:Woodward

Product Number:5441-413

Condition:Relay interface module

Origin:USA

Dimensions:150 x 120 x 75mm

Weight:1.5 kg

Views:36

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 5441-413 is a high-performance industrial control module engineered for advanced automation and turbine management applications. Designed to operate within demanding environments, this unit integrates seamlessly into Woodward control systems, offering reliable performance in control, monitoring, and protection functions. Whether used in gas turbines, steam turbines, or industrial engines, the 5441-413 is known for its robust architecture, real-time data processing capabilities, and long-term operational stability.

The unit is typically part of Woodward’s MicroNet Plus control system series, which is widely adopted in power generation, marine propulsion, and mechanical drive applications. With its modular design and high processing speed, it helps ensure optimal control strategies and faster response times in critical industrial processes.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 5441-413 |

| Manufacturer | Woodward Inc. |

| Function | Control Module / CPU for MicroNet Systems |

| Processor Type | High-speed industrial microcontroller |

| Communication Interfaces | Ethernet, RS-232, RS-485, CAN |

| Input Voltage Range | 18–32 VDC |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95%, non-condensing |

| Mounting Type | Rack/Chassis Mountable |

| Certifications | CE, UL, CSA, RoHS compliant |

| Housing Material | Coated metal enclosure |

| Dimensions | 150 x 120 x 75mm |

| Weight | 1.5 kg |

Product Advantages

Industrial-grade reliability: Built to meet harsh environmental and operational conditions found in energy and industrial applications.

Modular integration: Supports flexible expansion and easy replacement within Woodward MicroNet Plus control platforms.

Advanced diagnostics: Equipped with fault detection, event logging, and health monitoring for proactive maintenance.

Real-time performance: High-speed data processing ensures accurate, deterministic control of turbine or engine systems.

Longevity and support: Long lifecycle design and strong backward compatibility with other Woodward components.

Secure communication: Features encrypted protocol compatibility and redundancy options for mission-critical applications.

Applications

Gas and steam turbine control in power generation facilities

Compressor and pump control for mechanical drive systems

Marine propulsion systems requiring reliable load-sharing and sequencing

Industrial engines used in oil & gas, mining, and utility sectors

Backup generator management in energy-critical infrastructures

Renewable energy integration with advanced load balancing strategies

Frequently Asked Questions (FAQ)

Q1: What is the main use of the Woodward 5441-413 module?

A1: It functions as a central control processing unit within MicroNet systems, managing turbines or engines in critical industrial applications.

Q2: Can this module be used in marine environments?

A2: Yes, it is suitable for marine applications, particularly in propulsion systems and auxiliary engine control, with appropriate environmental protection.

Q3: Is it compatible with legacy Woodward systems?

A3: It offers strong backward compatibility with previous MicroNet and MicroNet Plus generations, making upgrades straightforward.

Q4: What kind of diagnostics does it support?

A4: It supports internal diagnostics, error logging, and real-time health monitoring of system status and connected components.

Q5: Does the module support redundant operation?

A5: Yes, it can be configured for redundant CPU setups, increasing system reliability and uptime.

Q6: What communication protocols are supported?

A6: It supports Ethernet, serial (RS-232/485), and CAN protocols for flexible industrial communication.

Q7: How is the unit mounted in a control cabinet?

A7: The module is designed for rack or chassis mounting, following Woodward’s standard form factor for secure integration.

Q8: Can the firmware be updated in the field?

A8: Yes, the firmware can be upgraded via a secure interface while maintaining configuration integrity.

Q9: What kind of environments can it tolerate?

A9: It can operate in temperatures from -20°C to +70°C and up to 95% non-condensing humidity.

Q10: How long is the typical lifecycle of this product?

A10: The expected lifecycle is over 5 years under standard operational and maintenance practices, with support for extended periods from Woodward.

Woodward 5441-413 Relay interface Module

Manufacturer:Woodward

Product Number:5441-413

Condition:Relay interface module

Origin:USA

Dimensions:150 x 120 x 75mm

Weight:1.5 kg

Views:36

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 5441-413 is a high-performance industrial control module engineered for advanced automation and turbine management applications. Designed to operate within demanding environments, this unit integrates seamlessly into Woodward control systems, offering reliable performance in control, monitoring, and protection functions. Whether used in gas turbines, steam turbines, or industrial engines, the 5441-413 is known for its robust architecture, real-time data processing capabilities, and long-term operational stability.

The unit is typically part of Woodward’s MicroNet Plus control system series, which is widely adopted in power generation, marine propulsion, and mechanical drive applications. With its modular design and high processing speed, it helps ensure optimal control strategies and faster response times in critical industrial processes.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 5441-413 |

| Manufacturer | Woodward Inc. |

| Function | Control Module / CPU for MicroNet Systems |

| Processor Type | High-speed industrial microcontroller |

| Communication Interfaces | Ethernet, RS-232, RS-485, CAN |

| Input Voltage Range | 18–32 VDC |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95%, non-condensing |

| Mounting Type | Rack/Chassis Mountable |

| Certifications | CE, UL, CSA, RoHS compliant |

| Housing Material | Coated metal enclosure |

| Dimensions | 150 x 120 x 75mm |

| Weight | 1.5 kg |

Product Advantages

Industrial-grade reliability: Built to meet harsh environmental and operational conditions found in energy and industrial applications.

Modular integration: Supports flexible expansion and easy replacement within Woodward MicroNet Plus control platforms.

Advanced diagnostics: Equipped with fault detection, event logging, and health monitoring for proactive maintenance.

Real-time performance: High-speed data processing ensures accurate, deterministic control of turbine or engine systems.

Longevity and support: Long lifecycle design and strong backward compatibility with other Woodward components.

Secure communication: Features encrypted protocol compatibility and redundancy options for mission-critical applications.

Applications

Gas and steam turbine control in power generation facilities

Compressor and pump control for mechanical drive systems

Marine propulsion systems requiring reliable load-sharing and sequencing

Industrial engines used in oil & gas, mining, and utility sectors

Backup generator management in energy-critical infrastructures

Renewable energy integration with advanced load balancing strategies

Frequently Asked Questions (FAQ)

Q1: What is the main use of the Woodward 5441-413 module?

A1: It functions as a central control processing unit within MicroNet systems, managing turbines or engines in critical industrial applications.

Q2: Can this module be used in marine environments?

A2: Yes, it is suitable for marine applications, particularly in propulsion systems and auxiliary engine control, with appropriate environmental protection.

Q3: Is it compatible with legacy Woodward systems?

A3: It offers strong backward compatibility with previous MicroNet and MicroNet Plus generations, making upgrades straightforward.

Q4: What kind of diagnostics does it support?

A4: It supports internal diagnostics, error logging, and real-time health monitoring of system status and connected components.

Q5: Does the module support redundant operation?

A5: Yes, it can be configured for redundant CPU setups, increasing system reliability and uptime.

Q6: What communication protocols are supported?

A6: It supports Ethernet, serial (RS-232/485), and CAN protocols for flexible industrial communication.

Q7: How is the unit mounted in a control cabinet?

A7: The module is designed for rack or chassis mounting, following Woodward’s standard form factor for secure integration.

Q8: Can the firmware be updated in the field?

A8: Yes, the firmware can be upgraded via a secure interface while maintaining configuration integrity.

Q9: What kind of environments can it tolerate?

A9: It can operate in temperatures from -20°C to +70°C and up to 95% non-condensing humidity.

Q10: How long is the typical lifecycle of this product?

A10: The expected lifecycle is over 5 years under standard operational and maintenance practices, with support for extended periods from Woodward.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...