Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

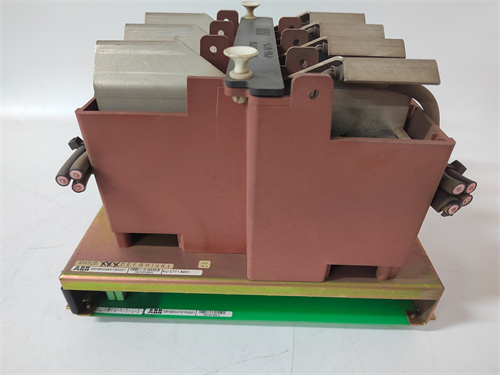

ABB PD D405 A101 3BHE041626R0101 Control Unit

Manufacturer:ABB

Product Number:PD D405 A101 3BHE041626R0101

Product Type:Control Unit

Origin:Sweden

Dimensions:220 × 160 × 40 mm

Weight:1.1 kg

Views:42

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PD D405 A101, part number 3BHE041626R0101, is a high-performance control unit developed for use in ABB’s advanced industrial control systems. It forms a critical part of ABB’s DCS (Distributed Control System) and Drive System architectures, ensuring precise and reliable process control across a variety of industrial environments. This control unit integrates seamlessly into existing ABB systems, offering advanced processing capabilities, robust signal interfacing, and durable design for mission-critical applications.

Equipped with powerful onboard processors, high-speed communication interfaces, and modular connectivity, the PD D405 A101 is designed to meet the high demands of automation in power generation, metals, mining, pulp and paper, and chemical processing industries. It plays a central role in executing control logic, managing I/O modules, and facilitating communication between field devices and supervisory systems.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | PD D405 A101 Control Unit |

| Part Number | 3BHE041626R0101 |

| Product Type | Control Unit / Central Processing Board |

| System Compatibility | ABB Drive Systems, ABB DCS (e.g., AC800PEC, Freelance) |

| Processor | High-speed embedded controller |

| Communication Protocols | CAN, Ethernet, Optical Link |

| Input/Output Support | Works with multiple I/O extension modules |

| Memory | Onboard flash + volatile RAM for fast cycle processing |

| Built-in Diagnostics | Yes – LED indicators and system self-test |

| Power Supply | Supplied through system backplane or dedicated connector |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -40°C to +70°C |

| Relative Humidity | 5% to 95%, non-condensing |

| Vibration Resistance | In accordance with IEC 60068-2-6 |

| Certifications | CE, UL, RoHS, CSA |

| Mounting Type | Backplane rack mount |

| Dimensions (H × W × D) | 220 × 160 × 40 mm |

| Weight | 1.1 kg |

| Enclosure Rating | IP20 (when installed in cabinet enclosure) |

Applications

The ABB PD D405 A101 control unit is a versatile component utilized across many industries where precision control, high availability, and fast communication are essential. Key applications include:

Power Generation

Controls turbine performance, excitation systems, and auxiliary equipment in thermal, hydro, and wind power plants.

Metals and Mining

Manages complex drive systems for rolling mills, hoists, and crushers, ensuring speed regulation and torque control.

Chemical and Petrochemical Plants

Offers real-time process control and communication with field instruments in batch and continuous operations.

Pulp and Paper Industry

Coordinates multiple drives and sections across paper machines, enhancing production efficiency.

Marine and Offshore Systems

Handles propulsion system control and load sharing in marine applications.

Industrial Automation and Robotics

Ensures high-speed control for motion systems, conveyor belts, and robotic arms.

Key Advantages

Advanced Processing Power

Equipped with high-speed processors for real-time control tasks in drive and automation systems.

Modular and Scalable

Easily integrates with ABB’s modular systems, allowing expansion with additional I/O or communication modules.

Reliable Communication Interfaces

Supports multiple industrial communication standards including CAN, Ethernet, and fiber optics.

Robust Industrial Design

Engineered to withstand vibration, electrical noise, and high temperatures common in heavy industries.

Built-in Diagnostics

Onboard status indicators and internal system tests simplify troubleshooting and reduce downtime.

Plug-and-Play Integration

Seamless compatibility with ABB’s drive and DCS ecosystems accelerates commissioning.

Long Lifecycle Support

Backed by ABB’s global support and long-term product lifecycle services.

Reduced Downtime

High reliability and error-resilient architecture help maximize plant uptime.

Frequently Asked Questions (FAQ)

Q: What is the primary function of the PD D405 A101?

A: It acts as the main control processor in ABB drive systems or DCS environments, executing control logic and managing I/O and communication.

Q: Can this control unit be used in redundant configurations?

A: Yes, the PD D405 A101 can be configured for redundancy when paired with compatible hardware.

Q: Is this module hot-swappable?

A: No, the system must be powered down before installing or replacing the unit.

Q: Which ABB systems support the PD D405 A101?

A: It is commonly used in ABB AC800PEC, Freelance, and other industrial automation systems.

Q: What communication protocols are supported?

A: Ethernet, CAN, and Optical Link (fiber optic) protocols are supported.

Q: Is the unit field-configurable?

A: Configuration is typically done through ABB’s engineering tools such as Control Builder or Drive Composer.

Q: What is the power requirement of this unit?

A: It is powered via system backplane, and does not require an external power supply.

Q: Does the unit support diagnostic LEDs?

A: Yes, LED indicators provide real-time status and fault diagnostics.

Q: How is it mounted in the system?

A: It is designed for backplane mounting inside ABB control or drive racks.

Q: What’s the typical service life of the PD D405 A101?

A: With proper environmental conditions and regular maintenance, it can operate reliably for 10–15+ years.

ABB PD D405 A101 3BHE041626R0101 Control Unit

Manufacturer:ABB

Product Number:PD D405 A101 3BHE041626R0101

Product Type:Control Unit

Origin:Sweden

Dimensions:220 × 160 × 40 mm

Weight:1.1 kg

Views:42

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PD D405 A101, part number 3BHE041626R0101, is a high-performance control unit developed for use in ABB’s advanced industrial control systems. It forms a critical part of ABB’s DCS (Distributed Control System) and Drive System architectures, ensuring precise and reliable process control across a variety of industrial environments. This control unit integrates seamlessly into existing ABB systems, offering advanced processing capabilities, robust signal interfacing, and durable design for mission-critical applications.

Equipped with powerful onboard processors, high-speed communication interfaces, and modular connectivity, the PD D405 A101 is designed to meet the high demands of automation in power generation, metals, mining, pulp and paper, and chemical processing industries. It plays a central role in executing control logic, managing I/O modules, and facilitating communication between field devices and supervisory systems.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | PD D405 A101 Control Unit |

| Part Number | 3BHE041626R0101 |

| Product Type | Control Unit / Central Processing Board |

| System Compatibility | ABB Drive Systems, ABB DCS (e.g., AC800PEC, Freelance) |

| Processor | High-speed embedded controller |

| Communication Protocols | CAN, Ethernet, Optical Link |

| Input/Output Support | Works with multiple I/O extension modules |

| Memory | Onboard flash + volatile RAM for fast cycle processing |

| Built-in Diagnostics | Yes – LED indicators and system self-test |

| Power Supply | Supplied through system backplane or dedicated connector |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -40°C to +70°C |

| Relative Humidity | 5% to 95%, non-condensing |

| Vibration Resistance | In accordance with IEC 60068-2-6 |

| Certifications | CE, UL, RoHS, CSA |

| Mounting Type | Backplane rack mount |

| Dimensions (H × W × D) | 220 × 160 × 40 mm |

| Weight | 1.1 kg |

| Enclosure Rating | IP20 (when installed in cabinet enclosure) |

Applications

The ABB PD D405 A101 control unit is a versatile component utilized across many industries where precision control, high availability, and fast communication are essential. Key applications include:

Power Generation

Controls turbine performance, excitation systems, and auxiliary equipment in thermal, hydro, and wind power plants.

Metals and Mining

Manages complex drive systems for rolling mills, hoists, and crushers, ensuring speed regulation and torque control.

Chemical and Petrochemical Plants

Offers real-time process control and communication with field instruments in batch and continuous operations.

Pulp and Paper Industry

Coordinates multiple drives and sections across paper machines, enhancing production efficiency.

Marine and Offshore Systems

Handles propulsion system control and load sharing in marine applications.

Industrial Automation and Robotics

Ensures high-speed control for motion systems, conveyor belts, and robotic arms.

Key Advantages

Advanced Processing Power

Equipped with high-speed processors for real-time control tasks in drive and automation systems.

Modular and Scalable

Easily integrates with ABB’s modular systems, allowing expansion with additional I/O or communication modules.

Reliable Communication Interfaces

Supports multiple industrial communication standards including CAN, Ethernet, and fiber optics.

Robust Industrial Design

Engineered to withstand vibration, electrical noise, and high temperatures common in heavy industries.

Built-in Diagnostics

Onboard status indicators and internal system tests simplify troubleshooting and reduce downtime.

Plug-and-Play Integration

Seamless compatibility with ABB’s drive and DCS ecosystems accelerates commissioning.

Long Lifecycle Support

Backed by ABB’s global support and long-term product lifecycle services.

Reduced Downtime

High reliability and error-resilient architecture help maximize plant uptime.

Frequently Asked Questions (FAQ)

Q: What is the primary function of the PD D405 A101?

A: It acts as the main control processor in ABB drive systems or DCS environments, executing control logic and managing I/O and communication.

Q: Can this control unit be used in redundant configurations?

A: Yes, the PD D405 A101 can be configured for redundancy when paired with compatible hardware.

Q: Is this module hot-swappable?

A: No, the system must be powered down before installing or replacing the unit.

Q: Which ABB systems support the PD D405 A101?

A: It is commonly used in ABB AC800PEC, Freelance, and other industrial automation systems.

Q: What communication protocols are supported?

A: Ethernet, CAN, and Optical Link (fiber optic) protocols are supported.

Q: Is the unit field-configurable?

A: Configuration is typically done through ABB’s engineering tools such as Control Builder or Drive Composer.

Q: What is the power requirement of this unit?

A: It is powered via system backplane, and does not require an external power supply.

Q: Does the unit support diagnostic LEDs?

A: Yes, LED indicators provide real-time status and fault diagnostics.

Q: How is it mounted in the system?

A: It is designed for backplane mounting inside ABB control or drive racks.

Q: What’s the typical service life of the PD D405 A101?

A: With proper environmental conditions and regular maintenance, it can operate reliably for 10–15+ years.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...