Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

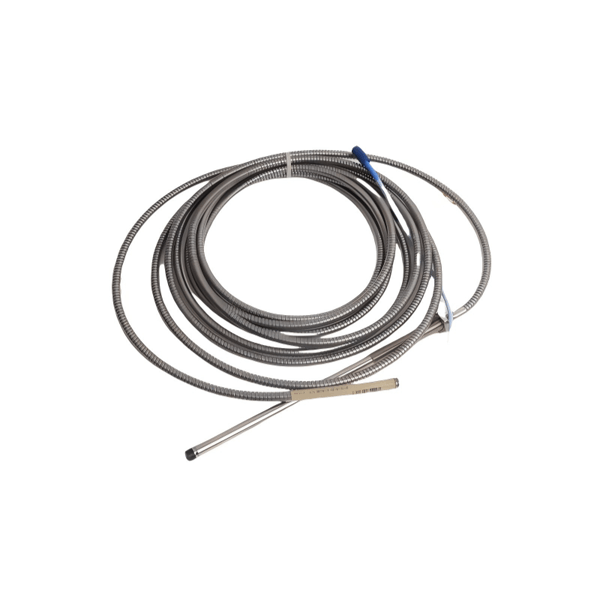

Bently Nevada 330104-00-05-90-02-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330104-00-05-90-02-00

Condition:3300 XL 8 mm Proximity Probe

Origin:USA

Cable length:9 m

Weight:2.907 kg

Views:24

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-00-05-90-02-00 is a high-performance vibration sensor used to monitor the health of industrial machinery. It is part of the renowned Bently Nevada 3300 series, designed to offer reliable, precise, and continuous monitoring of equipment like motors, pumps, turbines, and compressors. This sensor plays a critical role in predictive maintenance systems by detecting early signs of failure in rotating equipment. It is designed for use in demanding industrial environments, ensuring that operators can make data-driven decisions that help prevent costly downtimes and repairs.

Bently Nevada is known for its robust and reliable solutions, and the 330104 series is no exception. With advanced features, this product provides high sensitivity and a broad measurement range, making it suitable for various applications across multiple industries.

Technical Specifications

| Specification | Details |

|---|---|

| Model Number | 330104-00-05-90-02-00 |

| Vibration Type | Accelerometer |

| Operating Range | 0.1 Hz to 10 kHz |

| Sensitivity | 100 mV/g |

| Measurement Type | Vibration, Shock |

| Output Type | 4-20 mA or 0-10 V DC |

| Mounting Type | Threaded or Welded |

| Weight | 2.907 kg |

| Cable length | 9 m |

| Operating Temperature | -40°C to +85°C |

| Voltage | 24 VDC |

| Current | 30 mA (max) |

| Material | Stainless Steel |

Product Applications

The Bently Nevada 330104-00-05-90-02-00 vibration sensor is widely used in industries where continuous monitoring of rotating equipment is critical. Some of the main applications include:

Industrial Machinery Monitoring: Used to monitor machinery such as compressors, turbines, motors, and pumps, ensuring their condition is optimal.

Oil and Gas Industry: Used for monitoring critical equipment in offshore platforms and refineries, ensuring no failure occurs during operations.

Power Generation: Plays an essential role in the continuous monitoring of power plant turbines and other essential equipment.

Mining and Metallurgy: Ensures smooth operation of machinery in heavy-duty environments where continuous equipment performance is essential.

Manufacturing: Applied in the maintenance of production lines and equipment, reducing unplanned downtime.

Advantages of Bently Nevada 330104-00-05-90-02-00

High Sensitivity: The sensor offers a high degree of sensitivity, which allows it to detect even small changes in vibration, providing early warning signals of equipment deterioration.

Rugged Design: Built to withstand harsh industrial environments, the 330104 series is durable and reliable in extreme conditions.

Long-Lasting Performance: Designed for long operational lifespans, minimizing the need for frequent maintenance.

Real-time Monitoring: Provides continuous feedback, which helps in predictive maintenance, reducing the need for unscheduled repairs and saving costs.

Ease of Integration: The sensor can easily be integrated into existing vibration monitoring systems, ensuring minimal disruption during installation.

Versatile: Suitable for use with a wide range of industrial equipment across various sectors.

FAQ

What is the purpose of the Bently Nevada 330104-00-05-90-02-00 sensor?

-

This sensor is designed to measure vibration and shock in industrial machinery, providing vital data for predictive maintenance.

-

What is the operating temperature range of this sensor?

-

The sensor can operate in temperatures ranging from -40°C to +85°C, making it suitable for extreme environments.

-

How is this sensor mounted?

-

The Bently Nevada 330104 can be mounted using threaded or welded attachments, offering flexibility in installation.

-

What industries use the Bently Nevada 330104-00-05-90-02-00?

-

It is used across industries such as oil & gas, power generation, mining, metallurgy, and manufacturing.

-

Can this sensor integrate with existing systems?

-

Yes, it is designed for easy integration into existing vibration monitoring setups.

-

What type of output does the sensor provide?

-

The sensor provides an output of either 4-20 mA or 0-10 V DC, depending on the configuration.

-

What is the weight of this sensor?

-

The sensor weighs 2.907 kg.

-

What is the sensitivity of the sensor?

-

The sensor has a sensitivity of 100 mV/g, allowing for precise measurement of vibration levels.

-

Can this sensor be used for both vibration and shock monitoring?

-

Yes, it is capable of monitoring both vibration and shock, providing comprehensive data on equipment health.

-

What is the typical lifespan of this sensor?

-

With its rugged construction and high durability, the sensor is designed for long-lasting performance, often exceeding many years of service.

-

Bently Nevada 330104-00-05-90-02-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330104-00-05-90-02-00

Condition:3300 XL 8 mm Proximity Probe

Origin:USA

Cable length:9 m

Weight:2.907 kg

Views:24

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-00-05-90-02-00 is a high-performance vibration sensor used to monitor the health of industrial machinery. It is part of the renowned Bently Nevada 3300 series, designed to offer reliable, precise, and continuous monitoring of equipment like motors, pumps, turbines, and compressors. This sensor plays a critical role in predictive maintenance systems by detecting early signs of failure in rotating equipment. It is designed for use in demanding industrial environments, ensuring that operators can make data-driven decisions that help prevent costly downtimes and repairs.

Bently Nevada is known for its robust and reliable solutions, and the 330104 series is no exception. With advanced features, this product provides high sensitivity and a broad measurement range, making it suitable for various applications across multiple industries.

Technical Specifications

| Specification | Details |

|---|---|

| Model Number | 330104-00-05-90-02-00 |

| Vibration Type | Accelerometer |

| Operating Range | 0.1 Hz to 10 kHz |

| Sensitivity | 100 mV/g |

| Measurement Type | Vibration, Shock |

| Output Type | 4-20 mA or 0-10 V DC |

| Mounting Type | Threaded or Welded |

| Weight | 2.907 kg |

| Cable length | 9 m |

| Operating Temperature | -40°C to +85°C |

| Voltage | 24 VDC |

| Current | 30 mA (max) |

| Material | Stainless Steel |

Product Applications

The Bently Nevada 330104-00-05-90-02-00 vibration sensor is widely used in industries where continuous monitoring of rotating equipment is critical. Some of the main applications include:

Industrial Machinery Monitoring: Used to monitor machinery such as compressors, turbines, motors, and pumps, ensuring their condition is optimal.

Oil and Gas Industry: Used for monitoring critical equipment in offshore platforms and refineries, ensuring no failure occurs during operations.

Power Generation: Plays an essential role in the continuous monitoring of power plant turbines and other essential equipment.

Mining and Metallurgy: Ensures smooth operation of machinery in heavy-duty environments where continuous equipment performance is essential.

Manufacturing: Applied in the maintenance of production lines and equipment, reducing unplanned downtime.

Advantages of Bently Nevada 330104-00-05-90-02-00

High Sensitivity: The sensor offers a high degree of sensitivity, which allows it to detect even small changes in vibration, providing early warning signals of equipment deterioration.

Rugged Design: Built to withstand harsh industrial environments, the 330104 series is durable and reliable in extreme conditions.

Long-Lasting Performance: Designed for long operational lifespans, minimizing the need for frequent maintenance.

Real-time Monitoring: Provides continuous feedback, which helps in predictive maintenance, reducing the need for unscheduled repairs and saving costs.

Ease of Integration: The sensor can easily be integrated into existing vibration monitoring systems, ensuring minimal disruption during installation.

Versatile: Suitable for use with a wide range of industrial equipment across various sectors.

FAQ

What is the purpose of the Bently Nevada 330104-00-05-90-02-00 sensor?

-

This sensor is designed to measure vibration and shock in industrial machinery, providing vital data for predictive maintenance.

-

What is the operating temperature range of this sensor?

-

The sensor can operate in temperatures ranging from -40°C to +85°C, making it suitable for extreme environments.

-

How is this sensor mounted?

-

The Bently Nevada 330104 can be mounted using threaded or welded attachments, offering flexibility in installation.

-

What industries use the Bently Nevada 330104-00-05-90-02-00?

-

It is used across industries such as oil & gas, power generation, mining, metallurgy, and manufacturing.

-

Can this sensor integrate with existing systems?

-

Yes, it is designed for easy integration into existing vibration monitoring setups.

-

What type of output does the sensor provide?

-

The sensor provides an output of either 4-20 mA or 0-10 V DC, depending on the configuration.

-

What is the weight of this sensor?

-

The sensor weighs 2.907 kg.

-

What is the sensitivity of the sensor?

-

The sensor has a sensitivity of 100 mV/g, allowing for precise measurement of vibration levels.

-

Can this sensor be used for both vibration and shock monitoring?

-

Yes, it is capable of monitoring both vibration and shock, providing comprehensive data on equipment health.

-

What is the typical lifespan of this sensor?

-

With its rugged construction and high durability, the sensor is designed for long-lasting performance, often exceeding many years of service.

-

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...