Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

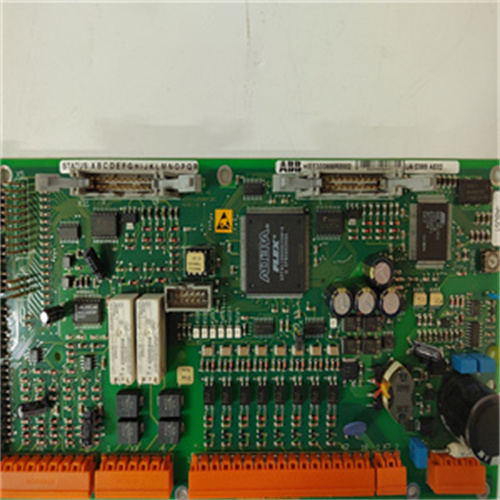

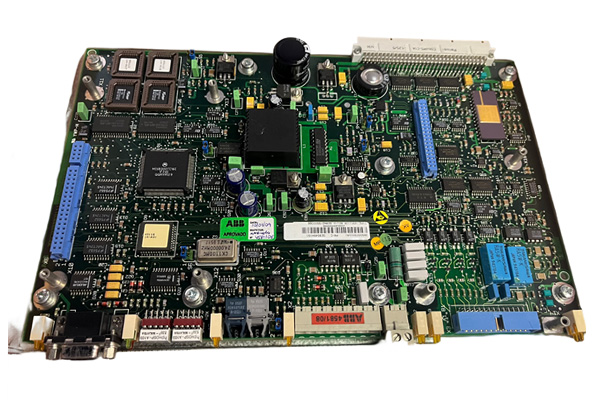

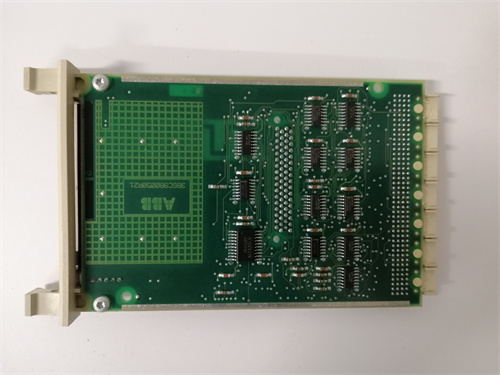

ABB PXAK402 3BSE011789R1 DCS Control System

Manufacturer:ABB

Product Number:PXAK402 3BSE011789R1

Product Type:DCS Control System

Origin:Sweden

Dimensions:45 × 120 × 110 mm

Weight:0.3 kg

Views:35

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PXAK402 (Part No. 3BSE011789R1) is a key module within ABB’s Distributed Control System (DCS) architecture, designed to ensure robust and reliable process automation in demanding industrial environments. It plays a vital role in signal interfacing and process I/O handling, enabling seamless data flow between field devices and control processors in the ABB System 800xA or Advant Master systems.

Known for its precision, compact footprint, and integration flexibility, the PXAK402 is typically installed in S800 I/O stations and supports remote I/O configurations, making it ideal for applications where scalability, redundancy, and safety are essential.

Whether it’s deployed in a power generation plant, chemical refinery, or heavy industrial setup, the PXAK402 provides consistent and dependable performance, contributing to ABB’s mission of delivering intelligent automation and operational excellence.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Name | DCS Control System Module |

| Model | PXAK402 |

| Part Number | 3BSE011789R1 |

| Manufacturer | ABB |

| System Compatibility | System 800xA, S800 I/O, Advant Master |

| Function | Communication interface for I/O stations |

| Communication Protocol | Advant Fieldbus 100 (AF100), PROFIBUS DP |

| Mounting Type | DIN-rail or cabinet-mounted |

| Redundancy Support | Yes, supports redundant I/O and communication paths |

| Power Supply Voltage | 24 VDC |

| Power Consumption | Approx. 4 W |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +70°C |

| Ingress Protection | IP20 |

| Certifications | CE, RoHS, IEC 61131-2, UL, CSA |

| Dimensions (W × H × D) | 45 × 120 × 110 mm |

| Weight | 0.3 kg |

Product Applications

The ABB PXAK402 module is used extensively in industrial applications where control reliability and field communication are critical. Its use cases span a wide array of automation environments:

Thermal and Hydropower Plants – I/O interface and communication for turbine and auxiliary systems.

Chemical and Petrochemical Plants – Connecting field devices like flow meters, pressure transmitters, and control valves to central controllers.

Steel and Mining Industries – Used in blast furnace monitoring, drive systems, and material handling equipment.

Pulp and Paper Mills – Enables distributed I/O systems for section-wise control and diagnostics.

Oil & Gas Facilities – Integration with remote instrumentation and redundant safety I/O panels.

Automated Factories – Provides process I/O connectivity with reliable communication to PLCs and SCADA.

Product Advantages

Seamless System Integration: Fully compatible with ABB’s 800xA, S800 I/O, and Advant Master systems, allowing plug-and-play architecture.

Redundancy-Ready: Supports redundant operation for mission-critical applications, reducing downtime risk.

Compact Design: Saves cabinet space with its slim, DIN-rail mountable profile.

Flexible Protocols: Offers dual communication compatibility with AF100 and PROFIBUS, expanding interoperability.

Fast Response Time: Enables high-speed data exchange, making it suitable for time-sensitive process control.

Easy Maintenance: Hot-swappable in most configurations and supports self-diagnostics for quick fault detection.

Reliable Operation in Harsh Conditions: With industrial-grade build quality and wide temperature tolerance.

Scalable Architecture: Can be used in both small-scale installations and large distributed networks.

Long-Term Availability: Supported global supply and lifecycle management.

Safety-Compliant: Designed in accordance with international safety and EMC standards.

Frequently Asked Questions (FAQ)

What is the main function of the PXAK402 module?

It serves as a communication interface between the control system and field-level I/O devices within ABB’s DCS architecture.

Is the PXAK402 compatible with PROFIBUS networks?

Yes, it supports both PROFIBUS DP and Advant Fieldbus 100, allowing integration into various network topologies.

Can PXAK402 be used in redundant configurations?

Absolutely. The module is designed to support redundancy, ensuring continuous operation in critical systems.

What control systems is this module compatible with?

It integrates seamlessly with ABB System 800xA, Advant Master, and S800 I/O systems.

Is hot-swapping supported on PXAK402?

Yes, when installed properly, the module can be replaced without shutting down the entire system.

Does PXAK402 require special software for configuration?

Yes, configuration and diagnostics are performed using ABB’s engineering tools, typically via 800xA or Advant configuration suites.

Can it communicate with third-party PLCs?

It can, provided that standard fieldbus protocols like PROFIBUS DP are used and communication parameters are properly mapped.

Is it suitable for remote I/O stations?

Yes, PXAK402 is often used in distributed I/O setups for remote or field-level automation.

What is the IP rating of this module?

The PXAK402 itself has an IP20 rating and should be installed within a protected control cabinet.

How is it mounted in a control panel?

It is designed for DIN-rail mounting but may also be secured in custom cabinet layouts depending on the system design.

ABB PXAK402 3BSE011789R1 DCS Control System

Manufacturer:ABB

Product Number:PXAK402 3BSE011789R1

Product Type:DCS Control System

Origin:Sweden

Dimensions:45 × 120 × 110 mm

Weight:0.3 kg

Views:35

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PXAK402 (Part No. 3BSE011789R1) is a key module within ABB’s Distributed Control System (DCS) architecture, designed to ensure robust and reliable process automation in demanding industrial environments. It plays a vital role in signal interfacing and process I/O handling, enabling seamless data flow between field devices and control processors in the ABB System 800xA or Advant Master systems.

Known for its precision, compact footprint, and integration flexibility, the PXAK402 is typically installed in S800 I/O stations and supports remote I/O configurations, making it ideal for applications where scalability, redundancy, and safety are essential.

Whether it’s deployed in a power generation plant, chemical refinery, or heavy industrial setup, the PXAK402 provides consistent and dependable performance, contributing to ABB’s mission of delivering intelligent automation and operational excellence.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Name | DCS Control System Module |

| Model | PXAK402 |

| Part Number | 3BSE011789R1 |

| Manufacturer | ABB |

| System Compatibility | System 800xA, S800 I/O, Advant Master |

| Function | Communication interface for I/O stations |

| Communication Protocol | Advant Fieldbus 100 (AF100), PROFIBUS DP |

| Mounting Type | DIN-rail or cabinet-mounted |

| Redundancy Support | Yes, supports redundant I/O and communication paths |

| Power Supply Voltage | 24 VDC |

| Power Consumption | Approx. 4 W |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +70°C |

| Ingress Protection | IP20 |

| Certifications | CE, RoHS, IEC 61131-2, UL, CSA |

| Dimensions (W × H × D) | 45 × 120 × 110 mm |

| Weight | 0.3 kg |

Product Applications

The ABB PXAK402 module is used extensively in industrial applications where control reliability and field communication are critical. Its use cases span a wide array of automation environments:

Thermal and Hydropower Plants – I/O interface and communication for turbine and auxiliary systems.

Chemical and Petrochemical Plants – Connecting field devices like flow meters, pressure transmitters, and control valves to central controllers.

Steel and Mining Industries – Used in blast furnace monitoring, drive systems, and material handling equipment.

Pulp and Paper Mills – Enables distributed I/O systems for section-wise control and diagnostics.

Oil & Gas Facilities – Integration with remote instrumentation and redundant safety I/O panels.

Automated Factories – Provides process I/O connectivity with reliable communication to PLCs and SCADA.

Product Advantages

Seamless System Integration: Fully compatible with ABB’s 800xA, S800 I/O, and Advant Master systems, allowing plug-and-play architecture.

Redundancy-Ready: Supports redundant operation for mission-critical applications, reducing downtime risk.

Compact Design: Saves cabinet space with its slim, DIN-rail mountable profile.

Flexible Protocols: Offers dual communication compatibility with AF100 and PROFIBUS, expanding interoperability.

Fast Response Time: Enables high-speed data exchange, making it suitable for time-sensitive process control.

Easy Maintenance: Hot-swappable in most configurations and supports self-diagnostics for quick fault detection.

Reliable Operation in Harsh Conditions: With industrial-grade build quality and wide temperature tolerance.

Scalable Architecture: Can be used in both small-scale installations and large distributed networks.

Long-Term Availability: Supported global supply and lifecycle management.

Safety-Compliant: Designed in accordance with international safety and EMC standards.

Frequently Asked Questions (FAQ)

What is the main function of the PXAK402 module?

It serves as a communication interface between the control system and field-level I/O devices within ABB’s DCS architecture.

Is the PXAK402 compatible with PROFIBUS networks?

Yes, it supports both PROFIBUS DP and Advant Fieldbus 100, allowing integration into various network topologies.

Can PXAK402 be used in redundant configurations?

Absolutely. The module is designed to support redundancy, ensuring continuous operation in critical systems.

What control systems is this module compatible with?

It integrates seamlessly with ABB System 800xA, Advant Master, and S800 I/O systems.

Is hot-swapping supported on PXAK402?

Yes, when installed properly, the module can be replaced without shutting down the entire system.

Does PXAK402 require special software for configuration?

Yes, configuration and diagnostics are performed using ABB’s engineering tools, typically via 800xA or Advant configuration suites.

Can it communicate with third-party PLCs?

It can, provided that standard fieldbus protocols like PROFIBUS DP are used and communication parameters are properly mapped.

Is it suitable for remote I/O stations?

Yes, PXAK402 is often used in distributed I/O setups for remote or field-level automation.

What is the IP rating of this module?

The PXAK402 itself has an IP20 rating and should be installed within a protected control cabinet.

How is it mounted in a control panel?

It is designed for DIN-rail mounting but may also be secured in custom cabinet layouts depending on the system design.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...