Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

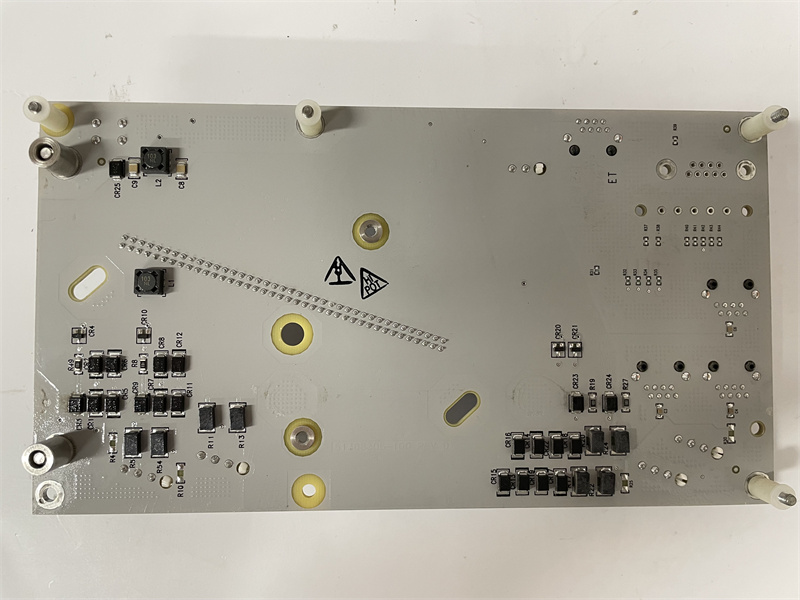

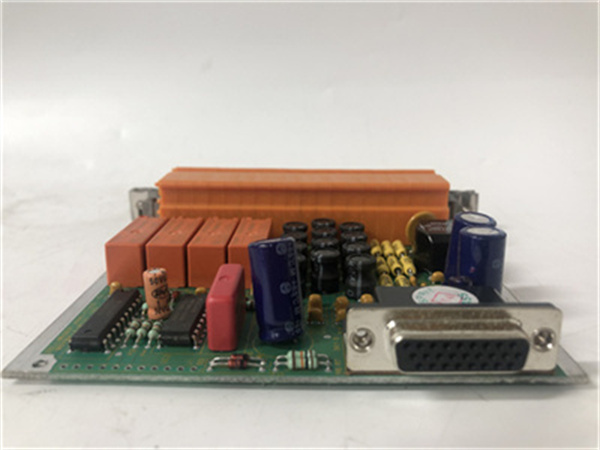

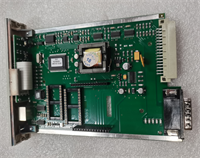

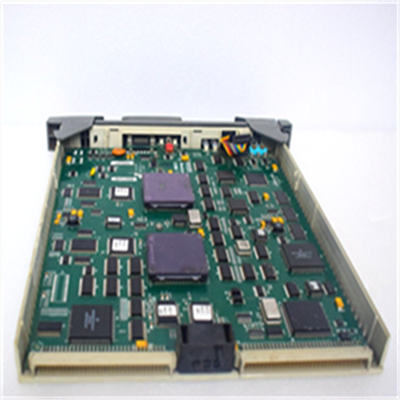

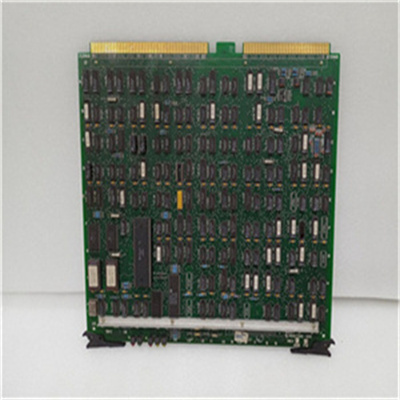

Honeywell HC900 Controller 900C71-0144-00 CPU Module

Brand: Honeywell

Model Number:ControlEdge™ HC900 process automation controller

Part Number: 900C71-0144-00

Type: CPU Module

Product Origin: United States

Dimensions: 12.7 x 10.16 x 6.35 cm (5 x 4 x 2.5 inches)

Weight: 0.45 kg (1 pound)

Certificate: UL, CE

Warranty: 2 years

Product Description

The Honeywell ControlEdge HC900 Controller is an advanced loop and logic controller designed with a modular structure to meet the control and data management requirements of a wide array of process equipment. When used in conjunction with the optional 900 Control Station operator interface, which seamlessly integrates with the controller’s database, configuration and setup times are minimized. This potent combination, coupled with Honeywell’s established control technology, offers users an ideal solution for process control. Furthermore, it provides open Ethernet connectivity via the Modbus TCP Protocol, enabling network access through various HMI/SCADA software solutions. The program execution environment is safeguarded by an independent watchdog timer.

Designer Software

The controller configuration process is made simple through the use of the easy-to-use Windows-based Designer software, which can be operated over Ethernet or RS485 ports (isolated). This software is available in both English and Chinese language versions. It offers advanced monitoring functions for debugging, allows for real-time process configuration adjustments while maintaining process control, facilitates the upload of the complete, annotated graphic controller configuration, and provides a wide range of reports for comprehensive documentation.

ControlEdge HC900 Controller Features

The ControlEdge HC900 Controller delivers superior PID loop control and more robust analog processing compared to most logic controllers, all without compromising logic performance. It achieves this through a separate, high-speed scan cycle that executes a diverse set of logic and calculation function blocks. Additionally, logic blocks can execute in the same scan cycle as analog function blocks for time-critical events. These function blocks can be seamlessly integrated into a unified analog and logic control strategy to ensure uncompromising control performance.

For More Information

For more detailed specifications, please refer to the following specification sheets:

-

ControlEdge 900 Platform Modules

- Specs 51-52-03-41

-

Designer Software

- Specs 51-52-03-43

Applications

-

Mining & Metals

- Furnaces

- Kilns

- Boilers

-

Chemicals

- Extruders

- Autoclaves

-

Pharmaceuticals

- Sterilizers

- Dryers

-

Rail/Infrastructure

- Burner Management

- HVAC/Data Centers

- Combustion Control

-

Pulp & Paper

- Emergency Shutdown

-

Cement & Glass

- Pipeline Monitoring

-

Power

- Spill Prevention

Features Summary

- Supports Split Rack Redundancy

- Supports Honeywell FDM (Field Device Manager) using HART IP

- Supports HART function blocks (Command 3 and 48) Note: UIO Module is required for HART support

- Non-redundant and Redundant Architectures

- Sequence of events support (SOE)

- Redundant and Non-redundant Safety Universal IO

- PID Control with advanced Accutune III auto-tuning

- Safety peer communication between ControlEdge HC900 controllers

- External watchdog timer with independent clocks that detect spurious CPU lockups

- Adjustable recipe pool memory lets you allocate memory for recipes, SP Profiles, sequences, and schedules to meet your needs

- Up to 4608 points with remote I/O

- Boolean Logic programming. Robust assortment of over 100 algorithms

- Advanced Floating Point Math Functions

- Extensive alarm and event monitoring

- Up to 2304 galvanically Isolated, Analog Inputs

- Up to 1008 redundant UIO points

- New I/O voting and output validation function blocks

- Remote I/O Racks with wire for extended distance

- Star or Ring topology on IO network using recommended switches

- Scanner and I/O Insert/Remove under power

- LED on/off indicators on digital I/O

- Graphic Function Block Configuration

- Open 10MB or 10/100MB Ethernet interface using Modbus/TCP. Peer-to-peer communications via Ethernet

- E-mail alarm/event messaging on priority

- Ramp/Soak Setpoint Programmers

- Setpoint Schedulers with multiple outputs

- Sequencers with 16 Outputs each

- Modbus read/write parameters assignable to either fixed or custom addresses for access by HMI or supervisory software

- Modbus TCP Initiator

- Gas flow function blocks per American Gas Association specs (non-Safety configurations only)

- Calendar block for triggering events

- Non-interfering process/safety worksheets capable of handling process and safety configurations

- Built-in Version Control

- Fast updates – 10 ms digital and UIO (900U02-xxxx) 100 ms analog capable Note: Low-Level AI updates @ 0.5 sec.

Honeywell HC900 Controller 900C71-0144-00 CPU Module

Brand: Honeywell

Model Number:ControlEdge™ HC900 process automation controller

Part Number: 900C71-0144-00

Type: CPU Module

Product Origin: United States

Dimensions: 12.7 x 10.16 x 6.35 cm (5 x 4 x 2.5 inches)

Weight: 0.45 kg (1 pound)

Certificate: UL, CE

Warranty: 2 years

Product Description

The Honeywell ControlEdge HC900 Controller is an advanced loop and logic controller designed with a modular structure to meet the control and data management requirements of a wide array of process equipment. When used in conjunction with the optional 900 Control Station operator interface, which seamlessly integrates with the controller’s database, configuration and setup times are minimized. This potent combination, coupled with Honeywell’s established control technology, offers users an ideal solution for process control. Furthermore, it provides open Ethernet connectivity via the Modbus TCP Protocol, enabling network access through various HMI/SCADA software solutions. The program execution environment is safeguarded by an independent watchdog timer.

Designer Software

The controller configuration process is made simple through the use of the easy-to-use Windows-based Designer software, which can be operated over Ethernet or RS485 ports (isolated). This software is available in both English and Chinese language versions. It offers advanced monitoring functions for debugging, allows for real-time process configuration adjustments while maintaining process control, facilitates the upload of the complete, annotated graphic controller configuration, and provides a wide range of reports for comprehensive documentation.

ControlEdge HC900 Controller Features

The ControlEdge HC900 Controller delivers superior PID loop control and more robust analog processing compared to most logic controllers, all without compromising logic performance. It achieves this through a separate, high-speed scan cycle that executes a diverse set of logic and calculation function blocks. Additionally, logic blocks can execute in the same scan cycle as analog function blocks for time-critical events. These function blocks can be seamlessly integrated into a unified analog and logic control strategy to ensure uncompromising control performance.

For More Information

For more detailed specifications, please refer to the following specification sheets:

-

ControlEdge 900 Platform Modules

- Specs 51-52-03-41

-

Designer Software

- Specs 51-52-03-43

Applications

-

Mining & Metals

- Furnaces

- Kilns

- Boilers

-

Chemicals

- Extruders

- Autoclaves

-

Pharmaceuticals

- Sterilizers

- Dryers

-

Rail/Infrastructure

- Burner Management

- HVAC/Data Centers

- Combustion Control

-

Pulp & Paper

- Emergency Shutdown

-

Cement & Glass

- Pipeline Monitoring

-

Power

- Spill Prevention

Features Summary

- Supports Split Rack Redundancy

- Supports Honeywell FDM (Field Device Manager) using HART IP

- Supports HART function blocks (Command 3 and 48) Note: UIO Module is required for HART support

- Non-redundant and Redundant Architectures

- Sequence of events support (SOE)

- Redundant and Non-redundant Safety Universal IO

- PID Control with advanced Accutune III auto-tuning

- Safety peer communication between ControlEdge HC900 controllers

- External watchdog timer with independent clocks that detect spurious CPU lockups

- Adjustable recipe pool memory lets you allocate memory for recipes, SP Profiles, sequences, and schedules to meet your needs

- Up to 4608 points with remote I/O

- Boolean Logic programming. Robust assortment of over 100 algorithms

- Advanced Floating Point Math Functions

- Extensive alarm and event monitoring

- Up to 2304 galvanically Isolated, Analog Inputs

- Up to 1008 redundant UIO points

- New I/O voting and output validation function blocks

- Remote I/O Racks with wire for extended distance

- Star or Ring topology on IO network using recommended switches

- Scanner and I/O Insert/Remove under power

- LED on/off indicators on digital I/O

- Graphic Function Block Configuration

- Open 10MB or 10/100MB Ethernet interface using Modbus/TCP. Peer-to-peer communications via Ethernet

- E-mail alarm/event messaging on priority

- Ramp/Soak Setpoint Programmers

- Setpoint Schedulers with multiple outputs

- Sequencers with 16 Outputs each

- Modbus read/write parameters assignable to either fixed or custom addresses for access by HMI or supervisory software

- Modbus TCP Initiator

- Gas flow function blocks per American Gas Association specs (non-Safety configurations only)

- Calendar block for triggering events

- Non-interfering process/safety worksheets capable of handling process and safety configurations

- Built-in Version Control

- Fast updates – 10 ms digital and UIO (900U02-xxxx) 100 ms analog capable Note: Low-Level AI updates @ 0.5 sec.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...