Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

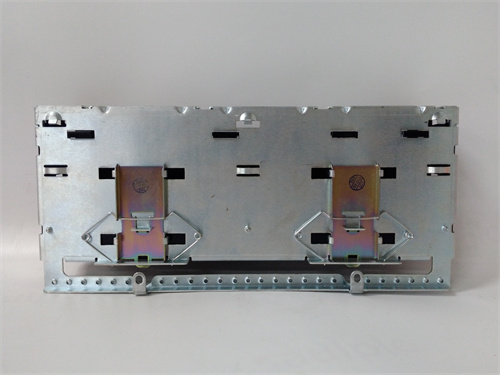

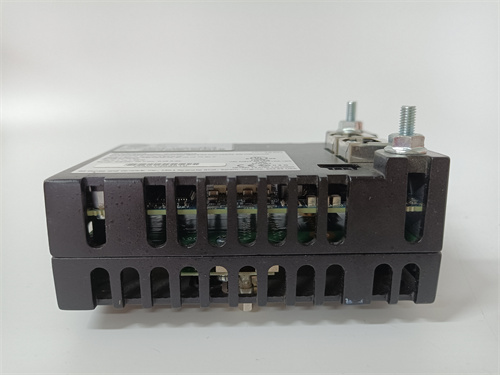

General Electric IS215ACLEH1BC Application Control Layer Module

Manufacturer:GE

Product Number:IS215ACLEH1BC

Product Type:Application Control Layer Module

Origin:USA

Dimensions:147.5 x 95 x 35 mm

Weight:0.8 kg

Views:9

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

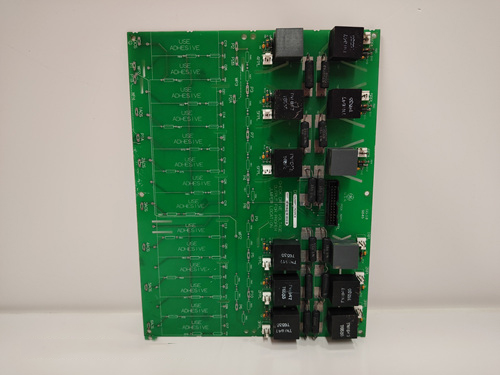

The GE IS215ACLEH1BC Application Control Layer (ACLE) Module is an advanced industrial control module designed for use within GE’s Mark VI and Mark VIe control systems. It serves as a key component in managing application-level processing, communication, and control logic in turbine and industrial automation systems. Built with a robust design, the IS215ACLEH1BC ensures reliable operation under demanding industrial conditions. It integrates advanced processing capabilities and high-speed interfaces to ensure consistent performance for mission-critical operations.

The ACLE module is typically used in power generation plants, oil and gas facilities, and heavy industrial environments where precision, durability, and real-time processing are essential.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | IS215ACLEH1BC |

| Type | Application Control Layer Module |

| Dimensions | 147.5 × 95 × 35 mm |

| Weight | 0.8 kg |

| Processor | High-performance embedded processor |

| Memory | Integrated RAM and non-volatile storage |

| Communication Interfaces | Ethernet, serial, and system bus connectivity |

| Power Supply | 24 VDC (nominal) |

| Operating Temperature | –20 °C to +65 °C |

| Storage Temperature | –40 °C to +85 °C |

| Humidity | 5% to 95% non-condensing |

| Mounting | Rack-mounted with secure retention |

| Compliance | CE, UL, and RoHS certified |

| Diagnostic Functions | Built-in self-test, error logging, and monitoring |

| Firmware | Field-upgradeable for future updates |

Applications

The IS215ACLEH1BC module is highly versatile, supporting a wide range of applications in industrial automation and turbine control systems, including:

Gas and Steam Turbine Control: Provides real-time processing and communication functions for turbine performance optimization.

Power Generation Systems: Ensures stability and precise execution of control commands within generation and distribution equipment.

Industrial Automation: Supports advanced logic execution for manufacturing and process automation applications.

Oil and Gas Facilities: Manages complex control processes and enhances safety mechanisms in high-demand environments.

Retrofit Projects: Compatible with existing Mark VI and Mark VIe architectures for system upgrades.

Research and Development Systems: Ideal for test beds and prototype systems requiring reliable real-time processing.

Advantages

High Processing Power: Delivers robust computation capabilities for handling complex control algorithms efficiently.

Reliable Performance: Built for industrial-grade reliability, ensuring stable operations in mission-critical systems.

Scalable Architecture: Supports expansion and integration with multiple systems in large industrial setups.

Real-Time Communication: Equipped with high-speed Ethernet and serial interfaces for rapid data transfer.

Ease of Maintenance: Modular design allows quick replacement and maintenance without extended downtime.

Long-Term Support: Backed by GE’s extensive support network and spare parts availability.

Enhanced Diagnostic Capabilities: Onboard self-testing and error logging help in proactive maintenance and troubleshooting.

Versatility: Suitable for diverse industrial environments, from power generation to oil and gas operations.

Robust Environmental Tolerance: Designed to withstand extreme temperature, vibration, and humidity conditions.

Future-Proof Design: Supports firmware updates, ensuring adaptability to evolving industrial needs.

FAQ

Q1: What is the primary function of the IS215ACLEH1BC module?

A1: It serves as the control layer for application processing, managing logic execution, and communication in GE Mark VI and Mark VIe systems.

Q2: Is the module compatible with both Mark VI and Mark VIe systems?

A2: Yes, the IS215ACLEH1BC is fully compatible with both systems, making it suitable for system upgrades and expansions.

Q3: How does the module handle system communication?

A3: It uses high-speed Ethernet and serial communication interfaces to ensure real-time data exchange between control layers and field devices.

Q4: What type of diagnostics does this module provide?

A4: It features built-in self-tests, continuous monitoring, and error logging for efficient fault detection and troubleshooting.

Q5: Does the IS215ACLEH1BC support field firmware updates?

A5: Yes, the firmware can be updated in the field, ensuring the module remains up to date with the latest GE system enhancements.

Q6: How does the module ensure system reliability?

A6: With industrial-grade components and robust testing, the module ensures minimal downtime and stable operations under demanding conditions.

Q7: What industries commonly use the IS215ACLEH1BC?

A7: It is widely used in power generation, oil and gas, heavy industrial automation, and research environments requiring precise control.

Q8: Can the module operate in high-temperature environments?

A8: Yes, it is rated for operating temperatures from –20 °C to +65 °C, suitable for most industrial sites.

Q9: What is the power requirement for this module?

A9: The IS215ACLEH1BC operates on a nominal 24 VDC power supply.

Q10: How does this module integrate with existing systems?

A10: It is designed for seamless integration via its rack-mounted design and high-speed communication interfaces, making it ideal for upgrades and retrofits.

General Electric IS215ACLEH1BC Application Control Layer Module

Manufacturer:GE

Product Number:IS215ACLEH1BC

Product Type:Application Control Layer Module

Origin:USA

Dimensions:147.5 x 95 x 35 mm

Weight:0.8 kg

Views:9

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS215ACLEH1BC Application Control Layer (ACLE) Module is an advanced industrial control module designed for use within GE’s Mark VI and Mark VIe control systems. It serves as a key component in managing application-level processing, communication, and control logic in turbine and industrial automation systems. Built with a robust design, the IS215ACLEH1BC ensures reliable operation under demanding industrial conditions. It integrates advanced processing capabilities and high-speed interfaces to ensure consistent performance for mission-critical operations.

The ACLE module is typically used in power generation plants, oil and gas facilities, and heavy industrial environments where precision, durability, and real-time processing are essential.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | IS215ACLEH1BC |

| Type | Application Control Layer Module |

| Dimensions | 147.5 × 95 × 35 mm |

| Weight | 0.8 kg |

| Processor | High-performance embedded processor |

| Memory | Integrated RAM and non-volatile storage |

| Communication Interfaces | Ethernet, serial, and system bus connectivity |

| Power Supply | 24 VDC (nominal) |

| Operating Temperature | –20 °C to +65 °C |

| Storage Temperature | –40 °C to +85 °C |

| Humidity | 5% to 95% non-condensing |

| Mounting | Rack-mounted with secure retention |

| Compliance | CE, UL, and RoHS certified |

| Diagnostic Functions | Built-in self-test, error logging, and monitoring |

| Firmware | Field-upgradeable for future updates |

Applications

The IS215ACLEH1BC module is highly versatile, supporting a wide range of applications in industrial automation and turbine control systems, including:

Gas and Steam Turbine Control: Provides real-time processing and communication functions for turbine performance optimization.

Power Generation Systems: Ensures stability and precise execution of control commands within generation and distribution equipment.

Industrial Automation: Supports advanced logic execution for manufacturing and process automation applications.

Oil and Gas Facilities: Manages complex control processes and enhances safety mechanisms in high-demand environments.

Retrofit Projects: Compatible with existing Mark VI and Mark VIe architectures for system upgrades.

Research and Development Systems: Ideal for test beds and prototype systems requiring reliable real-time processing.

Advantages

High Processing Power: Delivers robust computation capabilities for handling complex control algorithms efficiently.

Reliable Performance: Built for industrial-grade reliability, ensuring stable operations in mission-critical systems.

Scalable Architecture: Supports expansion and integration with multiple systems in large industrial setups.

Real-Time Communication: Equipped with high-speed Ethernet and serial interfaces for rapid data transfer.

Ease of Maintenance: Modular design allows quick replacement and maintenance without extended downtime.

Long-Term Support: Backed by GE’s extensive support network and spare parts availability.

Enhanced Diagnostic Capabilities: Onboard self-testing and error logging help in proactive maintenance and troubleshooting.

Versatility: Suitable for diverse industrial environments, from power generation to oil and gas operations.

Robust Environmental Tolerance: Designed to withstand extreme temperature, vibration, and humidity conditions.

Future-Proof Design: Supports firmware updates, ensuring adaptability to evolving industrial needs.

FAQ

Q1: What is the primary function of the IS215ACLEH1BC module?

A1: It serves as the control layer for application processing, managing logic execution, and communication in GE Mark VI and Mark VIe systems.

Q2: Is the module compatible with both Mark VI and Mark VIe systems?

A2: Yes, the IS215ACLEH1BC is fully compatible with both systems, making it suitable for system upgrades and expansions.

Q3: How does the module handle system communication?

A3: It uses high-speed Ethernet and serial communication interfaces to ensure real-time data exchange between control layers and field devices.

Q4: What type of diagnostics does this module provide?

A4: It features built-in self-tests, continuous monitoring, and error logging for efficient fault detection and troubleshooting.

Q5: Does the IS215ACLEH1BC support field firmware updates?

A5: Yes, the firmware can be updated in the field, ensuring the module remains up to date with the latest GE system enhancements.

Q6: How does the module ensure system reliability?

A6: With industrial-grade components and robust testing, the module ensures minimal downtime and stable operations under demanding conditions.

Q7: What industries commonly use the IS215ACLEH1BC?

A7: It is widely used in power generation, oil and gas, heavy industrial automation, and research environments requiring precise control.

Q8: Can the module operate in high-temperature environments?

A8: Yes, it is rated for operating temperatures from –20 °C to +65 °C, suitable for most industrial sites.

Q9: What is the power requirement for this module?

A9: The IS215ACLEH1BC operates on a nominal 24 VDC power supply.

Q10: How does this module integrate with existing systems?

A10: It is designed for seamless integration via its rack-mounted design and high-speed communication interfaces, making it ideal for upgrades and retrofits.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...