In the high-risk environments of oil & gas exploration, refining, and chemical manufacturing, operational safety is non-negotiable. A reliable Safety Instrumented System (SIS) serves as the last line of defense against process deviations, equipment failures, and potential hazards—protecting personnel, critical assets, and environmental integrity. Our industrial SIS products are specifically engineered to meet the rigorous demands of these sectors, delivering IEC 61511-compliant SIS solutions that combine precision, durability, and seamless integration with existing process control systems. As a trusted provider of Safety Instrumented System products, we prioritize performance and compliance to empower oil & gas and chemical plants with robust safety infrastructure.

Comprehensive SIS Product Range for Critical Industries

We offer a full spectrum of SIS products designed to cover every link in the safety chain, ensuring end-to-end protection for your oil & gas and chemical operations:

1. Safety Sensors & Detectors (Core SIS Components)

Our SIS safety sensors are calibrated to detect abnormal conditions with industry-leading accuracy, serving as the "eyes" of your Safety Instrumented System. Key technical specifications include:

Pressure transmitters: Measuring range -0.1 to 400 bar, accuracy ±0.075% FS, response time <10ms, level of protection IP67/IP68

Gas detectors: Detect flammable (LEL) and toxic gases (H2S, CO, NH3), detection range 0-100% LEL/0-1000 ppm, false alarm rate <0.1%

Temperature switches: Operating temperature -50°C to 600°C, set point accuracy ±1°C, stainless steel 316L housing for corrosion resistance

Flow meters: Compatible with liquid/gas/vapor media, turndown ratio 100:1, pressure rating up to 1000 psi

These SIS products provide real-time data to trigger safety actions, preventing incidents before they escalate—critical for offshore oil rigs and chemical batch processing units.

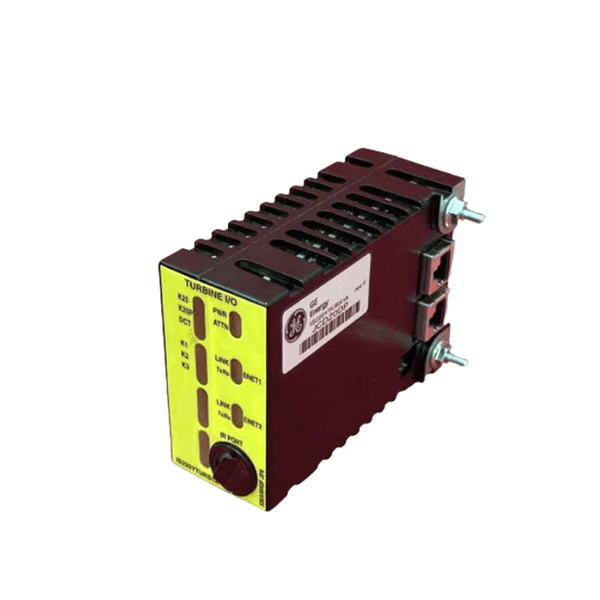

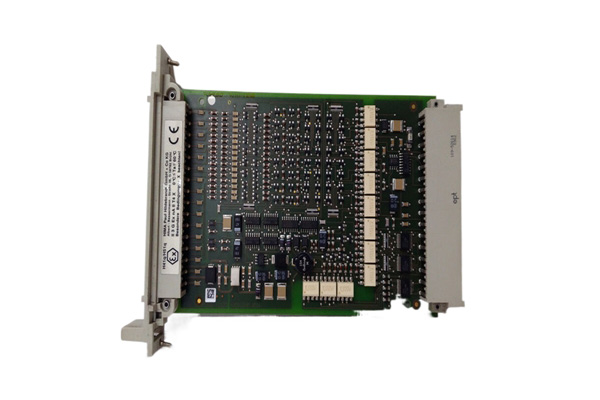

2. Safety Logic Controllers (SLC) – The "Brain" of SIS

As the core of our Safety Instrumented System products, our SLCs process signals from sensors, execute pre-programmed safety interlocks, and initiate corrective measures within milliseconds. Technical highlights:

Safety integrity level (SIL) 3 certification, meeting IEC 61508 standards

Redundant 2oo3 (two-out-of-three) architecture for fault tolerance, ensuring no single point of failure

Processing capacity: Up to 10,000 I/O points, cycle time <1ms per 1000 points

Communication protocols: Compatible with HART, Modbus TCP, PROFIBUS, and OPC UA for seamless integration with DCS/PLC systems

Our SIS logic controllers are deployed in a major Middle Eastern oil refinery, where they reduced unplanned shutdowns by 35% while maintaining 99.99% operational availability.

3. Final Control Elements for SIS

Our SIS final control elements physically implement safety actions dictated by the controller, engineered for reliability in extreme industrial conditions:

Emergency Shutdown (ESD) valves: ANSI Class 150-2500, full port design, actuation time <1 second (fail-safe spring return)

Block valves: Bi-directional flow capability, leak class ANSI VI, compatible with corrosive media (acids, hydrocarbons)

Actuators: Pneumatic/hydraulic/electric options, torque range 50-10,000 Nm, operating temperature -60°C to 180°C

A European chemical plant specializing in polyethylene production upgraded to our SIS ESD valves, which successfully prevented a major monomer leak during a pressure surge—avoiding $2M in potential damages and ensuring zero personnel injuries.

4. Auxiliary SIS Components

Complementing our core SIS products, these components enhance system usability and redundancy:

Safety relays: SIL 2/3 rated, 24VDC/230VAC coil voltage, 8-16 NO/NC contacts

Power supplies: 100-240VAC input, 24VDC output, 5-40A current rating, built-in surge protection

HMIs for SIS: 7-15 inch touchscreens, intrinsic safety certification (ATEX/IECEx), real-time alarm logging and event tracking

Core Advantages of Our Industrial SIS Products

Our SIS product range stands out for its ability to address the unique challenges of oil & gas and chemical industries:

1. Rigorous Compliance & Certification

Every Safety Instrumented System product is designed and tested to meet IEC 61511 (functional safety for process industries) and IEC 61508 (general functional safety) standards. All SIS components carry ATEX, IECEx, and UL certifications, ensuring compliance with regulatory requirements in North America, Europe, the Middle East, and Southeast Asia—eliminating compliance risks for global operations.

2. Industry-Tailored Durability

Constructed with rugged materials (stainless steel 316L, Inconel, PTFE coatings) and sealed enclosures, our SIS products resist moisture, dust, vibration, and chemical exposure. For offshore oil & gas applications, our SIS sensors and valves are rated for saltwater corrosion and extreme pressure (up to 10,000 psi), while chemical plant-specific models withstand corrosive media such as chlorine, ammonia, and sulfuric acid.

3. Seamless Integration with Existing Infrastructure

Our SIS products are compatible with major DCS platforms (Siemens PCS 7, Emerson DeltaV, Honeywell Experion) and PLC systems (Allen-Bradley, Mitsubishi, Omron), ensuring smooth integration without disrupting ongoing operations. A recent project at a Chinese petrochemical plant saw our SIS components integrate with their existing Siemens DCS in just 72 hours, reducing installation downtime by 50% compared to competing SIS products.

4. Scalability & Customization for Unique Needs

Whether you need a compact SIS for a small chemical batch plant or a large-scale system for an offshore oil field, our product range scales to match your requirements. We offer custom SIS configurations, such as explosion-proof enclosures for hazardous areas (Zone 1/2 for gas, Zone 21/22 for dust) and low-power models for remote oil & gas facilities with limited power supply.

Partner with Us for Reliable SIS Products

In oil & gas, where a single equipment failure can lead to catastrophic leaks or explosions, and in chemical manufacturing, where toxic or flammable substances are handled daily, our SIS products provide the reliability and performance you need to safeguard your operations. From upstream exploration to downstream refining, and from batch processing to continuous production lines, our Safety Instrumented System products have been deployed in over 5,000 facilities across 40+ countries, earning the trust of industry leaders including Shell, BASF, and Sinopec.

We understand that safety is not just a compliance requirement but a business imperative. Our SIS products are backed by comprehensive technical support, including free product Selection consultation,on-site installation guidance, and 24/7 global after-sales service. We also offer calibration and maintenance training for your team to ensure your Safety Instrumented System operates at peak performance throughout its lifecycle.

Choose our industrial SIS products to strengthen your safety infrastructure, protect your workforce and assets, and maintain uninterrupted operations—all while meeting global functional safety standards. Contact our team today to request detailed product datasheets, custom SIS solution proposals, or references from our oil & gas and chemical industry clients.