Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

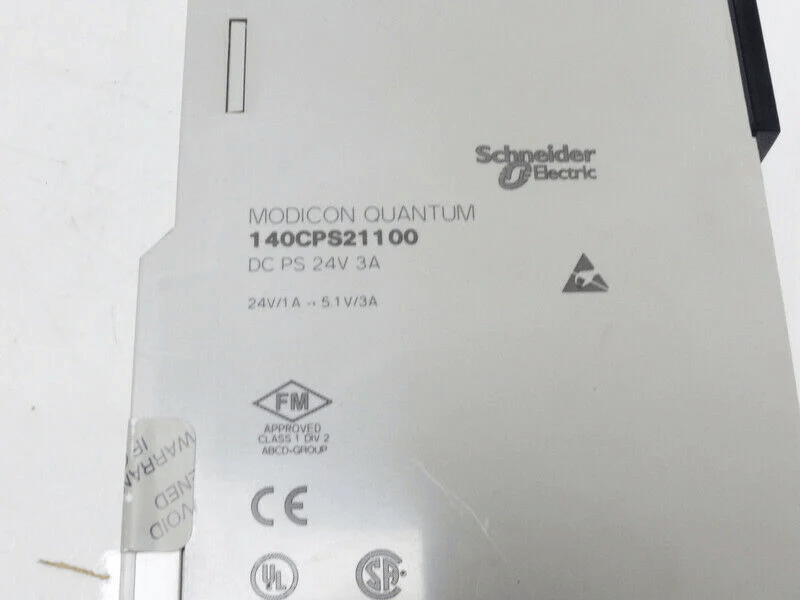

Schneider STBACI0320K Standard Analog Input Module

Manufacturer:Schneider

Product Number:STBACI0320K

Product Type:Standard Analog Input Module

Origin:France

Dimensions:70 x 18.4 x 128.3 mm

Weight:0.099 kg

Views:37

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider Electric STBACI0320K is a Standard Analog Input Module designed as part of the Advantys STB distributed I/O system. It provides analog input capabilities for decentralized control architectures, making it suitable for demanding automation tasks in manufacturing, energy, and infrastructure sectors.

This module is capable of processing 4 analog current inputs in the range of 4–20 mA, allowing it to interface with various field devices such as sensors, transducers, and instrumentation. Engineered for high-precision signal acquisition, the STBACI0320K ensures reliable data conversion and transmission to host controllers via fieldbus networks like Modbus, Ethernet, or PROFIBUS through the STB island bus system.

Built for compact, scalable, and cost-efficient applications, this module is ideal for OEMs and system integrators who require flexibility without sacrificing performance.

Product Specifications

| Parameter | Details |

|---|---|

| Manufacturer | Schneider Electric |

| Product Series | Advantys STB |

| Model Number | STBACI0320K |

| Module Type | Analog Input Module |

| Number of Channels | 4 analog input channels |

| Input Signal Type | Current input (4–20 mA) |

| Input Resolution | 12-bit |

| Conversion Time | 4 ms per channel |

| Accuracy | ±0.5% of full-scale |

| Isolation | 500 V RMS channel-to-bus and channel-to-channel |

| Bus Interface | STB island bus (connected via network interface module) |

| Diagnostics | Channel diagnostics via status LEDs |

| Power Consumption | <1.2 W |

| Mounting Type | DIN rail (35 mm) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% non-condensing |

| Compliance Certifications | CE, UL, CSA, RoHS |

| Dimensions (H × W × D) | 70 x 18.4 x 128.3 mm |

| Weight | 0.099 kg |

Applications

The STBACI0320K module is used extensively in distributed automation environments where space-saving and modularity are essential. Common application domains include:

Process Control: Interface with pressure transmitters, flow meters, and level sensors in chemical and food industries.

Building Management Systems: Monitor environmental parameters such as temperature and humidity.

Energy Monitoring: Collect analog data from electrical transducers or energy meters.

Water Treatment Plants: Integrate with pH sensors, turbidity sensors, and pump monitoring systems.

OEM Machinery: Implement scalable analog input capabilities in packaged machines or equipment skids.

Renewable Energy Systems: Gather performance data from solar inverters, wind sensors, or battery banks.

Product Advantages

Compact Footprint: Saves valuable space in control cabinets, ideal for modular designs.

High Accuracy: ±0.5% accuracy ensures precise analog signal processing.

Easy Integration: Seamless connection within the STB island bus system for fast deployment.

Multi-Channel Efficiency: Four inputs in a single module reduce the need for additional hardware.

Field Diagnostics: Built-in status LEDs simplify troubleshooting.

Scalable Architecture: Easily expandable for future growth without reworking existing wiring.

Frequently Asked Questions (FAQ)

Q: What input signals does the STBACI0320K support?

A: It supports 4–20 mA current loop signals, commonly used in industrial analog instrumentation.

Q: Can the module handle different analog ranges on each channel?

A: No, all channels are configured for the 4–20 mA range. Mixing voltage and current on this module is not supported.

Q: How are the analog channels isolated?

A: Each channel is optically isolated from others and from the STB bus, with isolation up to 500 V RMS.

Q: Is calibration required after installation?

A: The module comes factory-calibrated. Recalibration is not typically necessary unless required by your QA standards.

Q: How does it communicate with a PLC or host controller?

A: Through the STB island bus and a network interface module (e.g., STBNIP2311 for Ethernet).

Q: What is the recommended wiring for field devices?

A: Use shielded twisted-pair cables to reduce noise and ensure accurate analog readings.

Q: What happens if an input signal exceeds 20 mA?

A: The module includes over-range detection and diagnostics. It won’t be damaged by minor overcurrents but will indicate a fault.

Q: Can I mix this module with digital I/O on the same island?

A: Yes, the STB system supports mixed module configurations, including analog, digital, and specialty modules.

Q: Is hot-swapping supported?

A: Yes, you can replace the module while the system is powered, provided the network interface supports it.

Q: What are the benefits over traditional rack-mounted I/O?

A: It offers modular flexibility, space-saving installation, reduced wiring, and faster maintenance in distributed control systems.

Schneider STBACI0320K Standard Analog Input Module

Manufacturer:Schneider

Product Number:STBACI0320K

Product Type:Standard Analog Input Module

Origin:France

Dimensions:70 x 18.4 x 128.3 mm

Weight:0.099 kg

Views:37

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider Electric STBACI0320K is a Standard Analog Input Module designed as part of the Advantys STB distributed I/O system. It provides analog input capabilities for decentralized control architectures, making it suitable for demanding automation tasks in manufacturing, energy, and infrastructure sectors.

This module is capable of processing 4 analog current inputs in the range of 4–20 mA, allowing it to interface with various field devices such as sensors, transducers, and instrumentation. Engineered for high-precision signal acquisition, the STBACI0320K ensures reliable data conversion and transmission to host controllers via fieldbus networks like Modbus, Ethernet, or PROFIBUS through the STB island bus system.

Built for compact, scalable, and cost-efficient applications, this module is ideal for OEMs and system integrators who require flexibility without sacrificing performance.

Product Specifications

| Parameter | Details |

|---|---|

| Manufacturer | Schneider Electric |

| Product Series | Advantys STB |

| Model Number | STBACI0320K |

| Module Type | Analog Input Module |

| Number of Channels | 4 analog input channels |

| Input Signal Type | Current input (4–20 mA) |

| Input Resolution | 12-bit |

| Conversion Time | 4 ms per channel |

| Accuracy | ±0.5% of full-scale |

| Isolation | 500 V RMS channel-to-bus and channel-to-channel |

| Bus Interface | STB island bus (connected via network interface module) |

| Diagnostics | Channel diagnostics via status LEDs |

| Power Consumption | <1.2 W |

| Mounting Type | DIN rail (35 mm) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% non-condensing |

| Compliance Certifications | CE, UL, CSA, RoHS |

| Dimensions (H × W × D) | 70 x 18.4 x 128.3 mm |

| Weight | 0.099 kg |

Applications

The STBACI0320K module is used extensively in distributed automation environments where space-saving and modularity are essential. Common application domains include:

Process Control: Interface with pressure transmitters, flow meters, and level sensors in chemical and food industries.

Building Management Systems: Monitor environmental parameters such as temperature and humidity.

Energy Monitoring: Collect analog data from electrical transducers or energy meters.

Water Treatment Plants: Integrate with pH sensors, turbidity sensors, and pump monitoring systems.

OEM Machinery: Implement scalable analog input capabilities in packaged machines or equipment skids.

Renewable Energy Systems: Gather performance data from solar inverters, wind sensors, or battery banks.

Product Advantages

Compact Footprint: Saves valuable space in control cabinets, ideal for modular designs.

High Accuracy: ±0.5% accuracy ensures precise analog signal processing.

Easy Integration: Seamless connection within the STB island bus system for fast deployment.

Multi-Channel Efficiency: Four inputs in a single module reduce the need for additional hardware.

Field Diagnostics: Built-in status LEDs simplify troubleshooting.

Scalable Architecture: Easily expandable for future growth without reworking existing wiring.

Frequently Asked Questions (FAQ)

Q: What input signals does the STBACI0320K support?

A: It supports 4–20 mA current loop signals, commonly used in industrial analog instrumentation.

Q: Can the module handle different analog ranges on each channel?

A: No, all channels are configured for the 4–20 mA range. Mixing voltage and current on this module is not supported.

Q: How are the analog channels isolated?

A: Each channel is optically isolated from others and from the STB bus, with isolation up to 500 V RMS.

Q: Is calibration required after installation?

A: The module comes factory-calibrated. Recalibration is not typically necessary unless required by your QA standards.

Q: How does it communicate with a PLC or host controller?

A: Through the STB island bus and a network interface module (e.g., STBNIP2311 for Ethernet).

Q: What is the recommended wiring for field devices?

A: Use shielded twisted-pair cables to reduce noise and ensure accurate analog readings.

Q: What happens if an input signal exceeds 20 mA?

A: The module includes over-range detection and diagnostics. It won’t be damaged by minor overcurrents but will indicate a fault.

Q: Can I mix this module with digital I/O on the same island?

A: Yes, the STB system supports mixed module configurations, including analog, digital, and specialty modules.

Q: Is hot-swapping supported?

A: Yes, you can replace the module while the system is powered, provided the network interface supports it.

Q: What are the benefits over traditional rack-mounted I/O?

A: It offers modular flexibility, space-saving installation, reduced wiring, and faster maintenance in distributed control systems.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...