Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

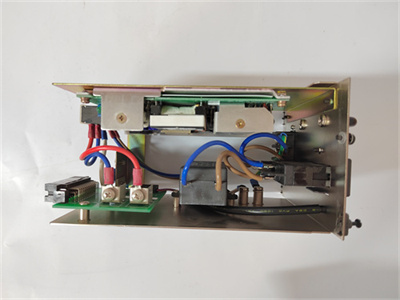

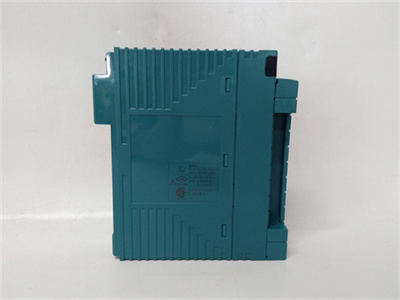

Yokogawa NFAI143 Analog Input Module

Manufacturer:Yokogawa

Product Number:NFAI143

Product Type:Analog Input Module

Origin:Japan

Dimensions:130 x 107.5 x 32.8 mm

Weight:0.3 kg

Views:47

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa NFAI143 is a high-integrity Analog Input Module developed for use in ProSafe-RS safety instrumented systems (SIS). It serves as a critical input component in safety control systems, acquiring analog signals from field instruments such as transmitters and sensors and delivering accurate, fault-monitored input data to the Safety Control Station (SCS).

Designed to meet the strict safety, performance, and environmental requirements of modern industrial automation, the NFAI143 provides high-resolution signal conversion, robust input isolation, and full diagnostic capabilities. It is particularly well-suited for applications where Safety Integrity Level (SIL3) compliance is required, such as emergency shutdown (ESD), fire and gas systems, and other critical safety loops.

The module integrates seamlessly into Yokogawa’s ProSafe-RS architecture, supporting efficient engineering, maintenance, and lifecycle management while ensuring maximum operational uptime in hazardous environments.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | NFAI143 |

| Function | Analog Input Module for Safety Instrumented System (SIS) |

| System Compatibility | ProSafe-RS |

| Number of Channels | 16 analog inputs |

| Input Signal Range | 4–20 mA DC (standard), configurable for other ranges |

| Input Type | Single-ended |

| Input Impedance | ≥250 Ω |

| A/D Conversion Resolution | 16-bit |

| Channel Isolation | Channel-to-channel and channel-to-bus isolation |

| Signal Accuracy | ±0.1% of span |

| Update Cycle | 100 ms (typical) |

| Built-in Diagnostics | Open circuit detection, over-range/under-range detection |

| Redundancy Support | Yes (SCS redundant configurations supported) |

| Self-Testing Capability | Yes, with automatic loop check |

| Operating Temperature | 0 to 55°C |

| Storage Temperature | -20 to 70°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Mounting Method | Mounted on SCS baseplate |

| Module Material | Flame-retardant industrial-grade resin |

| Power Supply | Via SCS base (no external supply required) |

| Dimensions (W × H × D) | 130 x 107.5 x 32.8 mm |

| Weight | 0.3 kg |

| Certifications | SIL3 (IEC 61508), CE, RoHS, ATEX, CSA, UL |

Applications

The NFAI143 Analog Input Module is purpose-built for industrial safety-critical environments requiring precise and fail-safe signal acquisition. It is widely deployed in the following sectors:

Oil & Gas Facilities – For pressure, level, and flow monitoring in emergency shutdown systems.

Chemical Processing Plants – Interfaces analog transmitters for safety relief, burner management, and toxic gas detection.

Power Generation Plants – Supports high-reliability monitoring of steam boilers, turbines, and water chemistry systems.

LNG Terminals and Pipelines – Collects and supervises cryogenic sensor signals under strict safety protocols.

Water and Wastewater Treatment – Ensures safe process control in chlorine dosing and sludge handling.

Pharmaceutical Manufacturing – Monitors critical batch conditions within validated safety control frameworks.

Product Advantages

SIL3-Certified Safety: Meets international safety standards (IEC 61508), ensuring reliability in high-risk control systems.

Robust Signal Handling: Supports 16-bit high-resolution conversion for precise analog measurements.

Advanced Diagnostics: Real-time detection of open circuits, over-range signals, and hardware faults.

Compact Form Factor: Slim module width allows for high-density installations in SCS enclosures.

Modular Integration: Seamlessly fits into ProSafe-RS architecture, reducing engineering effort.

Channel Isolation: Prevents crosstalk and fault propagation between input channels.

Auto Calibration and Testing: Built-in self-testing features streamline commissioning and preventive maintenance.

Redundancy Capable: Fully supports dual redundant configurations for maximum uptime.

Environmentally Durable: Performs reliably in industrial environments with wide temperature and humidity tolerances.

Vendor Support: Backed by Yokogawa’s long-term lifecycle support and international field service network.

Frequently Asked Questions (FAQ)

What type of analog signals can the NFAI143 accept?

The module supports 4–20 mA DC analog signals, which are standard for most industrial transmitters and sensors.

Is the NFAI143 compliant with SIL3 standards?

Yes, it is certified to SIL3 under IEC 61508, making it suitable for safety-critical loops.

Can I use the NFAI143 in a redundant configuration?

Absolutely. It works seamlessly with SCS redundancy setups within the ProSafe-RS system.

Does the module provide diagnostics on its inputs?

Yes, it features open circuit detection, over-range checks, and other signal integrity diagnostics.

How does the NFAI143 integrate into ProSafe-RS systems?

It is installed directly into the SCS baseplate, where it communicates with the CPU over the system backplane.

Is it possible to perform loop checks automatically?

Yes, the module supports automatic loop checking during commissioning or system tests.

What is the input update cycle of this module?

The typical input scan time is around 100 ms, which is well within the range for safety response.

Does it support isolated input channels?

Yes, each channel is electrically isolated from others and the system bus for safety and reliability.

How is configuration handled for this module?

Configuration is done via Yokogawa’s engineering tools like SENG and SCS Configurator.

What happens if one of the channels fails?

The module’s internal diagnostics will detect the failure and alert the system, allowing safe fallback or failover operations based on your SIS configuration.

Yokogawa NFAI143 Analog Input Module

Manufacturer:Yokogawa

Product Number:NFAI143

Product Type:Analog Input Module

Origin:Japan

Dimensions:130 x 107.5 x 32.8 mm

Weight:0.3 kg

Views:47

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa NFAI143 is a high-integrity Analog Input Module developed for use in ProSafe-RS safety instrumented systems (SIS). It serves as a critical input component in safety control systems, acquiring analog signals from field instruments such as transmitters and sensors and delivering accurate, fault-monitored input data to the Safety Control Station (SCS).

Designed to meet the strict safety, performance, and environmental requirements of modern industrial automation, the NFAI143 provides high-resolution signal conversion, robust input isolation, and full diagnostic capabilities. It is particularly well-suited for applications where Safety Integrity Level (SIL3) compliance is required, such as emergency shutdown (ESD), fire and gas systems, and other critical safety loops.

The module integrates seamlessly into Yokogawa’s ProSafe-RS architecture, supporting efficient engineering, maintenance, and lifecycle management while ensuring maximum operational uptime in hazardous environments.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | NFAI143 |

| Function | Analog Input Module for Safety Instrumented System (SIS) |

| System Compatibility | ProSafe-RS |

| Number of Channels | 16 analog inputs |

| Input Signal Range | 4–20 mA DC (standard), configurable for other ranges |

| Input Type | Single-ended |

| Input Impedance | ≥250 Ω |

| A/D Conversion Resolution | 16-bit |

| Channel Isolation | Channel-to-channel and channel-to-bus isolation |

| Signal Accuracy | ±0.1% of span |

| Update Cycle | 100 ms (typical) |

| Built-in Diagnostics | Open circuit detection, over-range/under-range detection |

| Redundancy Support | Yes (SCS redundant configurations supported) |

| Self-Testing Capability | Yes, with automatic loop check |

| Operating Temperature | 0 to 55°C |

| Storage Temperature | -20 to 70°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Mounting Method | Mounted on SCS baseplate |

| Module Material | Flame-retardant industrial-grade resin |

| Power Supply | Via SCS base (no external supply required) |

| Dimensions (W × H × D) | 130 x 107.5 x 32.8 mm |

| Weight | 0.3 kg |

| Certifications | SIL3 (IEC 61508), CE, RoHS, ATEX, CSA, UL |

Applications

The NFAI143 Analog Input Module is purpose-built for industrial safety-critical environments requiring precise and fail-safe signal acquisition. It is widely deployed in the following sectors:

Oil & Gas Facilities – For pressure, level, and flow monitoring in emergency shutdown systems.

Chemical Processing Plants – Interfaces analog transmitters for safety relief, burner management, and toxic gas detection.

Power Generation Plants – Supports high-reliability monitoring of steam boilers, turbines, and water chemistry systems.

LNG Terminals and Pipelines – Collects and supervises cryogenic sensor signals under strict safety protocols.

Water and Wastewater Treatment – Ensures safe process control in chlorine dosing and sludge handling.

Pharmaceutical Manufacturing – Monitors critical batch conditions within validated safety control frameworks.

Product Advantages

SIL3-Certified Safety: Meets international safety standards (IEC 61508), ensuring reliability in high-risk control systems.

Robust Signal Handling: Supports 16-bit high-resolution conversion for precise analog measurements.

Advanced Diagnostics: Real-time detection of open circuits, over-range signals, and hardware faults.

Compact Form Factor: Slim module width allows for high-density installations in SCS enclosures.

Modular Integration: Seamlessly fits into ProSafe-RS architecture, reducing engineering effort.

Channel Isolation: Prevents crosstalk and fault propagation between input channels.

Auto Calibration and Testing: Built-in self-testing features streamline commissioning and preventive maintenance.

Redundancy Capable: Fully supports dual redundant configurations for maximum uptime.

Environmentally Durable: Performs reliably in industrial environments with wide temperature and humidity tolerances.

Vendor Support: Backed by Yokogawa’s long-term lifecycle support and international field service network.

Frequently Asked Questions (FAQ)

What type of analog signals can the NFAI143 accept?

The module supports 4–20 mA DC analog signals, which are standard for most industrial transmitters and sensors.

Is the NFAI143 compliant with SIL3 standards?

Yes, it is certified to SIL3 under IEC 61508, making it suitable for safety-critical loops.

Can I use the NFAI143 in a redundant configuration?

Absolutely. It works seamlessly with SCS redundancy setups within the ProSafe-RS system.

Does the module provide diagnostics on its inputs?

Yes, it features open circuit detection, over-range checks, and other signal integrity diagnostics.

How does the NFAI143 integrate into ProSafe-RS systems?

It is installed directly into the SCS baseplate, where it communicates with the CPU over the system backplane.

Is it possible to perform loop checks automatically?

Yes, the module supports automatic loop checking during commissioning or system tests.

What is the input update cycle of this module?

The typical input scan time is around 100 ms, which is well within the range for safety response.

Does it support isolated input channels?

Yes, each channel is electrically isolated from others and the system bus for safety and reliability.

How is configuration handled for this module?

Configuration is done via Yokogawa’s engineering tools like SENG and SCS Configurator.

What happens if one of the channels fails?

The module’s internal diagnostics will detect the failure and alert the system, allowing safe fallback or failover operations based on your SIS configuration.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...