Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

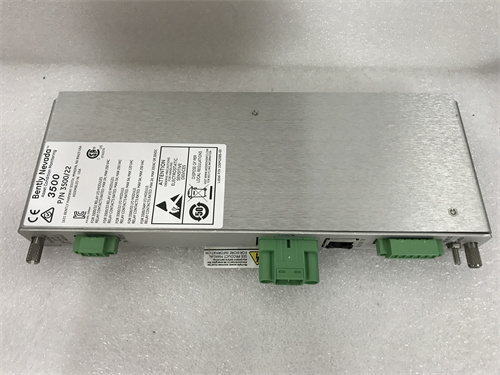

Bently Nevada 330171-00-10-05-11-05 3300 5mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330171-00-10-05-11-05

Product Type:3300 5mm Proximity Probe

Origin:USA

Total Length:0.5 meter

Weight:0.161kg

Views:35

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330171-00-10-05-11-05 3300 5mm Proximity Probe is a highly precise industrial sensor used to measure displacement, vibration, and alignment of rotating machinery components. This sensor is part of the well-established 3300 series by Bently Nevada, known for its exceptional accuracy and robustness in monitoring the condition of critical machinery. The 3300 series probes are designed for use in industries where precise measurements and reliability are paramount.

This 5mm proximity probe is particularly well-suited for applications where tight installation spaces and compact dimensions are required. Its high sensitivity allows for accurate monitoring of shaft displacement and vibrations, which are critical indicators of machinery health. Early detection of faults such as misalignment, imbalance, or wear can significantly reduce the risk of catastrophic equipment failure and minimize unplanned downtime.

The 3300 5mm Proximity Probe is ideal for a variety of industrial applications, including turbines, compressors, motors, pumps, and general rotating equipment. The rugged design and high-quality materials ensure that the probe can withstand harsh industrial environments, including extreme temperatures, vibrations, and mechanical shocks.

Product Parameters

| Parameter | Value |

|---|---|

| Total Length | 0.5 meter |

| Weight | 0.161 kg |

| Sensing Range | 5 mm |

| Power Supply | 18-30 V DC |

| Vibration Resistance | 50 g (20 to 2000 Hz) |

| Shock Resistance | 100 g (1 ms) |

| Operating Temperature | -40°C to +85°C |

| Mounting Type | Threaded or Bolt-On |

| Output Signal | 4-20 mA (Analog) |

| Frequency Response | 0 to 50 kHz |

Product Applications

The Bently Nevada 330171-00-10-05-11-05 3300 5mm Proximity Probe is widely utilized in various industrial sectors that rely on precise measurements of rotating machinery. Some of its key applications include:

Turbine Monitoring: The probe is essential for monitoring the displacement of turbine shafts, helping detect misalignments or vibrations that could lead to catastrophic failures.

Compressor Monitoring: It helps track the position and displacement of compressor shafts, ensuring they operate smoothly and preventing damage due to misalignment or imbalance.

Electric Motor Monitoring: The probe is used to measure shaft displacement and vibration in electric motors, allowing for early detection of faults and enhancing motor efficiency and performance.

Pump Systems: The proximity probe is crucial in monitoring the condition of pump shafts, detecting misalignment, displacement, or other issues that can affect performance.

Conveyor Systems: In conveyor systems, the probe helps measure the displacement and alignment of shafts, ensuring continuous operation and minimizing unplanned interruptions.

General Rotating Equipment: The 3300 5mm Proximity Probe is suitable for various rotating machinery, including fans, mixers, and blowers, where precise displacement and vibration monitoring is necessary.

Advantages of the Product

High Precision: The 3300 5mm Proximity Probe offers highly accurate measurements of shaft displacement, allowing for the early detection of misalignments, imbalances, and other issues in rotating machinery.

Compact Design: With a sensing range of 5mm and a total length of 0.5 meter, this probe is ideal for installations where space is limited, ensuring it fits in tight or confined areas.

Durability: Built to withstand harsh industrial environments, the probe is resistant to high levels of vibration (up to 50 g) and shock (up to 100 g). It also operates in temperatures ranging from -40°C to +85°C, making it suitable for extreme conditions.

Predictive Maintenance: By providing early warning signs of issues like misalignment or vibration, the probe enables predictive maintenance, preventing catastrophic failures and reducing downtime.

Easy Integration: The 4-20 mA analog output makes the probe easily integrable into existing condition monitoring systems, providing real-time data on machinery health.

Long Operational Life: The high-quality materials and rugged design ensure the probe performs reliably over a long period with minimal maintenance requirements.

Wide Frequency Response: The probe offers a frequency response of up to 50 kHz, enabling it to capture high-frequency vibrations and displacement data for more detailed analysis.

Safety Enhancement: By detecting mechanical problems before they cause significant damage, the probe helps to ensure a safer working environment by minimizing the risk of machinery failure.

Flexible Mounting Options: The probe can be mounted using either threaded or bolt-on methods, making installation easy and adaptable to different machinery types.

Proven Reliability: As part of the Bently Nevada 3300 series, the probe benefits from the brand’s long-standing reputation for delivering accurate, durable, and reliable products for machinery condition monitoring.

FAQs

What is the sensing range of the 3300 5mm Proximity Probe?

-

The 3300 5mm Proximity Probe has a sensing range of 5 mm, providing precise measurements for small displacements in rotating machinery.

-

What is the total length of the Bently Nevada 3300 5mm Proximity Probe?

-

The total length of the probe is 0.5 meter, making it compact and ideal for installations in tight spaces.

-

What type of power supply does the 3300 5mm Proximity Probe require?

-

The probe operates with a DC power supply of 18-30 V.

-

How does the 3300 5mm Proximity Probe help with predictive maintenance?

-

By continuously monitoring displacement and vibration, the probe detects potential issues such as misalignment or imbalance early, reducing the likelihood of unplanned breakdowns.

-

What is the vibration resistance of the Bently Nevada 3300 5mm Proximity Probe?

-

The probe can withstand vibration levels up to 50 g in the frequency range of 20 to 2000 Hz, ensuring it remains operational in high-vibration environments.

-

How shock-resistant is the 3300 5mm Proximity Probe?

-

The probe can resist shocks up to 100 g (1 ms), making it highly durable and reliable in environments prone to mechanical shocks.

-

What output signal does the 3300 5mm Proximity Probe provide?

-

The probe outputs a 4-20 mA analog signal, which can be easily integrated into existing machinery monitoring systems for real-time data acquisition.

-

What is the temperature range in which the 3300 5mm Proximity Probe operates?

-

The probe operates in temperatures ranging from -40°C to +85°C, making it suitable for use in a wide range of industrial environments.

-

Which industries benefit from using the 3300 5mm Proximity Probe?

-

Industries such as power generation, oil and gas, manufacturing, petrochemical, and others benefit from the probe’s precision in monitoring rotating machinery.

-

How easy is it to integrate the 3300 5mm Proximity Probe into existing systems?

-

The 3300 5mm Proximity Probe is designed to integrate easily into most existing monitoring systems due to its 4-20 mA analog output signal, providing real-time data on machinery health.

-

Bently Nevada 330171-00-10-05-11-05 3300 5mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330171-00-10-05-11-05

Product Type:3300 5mm Proximity Probe

Origin:USA

Total Length:0.5 meter

Weight:0.161kg

Views:35

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330171-00-10-05-11-05 3300 5mm Proximity Probe is a highly precise industrial sensor used to measure displacement, vibration, and alignment of rotating machinery components. This sensor is part of the well-established 3300 series by Bently Nevada, known for its exceptional accuracy and robustness in monitoring the condition of critical machinery. The 3300 series probes are designed for use in industries where precise measurements and reliability are paramount.

This 5mm proximity probe is particularly well-suited for applications where tight installation spaces and compact dimensions are required. Its high sensitivity allows for accurate monitoring of shaft displacement and vibrations, which are critical indicators of machinery health. Early detection of faults such as misalignment, imbalance, or wear can significantly reduce the risk of catastrophic equipment failure and minimize unplanned downtime.

The 3300 5mm Proximity Probe is ideal for a variety of industrial applications, including turbines, compressors, motors, pumps, and general rotating equipment. The rugged design and high-quality materials ensure that the probe can withstand harsh industrial environments, including extreme temperatures, vibrations, and mechanical shocks.

Product Parameters

| Parameter | Value |

|---|---|

| Total Length | 0.5 meter |

| Weight | 0.161 kg |

| Sensing Range | 5 mm |

| Power Supply | 18-30 V DC |

| Vibration Resistance | 50 g (20 to 2000 Hz) |

| Shock Resistance | 100 g (1 ms) |

| Operating Temperature | -40°C to +85°C |

| Mounting Type | Threaded or Bolt-On |

| Output Signal | 4-20 mA (Analog) |

| Frequency Response | 0 to 50 kHz |

Product Applications

The Bently Nevada 330171-00-10-05-11-05 3300 5mm Proximity Probe is widely utilized in various industrial sectors that rely on precise measurements of rotating machinery. Some of its key applications include:

Turbine Monitoring: The probe is essential for monitoring the displacement of turbine shafts, helping detect misalignments or vibrations that could lead to catastrophic failures.

Compressor Monitoring: It helps track the position and displacement of compressor shafts, ensuring they operate smoothly and preventing damage due to misalignment or imbalance.

Electric Motor Monitoring: The probe is used to measure shaft displacement and vibration in electric motors, allowing for early detection of faults and enhancing motor efficiency and performance.

Pump Systems: The proximity probe is crucial in monitoring the condition of pump shafts, detecting misalignment, displacement, or other issues that can affect performance.

Conveyor Systems: In conveyor systems, the probe helps measure the displacement and alignment of shafts, ensuring continuous operation and minimizing unplanned interruptions.

General Rotating Equipment: The 3300 5mm Proximity Probe is suitable for various rotating machinery, including fans, mixers, and blowers, where precise displacement and vibration monitoring is necessary.

Advantages of the Product

High Precision: The 3300 5mm Proximity Probe offers highly accurate measurements of shaft displacement, allowing for the early detection of misalignments, imbalances, and other issues in rotating machinery.

Compact Design: With a sensing range of 5mm and a total length of 0.5 meter, this probe is ideal for installations where space is limited, ensuring it fits in tight or confined areas.

Durability: Built to withstand harsh industrial environments, the probe is resistant to high levels of vibration (up to 50 g) and shock (up to 100 g). It also operates in temperatures ranging from -40°C to +85°C, making it suitable for extreme conditions.

Predictive Maintenance: By providing early warning signs of issues like misalignment or vibration, the probe enables predictive maintenance, preventing catastrophic failures and reducing downtime.

Easy Integration: The 4-20 mA analog output makes the probe easily integrable into existing condition monitoring systems, providing real-time data on machinery health.

Long Operational Life: The high-quality materials and rugged design ensure the probe performs reliably over a long period with minimal maintenance requirements.

Wide Frequency Response: The probe offers a frequency response of up to 50 kHz, enabling it to capture high-frequency vibrations and displacement data for more detailed analysis.

Safety Enhancement: By detecting mechanical problems before they cause significant damage, the probe helps to ensure a safer working environment by minimizing the risk of machinery failure.

Flexible Mounting Options: The probe can be mounted using either threaded or bolt-on methods, making installation easy and adaptable to different machinery types.

Proven Reliability: As part of the Bently Nevada 3300 series, the probe benefits from the brand’s long-standing reputation for delivering accurate, durable, and reliable products for machinery condition monitoring.

FAQs

What is the sensing range of the 3300 5mm Proximity Probe?

-

The 3300 5mm Proximity Probe has a sensing range of 5 mm, providing precise measurements for small displacements in rotating machinery.

-

What is the total length of the Bently Nevada 3300 5mm Proximity Probe?

-

The total length of the probe is 0.5 meter, making it compact and ideal for installations in tight spaces.

-

What type of power supply does the 3300 5mm Proximity Probe require?

-

The probe operates with a DC power supply of 18-30 V.

-

How does the 3300 5mm Proximity Probe help with predictive maintenance?

-

By continuously monitoring displacement and vibration, the probe detects potential issues such as misalignment or imbalance early, reducing the likelihood of unplanned breakdowns.

-

What is the vibration resistance of the Bently Nevada 3300 5mm Proximity Probe?

-

The probe can withstand vibration levels up to 50 g in the frequency range of 20 to 2000 Hz, ensuring it remains operational in high-vibration environments.

-

How shock-resistant is the 3300 5mm Proximity Probe?

-

The probe can resist shocks up to 100 g (1 ms), making it highly durable and reliable in environments prone to mechanical shocks.

-

What output signal does the 3300 5mm Proximity Probe provide?

-

The probe outputs a 4-20 mA analog signal, which can be easily integrated into existing machinery monitoring systems for real-time data acquisition.

-

What is the temperature range in which the 3300 5mm Proximity Probe operates?

-

The probe operates in temperatures ranging from -40°C to +85°C, making it suitable for use in a wide range of industrial environments.

-

Which industries benefit from using the 3300 5mm Proximity Probe?

-

Industries such as power generation, oil and gas, manufacturing, petrochemical, and others benefit from the probe’s precision in monitoring rotating machinery.

-

How easy is it to integrate the 3300 5mm Proximity Probe into existing systems?

-

The 3300 5mm Proximity Probe is designed to integrate easily into most existing monitoring systems due to its 4-20 mA analog output signal, providing real-time data on machinery health.

-

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...