Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

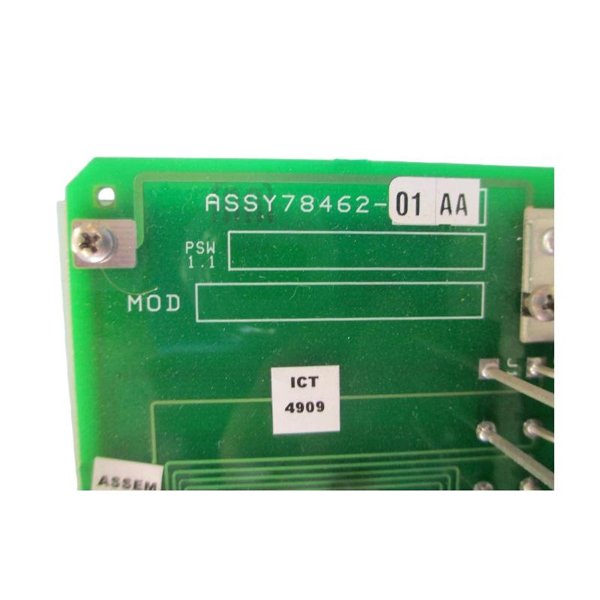

Bently Nevada 84145-01 XDUCR I/O and Recording Terminal

Manufacturer:Bently Nevada

Product Number:84145-01

Product Type:XDUCR I/O and Recording Terminal

Origin:USA

Dimensions:51x 102x 229mm

Weight:0.35 kg

Views:23

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

With robust design and reliable performance, the 84145-01 helps ensure the safety, efficiency, and longevity of expensive machinery assets by providing precise, real-time data about shaft position and dynamic vibration. Its compact design allows for easier installation in tight spaces without sacrificing measurement accuracy.

Product Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 84145-01 |

| Measurement Range | 0 to 2 mm (0 to 80 mils) |

| Sensitivity | 7.87 mV/μm (200 mV/mil) |

| Dimension | 51x 102x 229mm |

| Weight | 0.35 kg |

| Operating Temperature | –35 °C to +175 °C (–31 °F to +347 °F) |

| Storage Temperature | –40 °C to +200 °C (–40 °F to +392 °F) |

| Output Signal | Voltage proportional to target displacement |

| Power Supply | ±15 VDC from monitoring system |

| Housing Material | Stainless steel |

| Insulation Resistance | > 100 MΩ at 500 VDC |

Product Applications

The Bently Nevada 84145-01 is widely used in:

-

Large rotating machinery such as turbines, compressors, pumps, and motors

-

Condition monitoring systems for predictive maintenance

-

Vibration monitoring and diagnostics in industrial facilities

-

Machinery protection systems to prevent critical failures

-

Measurement of shaft axial position, radial vibration, and eccentricity

-

Monitoring of slow-rolling or standstill machinery for thermal growth and alignment

Its adaptability and high accuracy make it an ideal choice for demanding industrial environments.

Product Advantages

High Measurement Accuracy: Delivers precise data essential for reliable machinery diagnostics.

Wide Operating Temperature Range: Suitable for harsh industrial environments.

Rugged Design: Built to withstand mechanical stress, thermal expansion, and vibration.

Easy Integration: Fully compatible with Bently Nevada monitoring systems and many third-party systems.

Customizable Cable Lengths: Enhances installation flexibility based on site requirements.

Long-Term Reliability: Proven durability in continuous operation over years.

Compact Size: Facilitates installation in constrained spaces.

Non-contact Measurement: Reduces wear and ensures stable readings over time.

FAQ

Q1: What does the Bently Nevada 84145-01 primarily measure?

A1: It measures shaft displacement and vibration, especially in critical rotating machinery.

Q2: Can the probe handle extreme temperatures?

A2: Yes, it operates reliably between –35 °C to +175 °C, suitable for many industrial settings.

Q3: Is it compatible only with Bently Nevada systems?

A3: While optimized for Bently Nevada systems, it can integrate with other systems that accept compatible voltage signals.

Q4: What industries typically use this sensor?

A4: Oil & gas, power generation, petrochemicals, and heavy industrial machinery sectors.

Q5: Does it require regular recalibration?

A5: Minimal recalibration is needed; regular inspections are recommended for critical machinery.

Q6: How does non-contact measurement benefit operations?

A6: It eliminates mechanical wear, leading to consistent accuracy over time.

Q7: Can cable lengths be customized?

A7: Yes, standard cables are typically 1 m, but custom lengths are available on request.

Q8: What is the output signal type?

A8: It outputs a voltage proportional to the measured displacement.

Q9: Is it suitable for slow-rolling equipment?

A9: Yes, it accurately measures thermal growth and shaft position even at low speeds.

Q10: What makes it different from general vibration sensors?

A10: It offers precise proximity (displacement) measurement instead of just vibration velocity or acceleration, critical for protection systems.

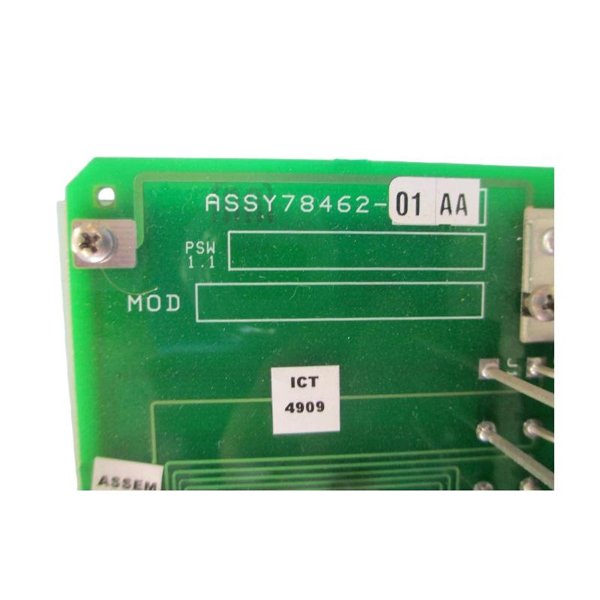

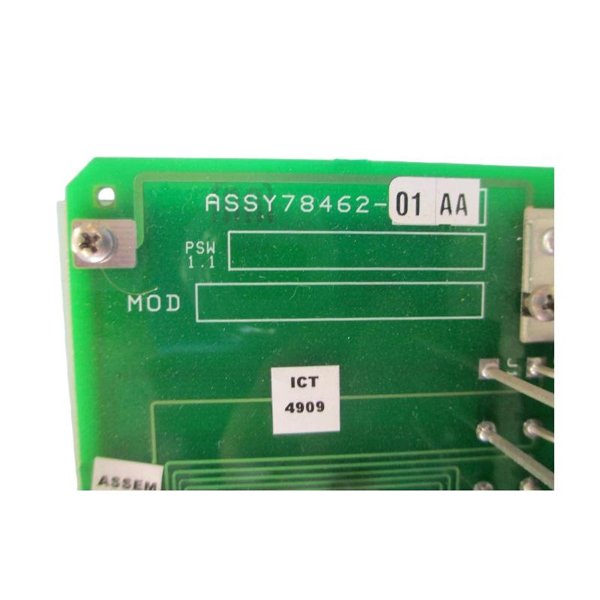

Bently Nevada 84145-01 XDUCR I/O and Recording Terminal

Manufacturer:Bently Nevada

Product Number:84145-01

Product Type:XDUCR I/O and Recording Terminal

Origin:USA

Dimensions:51x 102x 229mm

Weight:0.35 kg

Views:23

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

With robust design and reliable performance, the 84145-01 helps ensure the safety, efficiency, and longevity of expensive machinery assets by providing precise, real-time data about shaft position and dynamic vibration. Its compact design allows for easier installation in tight spaces without sacrificing measurement accuracy.

Product Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 84145-01 |

| Measurement Range | 0 to 2 mm (0 to 80 mils) |

| Sensitivity | 7.87 mV/μm (200 mV/mil) |

| Dimension | 51x 102x 229mm |

| Weight | 0.35 kg |

| Operating Temperature | –35 °C to +175 °C (–31 °F to +347 °F) |

| Storage Temperature | –40 °C to +200 °C (–40 °F to +392 °F) |

| Output Signal | Voltage proportional to target displacement |

| Power Supply | ±15 VDC from monitoring system |

| Housing Material | Stainless steel |

| Insulation Resistance | > 100 MΩ at 500 VDC |

Product Applications

The Bently Nevada 84145-01 is widely used in:

-

Large rotating machinery such as turbines, compressors, pumps, and motors

-

Condition monitoring systems for predictive maintenance

-

Vibration monitoring and diagnostics in industrial facilities

-

Machinery protection systems to prevent critical failures

-

Measurement of shaft axial position, radial vibration, and eccentricity

-

Monitoring of slow-rolling or standstill machinery for thermal growth and alignment

Its adaptability and high accuracy make it an ideal choice for demanding industrial environments.

Product Advantages

High Measurement Accuracy: Delivers precise data essential for reliable machinery diagnostics.

Wide Operating Temperature Range: Suitable for harsh industrial environments.

Rugged Design: Built to withstand mechanical stress, thermal expansion, and vibration.

Easy Integration: Fully compatible with Bently Nevada monitoring systems and many third-party systems.

Customizable Cable Lengths: Enhances installation flexibility based on site requirements.

Long-Term Reliability: Proven durability in continuous operation over years.

Compact Size: Facilitates installation in constrained spaces.

Non-contact Measurement: Reduces wear and ensures stable readings over time.

FAQ

Q1: What does the Bently Nevada 84145-01 primarily measure?

A1: It measures shaft displacement and vibration, especially in critical rotating machinery.

Q2: Can the probe handle extreme temperatures?

A2: Yes, it operates reliably between –35 °C to +175 °C, suitable for many industrial settings.

Q3: Is it compatible only with Bently Nevada systems?

A3: While optimized for Bently Nevada systems, it can integrate with other systems that accept compatible voltage signals.

Q4: What industries typically use this sensor?

A4: Oil & gas, power generation, petrochemicals, and heavy industrial machinery sectors.

Q5: Does it require regular recalibration?

A5: Minimal recalibration is needed; regular inspections are recommended for critical machinery.

Q6: How does non-contact measurement benefit operations?

A6: It eliminates mechanical wear, leading to consistent accuracy over time.

Q7: Can cable lengths be customized?

A7: Yes, standard cables are typically 1 m, but custom lengths are available on request.

Q8: What is the output signal type?

A8: It outputs a voltage proportional to the measured displacement.

Q9: Is it suitable for slow-rolling equipment?

A9: Yes, it accurately measures thermal growth and shaft position even at low speeds.

Q10: What makes it different from general vibration sensors?

A10: It offers precise proximity (displacement) measurement instead of just vibration velocity or acceleration, critical for protection systems.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...