Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

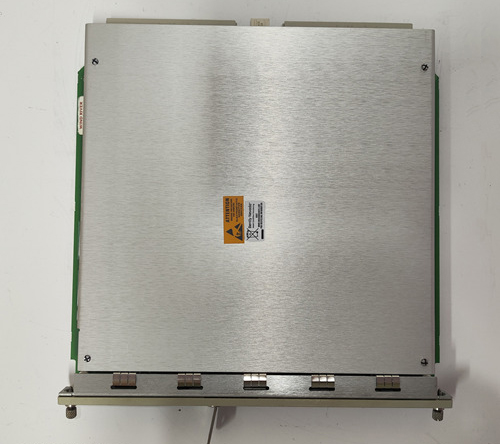

Bently Nevada 84147-01 XDUCR I/O and Recording Terminal

Manufacturer:Bently Nevada

Product Number:84147-01

Product Type:XDUCR I/O and Recording Terminal

Origin:USA

Dimensions:51x 102x 229mm

Weight:0.35 kg

Views:24

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 84147-01 is a high-performance vibration monitoring module designed for industrial machinery protection and condition monitoring. It is part of the 3500 Series by Bently Nevada, a leading brand in predictive maintenance and machinery health solutions. This module ensures reliable detection of vibration, speed, and other critical parameters to prevent equipment failure.

Product Specifications

The 84147-01 module is engineered for rugged industrial environments, offering precise measurements and seamless integration with Bently Nevada’s monitoring systems.

| Parameter | Value |

|---|---|

| Input Channels | 2 (Dual-channel configuration) |

| Measurement Range | 0-20 mA / 0-10 VDC (configurable) |

| Frequency Response | 0.5 Hz to 15 kHz |

| Power Supply | 18-30 VDC |

| Operating Temp. | -40°C to +85°C (-40°F to +185°F) |

| Dimensions | 51x 102x 229mm |

| Weight | 0.35 kg |

| Enclosure Rating | IP67 (Dust/Waterproof) |

| Communication | RS-485 / Modbus Protocol |

| Mounting | DIN rail or panel mounting |

Applications

The 84147-01 is widely used in industries requiring precise machinery health monitoring, including:

Power Generation: Steam and gas turbines, generators.

Chemical & Petrochemical: Rotating equipment monitoring.

Mining & Metals: Crushers, conveyors, and heavy machinery.

Water Treatment: Large pumps and motors.

Product Advantages

High Accuracy: Provides reliable vibration data for predictive maintenance.

Robust Design: Built for harsh industrial environments (IP67 rated).

Easy Integration: Compatible with Bently Nevada’s 3500 Series and third-party systems.

Dual-Channel Input: Allows monitoring of two separate sensors simultaneously.

Wide Temp. Range: Operates in extreme temperatures (-40°C to +85°C).

Low Maintenance: Solid-state design ensures long-term reliability.

Frequently Asked Questions (FAQ)

Q1: What type of sensors are compatible with the 84147-01?

A: It supports accelerometers, proximity probes, and velocity sensors (0-20 mA / 0-10 VDC).

Q2: Can this module be used in hazardous areas?

A: Yes, with proper intrinsic safety barriers (ATEX/IECEx certifications may apply).

Q3: What is the maximum cable length for sensor connections?

A: Up to 300 meters (shielded cable recommended).

Q4: Does it support wireless communication?

A: No, it uses wired RS-485/Modbus for data transmission.

Q5: How is the module powered?

A: 18-30 VDC power supply (redundant power options available).

Q6: Is calibration required?

A: Factory-calibrated, but field verification is recommended annually.

Q7: Can it be used with non-Bently Nevada systems?

A: Yes, via standard Modbus protocol.

Q8: What is the typical lifespan of the module?

A: 5+ years with proper maintenance.

Q9: Does it include software for diagnostics?

A: Requires Bently Nevada’s System 1 or third-party SCADA integration.

Q10: Is there a warranty?

A: Standard 12-month warranty (extended options available).

Bently Nevada 84147-01 XDUCR I/O and Recording Terminal

Manufacturer:Bently Nevada

Product Number:84147-01

Product Type:XDUCR I/O and Recording Terminal

Origin:USA

Dimensions:51x 102x 229mm

Weight:0.35 kg

Views:24

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 84147-01 is a high-performance vibration monitoring module designed for industrial machinery protection and condition monitoring. It is part of the 3500 Series by Bently Nevada, a leading brand in predictive maintenance and machinery health solutions. This module ensures reliable detection of vibration, speed, and other critical parameters to prevent equipment failure.

Product Specifications

The 84147-01 module is engineered for rugged industrial environments, offering precise measurements and seamless integration with Bently Nevada’s monitoring systems.

| Parameter | Value |

|---|---|

| Input Channels | 2 (Dual-channel configuration) |

| Measurement Range | 0-20 mA / 0-10 VDC (configurable) |

| Frequency Response | 0.5 Hz to 15 kHz |

| Power Supply | 18-30 VDC |

| Operating Temp. | -40°C to +85°C (-40°F to +185°F) |

| Dimensions | 51x 102x 229mm |

| Weight | 0.35 kg |

| Enclosure Rating | IP67 (Dust/Waterproof) |

| Communication | RS-485 / Modbus Protocol |

| Mounting | DIN rail or panel mounting |

Applications

The 84147-01 is widely used in industries requiring precise machinery health monitoring, including:

Power Generation: Steam and gas turbines, generators.

Chemical & Petrochemical: Rotating equipment monitoring.

Mining & Metals: Crushers, conveyors, and heavy machinery.

Water Treatment: Large pumps and motors.

Product Advantages

High Accuracy: Provides reliable vibration data for predictive maintenance.

Robust Design: Built for harsh industrial environments (IP67 rated).

Easy Integration: Compatible with Bently Nevada’s 3500 Series and third-party systems.

Dual-Channel Input: Allows monitoring of two separate sensors simultaneously.

Wide Temp. Range: Operates in extreme temperatures (-40°C to +85°C).

Low Maintenance: Solid-state design ensures long-term reliability.

Frequently Asked Questions (FAQ)

Q1: What type of sensors are compatible with the 84147-01?

A: It supports accelerometers, proximity probes, and velocity sensors (0-20 mA / 0-10 VDC).

Q2: Can this module be used in hazardous areas?

A: Yes, with proper intrinsic safety barriers (ATEX/IECEx certifications may apply).

Q3: What is the maximum cable length for sensor connections?

A: Up to 300 meters (shielded cable recommended).

Q4: Does it support wireless communication?

A: No, it uses wired RS-485/Modbus for data transmission.

Q5: How is the module powered?

A: 18-30 VDC power supply (redundant power options available).

Q6: Is calibration required?

A: Factory-calibrated, but field verification is recommended annually.

Q7: Can it be used with non-Bently Nevada systems?

A: Yes, via standard Modbus protocol.

Q8: What is the typical lifespan of the module?

A: 5+ years with proper maintenance.

Q9: Does it include software for diagnostics?

A: Requires Bently Nevada’s System 1 or third-party SCADA integration.

Q10: Is there a warranty?

A: Standard 12-month warranty (extended options available).

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...