Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

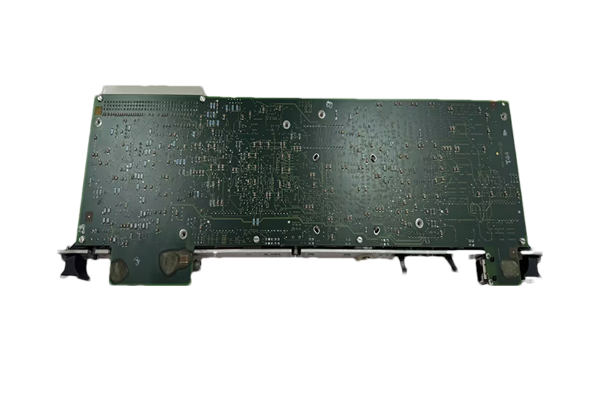

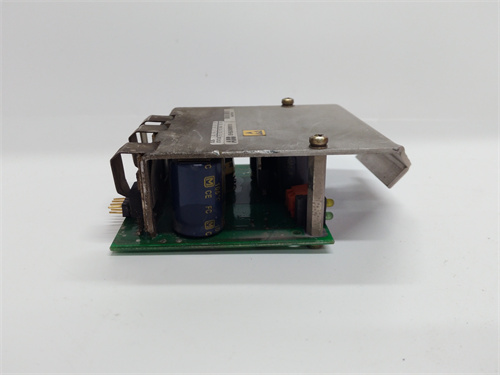

ABB PM866AK02 3BSE081637R1 CPU controller unit

Manufacturer:ABB

Product Number:PM866AK02 3BSE081637R1

Condition:CPU controller unit

Origin:Sweden

Dimensions:135 × 186 × 119 mm

Weight:2.7 kg

Views:42

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

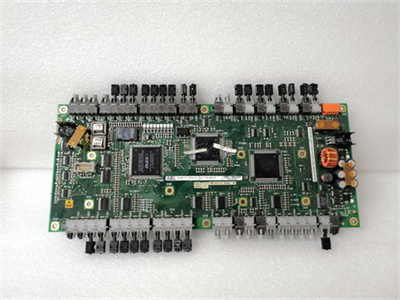

The ABB PM866AK02 (Part Number: 3BSE081637R1) is a high-performance CPU module designed for ABB’s AC 800M controller family, which is widely deployed in industrial automation and process control systems. This controller unit is an enhanced version of the PM866 series, incorporating upgraded hardware, better processing speed, and improved memory handling to meet the increasing demands of modern automation.

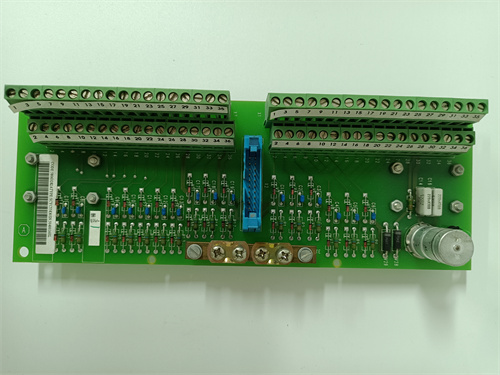

PM866AK02 supports a wide range of communication protocols and seamlessly integrates with ABB’s Control Builder M, allowing advanced logic programming, distributed control, and centralized monitoring. It is typically used in DCS (Distributed Control Systems) such as ABB 800xA.

Product Features & Advantages

High-speed Performance: The PM866AK02 offers improved CPU speed for fast processing and real-time response.

Integrated Redundancy Support: Enables CPU redundancy configurations for fault-tolerant control systems.

Large Memory Capacity: Supports higher application sizes and data logging, ideal for complex processes.

Modular & Scalable Design: Flexible design for expansion, enabling future system upgrades.

Multi-protocol Communication: Includes support for PROFIBUS DP, Ethernet, MODBUS, and more.

Compact Size & Robust Design: Designed for industrial environments with high mechanical reliability.

Easy Engineering with Control Builder M: Ensures compatibility and intuitive configuration with ABB software tools.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | PM866AK02 |

| Part Number | 3BSE081637R1 |

| Processor | 32-bit RISC CPU |

| CPU Clock Speed | 100 MHz |

| Memory – Application | 4 MB (user memory) |

| Memory – Flash | 16 MB |

| Communication Ports | 1 x Ethernet, 2 x Serial (RS232/RS485) |

| Redundancy | Supported (redundant configuration) |

| Supported Protocols | MODBUS, PROFIBUS DP, TCP/IP, IEC 60870 |

| Power Supply Voltage | 24 V DC |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -40°C to +70°C |

| Humidity | 5% to 95% (non-condensing) |

| Mounting Type | DIN Rail / Panel |

| Dimensions (W x H x D) | 135 × 186 × 119 mm |

| Weight | 2.7 kg |

| Certifications | CE, UL, CSA, RoHS |

| Programming Environment | Control Builder M |

Applications

The ABB PM866AK02 is widely used in a variety of industrial and infrastructure sectors, including:

Petrochemical and Chemical Plants: For managing complex chemical process sequences.

Power Generation & Utilities: Suitable for turbine control, boiler management, and auxiliary systems.

Water and Wastewater Management: Ideal for pump station automation and SCADA system integration.

Pulp & Paper Industry: Used for continuous process control and material flow optimization.

Food & Beverage: Enables high-speed packaging, batching, and process consistency.

Marine and Offshore Platforms: Used in engine control and power distribution systems.

Installation Guidelines

Preparation: Ensure a clean and grounded control panel with adequate space for airflow.

Mounting: Install the unit on a DIN rail or secure to a flat panel using screws.

Wiring: Connect power supply (24 VDC), communication cables, and I/O interfaces.

Configuration: Use ABB’s Control Builder M software to load the control program and set parameters.

Redundancy Setup: If required, pair with another PM866AK02 for redundant configuration via the redundancy link.

Testing: Run a full I/O and logic test before commissioning.

Frequently Asked Questions (FAQ)

Q1: What software is compatible with the PM866AK02?

A1: The PM866AK02 is configured using ABB’s Control Builder M software, part of the 800xA automation platform.

Q2: Is the PM866AK02 suitable for redundant CPU configurations?

A2: Yes, it supports CPU redundancy for critical applications that require high availability.

Q3: Can this module be integrated with third-party systems?

A3: Yes, through standard protocols like MODBUS, TCP/IP, and PROFIBUS DP.

Q4: How many I/O modules can be connected?

A4: Up to 12 S800 I/O modules can be connected locally, and more via remote configurations.

Q5: Does the PM866AK02 have onboard diagnostics?

A5: Yes, it includes self-diagnostics for memory, processor load, and communication health.

Q6: What is the primary difference between PM866 and PM866AK02?

A6: PM866AK02 offers enhanced memory, better performance, and extended protocol support compared to the standard PM866.

Q7: How is firmware updated on this device?

A7: Firmware can be updated via Control Builder M or through a service tool over Ethernet.

Q8: Can I use the PM866AK02 in a hazardous area?

A8: It should be installed in a certified enclosure if used in hazardous areas, as per local safety standards.

Q9: What maintenance is required?

A9: Minimal; includes periodic inspection of connections and firmware checks.

Q10: Is technical support available for this model?

A10: Yes, ABB offers global technical support and documentation for this model.

ABB PM866AK02 3BSE081637R1 CPU controller unit

Manufacturer:ABB

Product Number:PM866AK02 3BSE081637R1

Condition:CPU controller unit

Origin:Sweden

Dimensions:135 × 186 × 119 mm

Weight:2.7 kg

Views:42

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PM866AK02 (Part Number: 3BSE081637R1) is a high-performance CPU module designed for ABB’s AC 800M controller family, which is widely deployed in industrial automation and process control systems. This controller unit is an enhanced version of the PM866 series, incorporating upgraded hardware, better processing speed, and improved memory handling to meet the increasing demands of modern automation.

PM866AK02 supports a wide range of communication protocols and seamlessly integrates with ABB’s Control Builder M, allowing advanced logic programming, distributed control, and centralized monitoring. It is typically used in DCS (Distributed Control Systems) such as ABB 800xA.

Product Features & Advantages

High-speed Performance: The PM866AK02 offers improved CPU speed for fast processing and real-time response.

Integrated Redundancy Support: Enables CPU redundancy configurations for fault-tolerant control systems.

Large Memory Capacity: Supports higher application sizes and data logging, ideal for complex processes.

Modular & Scalable Design: Flexible design for expansion, enabling future system upgrades.

Multi-protocol Communication: Includes support for PROFIBUS DP, Ethernet, MODBUS, and more.

Compact Size & Robust Design: Designed for industrial environments with high mechanical reliability.

Easy Engineering with Control Builder M: Ensures compatibility and intuitive configuration with ABB software tools.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | PM866AK02 |

| Part Number | 3BSE081637R1 |

| Processor | 32-bit RISC CPU |

| CPU Clock Speed | 100 MHz |

| Memory – Application | 4 MB (user memory) |

| Memory – Flash | 16 MB |

| Communication Ports | 1 x Ethernet, 2 x Serial (RS232/RS485) |

| Redundancy | Supported (redundant configuration) |

| Supported Protocols | MODBUS, PROFIBUS DP, TCP/IP, IEC 60870 |

| Power Supply Voltage | 24 V DC |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -40°C to +70°C |

| Humidity | 5% to 95% (non-condensing) |

| Mounting Type | DIN Rail / Panel |

| Dimensions (W x H x D) | 135 × 186 × 119 mm |

| Weight | 2.7 kg |

| Certifications | CE, UL, CSA, RoHS |

| Programming Environment | Control Builder M |

Applications

The ABB PM866AK02 is widely used in a variety of industrial and infrastructure sectors, including:

Petrochemical and Chemical Plants: For managing complex chemical process sequences.

Power Generation & Utilities: Suitable for turbine control, boiler management, and auxiliary systems.

Water and Wastewater Management: Ideal for pump station automation and SCADA system integration.

Pulp & Paper Industry: Used for continuous process control and material flow optimization.

Food & Beverage: Enables high-speed packaging, batching, and process consistency.

Marine and Offshore Platforms: Used in engine control and power distribution systems.

Installation Guidelines

Preparation: Ensure a clean and grounded control panel with adequate space for airflow.

Mounting: Install the unit on a DIN rail or secure to a flat panel using screws.

Wiring: Connect power supply (24 VDC), communication cables, and I/O interfaces.

Configuration: Use ABB’s Control Builder M software to load the control program and set parameters.

Redundancy Setup: If required, pair with another PM866AK02 for redundant configuration via the redundancy link.

Testing: Run a full I/O and logic test before commissioning.

Frequently Asked Questions (FAQ)

Q1: What software is compatible with the PM866AK02?

A1: The PM866AK02 is configured using ABB’s Control Builder M software, part of the 800xA automation platform.

Q2: Is the PM866AK02 suitable for redundant CPU configurations?

A2: Yes, it supports CPU redundancy for critical applications that require high availability.

Q3: Can this module be integrated with third-party systems?

A3: Yes, through standard protocols like MODBUS, TCP/IP, and PROFIBUS DP.

Q4: How many I/O modules can be connected?

A4: Up to 12 S800 I/O modules can be connected locally, and more via remote configurations.

Q5: Does the PM866AK02 have onboard diagnostics?

A5: Yes, it includes self-diagnostics for memory, processor load, and communication health.

Q6: What is the primary difference between PM866 and PM866AK02?

A6: PM866AK02 offers enhanced memory, better performance, and extended protocol support compared to the standard PM866.

Q7: How is firmware updated on this device?

A7: Firmware can be updated via Control Builder M or through a service tool over Ethernet.

Q8: Can I use the PM866AK02 in a hazardous area?

A8: It should be installed in a certified enclosure if used in hazardous areas, as per local safety standards.

Q9: What maintenance is required?

A9: Minimal; includes periodic inspection of connections and firmware checks.

Q10: Is technical support available for this model?

A10: Yes, ABB offers global technical support and documentation for this model.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...