Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

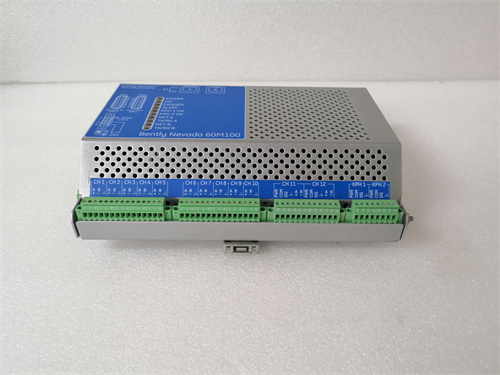

Bently Nevada 330103-00-04-10-02-01 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-00-04-10-02-01

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Dimensions:Total Length : 1.0 meter

Weight:0.323kg

Views:25

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-04-10-02-01 is an 8 mm diameter proximity probe from the 3300 XL series, designed to provide precise shaft vibration and position monitoring for rotating machinery in industrial environments. This probe is ideal for applications such as turbines, compressors, motors, and pumps, where reliable and accurate shaft position feedback is essential for machinery protection and condition monitoring.

Constructed with robust materials and featuring a shielded cable, the probe delivers stable signals with high immunity to electromagnetic interference. Its proven design helps in early detection of shaft anomalies, preventing unexpected equipment failures and improving operational safety.

Key Features

-

8 mm diameter sensing tip for enhanced sensitivity

-

Compatible with Bently Nevada 3300 XL monitoring systems

-

Durable stainless steel probe housing for harsh environments

-

Shielded cable to minimize electromagnetic interference (EMI)

-

Extended operating temperature range from -40°C to +120°C

-

Available in multiple cable lengths for flexible installations

-

High-frequency response for accurate vibration and position data

-

Reliable, long-lasting performance with minimal maintenance

Technical Specifications

| Item | Specification |

|---|---|

| Manufacturer | Bently Nevada (a Baker Hughes Company) |

| Model Number | 330103-00-04-10-02-01 |

| Series | 3300 XL Series |

| Diameter | Total Length : 1.0 meter |

| Sensing Distance | 0.15 to 5 mm (typical) |

| Operating Temperature Range | -40°C to +120°C (-40°F to +248°F) |

| Cable Length | Standard 10 meters (custom lengths available) |

| Probe Body Material | Stainless steel |

| Connector Type | Integral connector or bare cable (varies by configuration) |

| Frequency Response | Up to 40 kHz |

| Weight | 0.323 kg |

| Environmental Protection | IP67 rated for dust and water resistance |

| Application | Shaft vibration and position monitoring in rotating machinery |

Industry Applications

Power Generation — Monitoring turbines and generators

Oil & Gas — Protection of compressors and pumps

Mining and Metals — Vibration surveillance of heavy machinery

Petrochemical — Process machinery condition monitoring

Marine and Shipbuilding — Monitoring critical rotating equipment

Manufacturing — Motor and spindle shaft position measurement

Product Advantages

High Accuracy — Provides precise shaft position and vibration measurements

Robust Durability — Designed to withstand harsh operating conditions

EMI Protection — Shielded cable reduces signal interference

Flexible Installation — Multiple cable length options for various applications

Field-Proven Reliability — Trusted technology with decades of industrial use

Minimal Maintenance — Long service life reduces downtime and repair costs

Frequently Asked Questions (FAQ)

Q: Which monitoring systems is this probe compatible with?

A: Designed for use with Bently Nevada 3300 XL monitoring systems.

Q: What is the typical sensing distance?

A: Typically between 0.15 and 5 mm.

Q: What temperature range can this probe operate in?

A: From -40°C to +120°C.

Q: Is the cable shielded to reduce noise?

A: Yes, it has a shielded cable for EMI protection.

Q: Are custom cable lengths available?

A: Yes, standard 10 m cables are available with custom lengths upon request.

Q: What is the environmental protection rating?

A: The probe is IP67 rated, protecting against dust and water ingress.

Q: What material is the probe housing made of?

A: Stainless steel for durability and corrosion resistance.

Q: In which industries is this probe commonly used?

A: Power generation, oil & gas, mining, petrochemical, marine, and manufacturing.

Q: How does the probe maintain signal integrity?

A: Through a shielded cable and robust construction.

Q: What maintenance is required?

A: Minimal maintenance; periodic inspection is recommended.

Bently Nevada 330103-00-04-10-02-01 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-00-04-10-02-01

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Dimensions:Total Length : 1.0 meter

Weight:0.323kg

Views:25

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-04-10-02-01 is an 8 mm diameter proximity probe from the 3300 XL series, designed to provide precise shaft vibration and position monitoring for rotating machinery in industrial environments. This probe is ideal for applications such as turbines, compressors, motors, and pumps, where reliable and accurate shaft position feedback is essential for machinery protection and condition monitoring.

Constructed with robust materials and featuring a shielded cable, the probe delivers stable signals with high immunity to electromagnetic interference. Its proven design helps in early detection of shaft anomalies, preventing unexpected equipment failures and improving operational safety.

Key Features

-

8 mm diameter sensing tip for enhanced sensitivity

-

Compatible with Bently Nevada 3300 XL monitoring systems

-

Durable stainless steel probe housing for harsh environments

-

Shielded cable to minimize electromagnetic interference (EMI)

-

Extended operating temperature range from -40°C to +120°C

-

Available in multiple cable lengths for flexible installations

-

High-frequency response for accurate vibration and position data

-

Reliable, long-lasting performance with minimal maintenance

Technical Specifications

| Item | Specification |

|---|---|

| Manufacturer | Bently Nevada (a Baker Hughes Company) |

| Model Number | 330103-00-04-10-02-01 |

| Series | 3300 XL Series |

| Diameter | Total Length : 1.0 meter |

| Sensing Distance | 0.15 to 5 mm (typical) |

| Operating Temperature Range | -40°C to +120°C (-40°F to +248°F) |

| Cable Length | Standard 10 meters (custom lengths available) |

| Probe Body Material | Stainless steel |

| Connector Type | Integral connector or bare cable (varies by configuration) |

| Frequency Response | Up to 40 kHz |

| Weight | 0.323 kg |

| Environmental Protection | IP67 rated for dust and water resistance |

| Application | Shaft vibration and position monitoring in rotating machinery |

Industry Applications

Power Generation — Monitoring turbines and generators

Oil & Gas — Protection of compressors and pumps

Mining and Metals — Vibration surveillance of heavy machinery

Petrochemical — Process machinery condition monitoring

Marine and Shipbuilding — Monitoring critical rotating equipment

Manufacturing — Motor and spindle shaft position measurement

Product Advantages

High Accuracy — Provides precise shaft position and vibration measurements

Robust Durability — Designed to withstand harsh operating conditions

EMI Protection — Shielded cable reduces signal interference

Flexible Installation — Multiple cable length options for various applications

Field-Proven Reliability — Trusted technology with decades of industrial use

Minimal Maintenance — Long service life reduces downtime and repair costs

Frequently Asked Questions (FAQ)

Q: Which monitoring systems is this probe compatible with?

A: Designed for use with Bently Nevada 3300 XL monitoring systems.

Q: What is the typical sensing distance?

A: Typically between 0.15 and 5 mm.

Q: What temperature range can this probe operate in?

A: From -40°C to +120°C.

Q: Is the cable shielded to reduce noise?

A: Yes, it has a shielded cable for EMI protection.

Q: Are custom cable lengths available?

A: Yes, standard 10 m cables are available with custom lengths upon request.

Q: What is the environmental protection rating?

A: The probe is IP67 rated, protecting against dust and water ingress.

Q: What material is the probe housing made of?

A: Stainless steel for durability and corrosion resistance.

Q: In which industries is this probe commonly used?

A: Power generation, oil & gas, mining, petrochemical, marine, and manufacturing.

Q: How does the probe maintain signal integrity?

A: Through a shielded cable and robust construction.

Q: What maintenance is required?

A: Minimal maintenance; periodic inspection is recommended.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...