Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

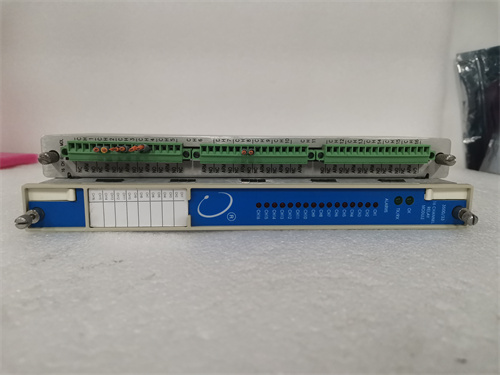

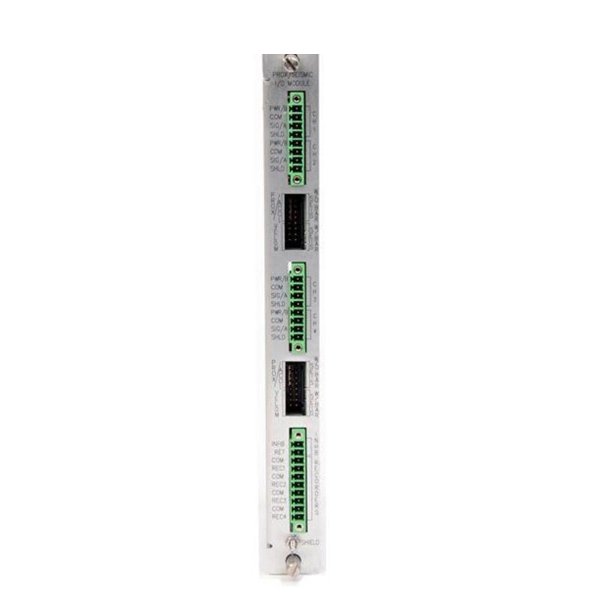

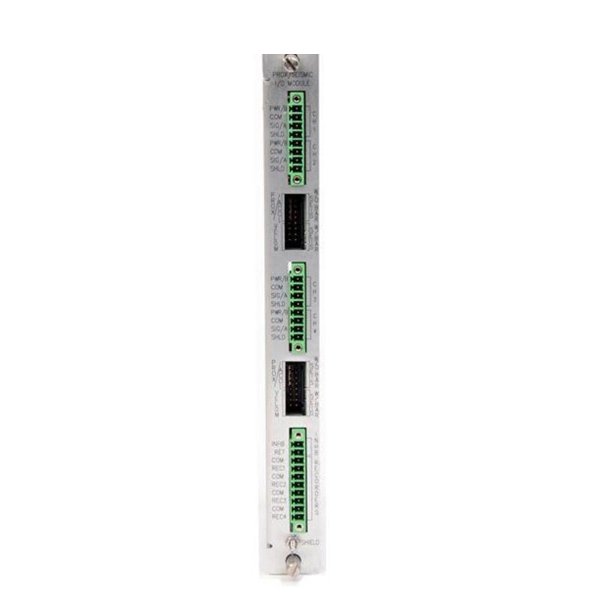

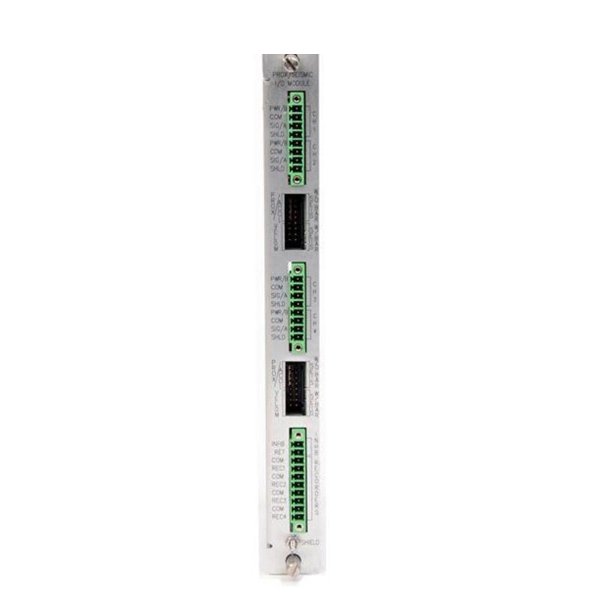

Bently Nevada 3500/42 128229-01 Proximitor Seismic I/O Module

Manufacturer:Bently Nevada

Product Number:3500/42 128229-01

Product Type:Proximitor Seismic I/O Module

Origin:USA

Dimensions:241.3 x 24.4 x 163.1mm

Weight :0.46 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42 128229-01 Proximitor Seismic I/O Module is a critical component of the 3500 Series machinery protection system. It is designed to monitor seismic vibration signals from rotating machinery, enabling early detection of abnormal conditions. This module converts input signals from seismic sensors into signals that can be processed and analyzed by the 3500 Series monitor system.

Engineered for high reliability in demanding industrial environments, this module ensures precise measurement of machinery vibrations and accelerations, providing operators with real-time insights for predictive maintenance. The rugged design allows installation in harsh conditions while maintaining high signal fidelity and operational safety.

Product Advantages

High Accuracy: Provides precise seismic signal conversion and measurement, minimizing false alarms.

Reliability: Designed for continuous operation in harsh industrial environments.

Easy Integration: Fully compatible with other 3500 Series modules, ensuring seamless system operation.

Compact Design: Optimized size for efficient installation in control cabinets.

Maintenance-Friendly: Modular architecture allows quick replacement or service without extended downtime.

Advanced Diagnostics: Supports self-check features and fault diagnostics to enhance system reliability.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/42 128229-01 |

| Function | Proximitor Seismic I/O Module |

| Input Type | Seismic sensor signals (velocity/acceleration) |

| Output Type | Processed 3500 Series compatible signals |

| Supply Voltage | 24 VDC nominal |

| Power Consumption | 5 W typical |

| Operating Temperature | -40°C to +85°C |

| Storage Temperature | -55°C to +125°C |

| Humidity | 5% – 95% non-condensing |

| Dimensions | 241.3 x 24.4 x 163.1mm |

| Weight | 0.46 kg |

| Mounting | DIN rail compatible |

| Response Frequency Range | 0.5 Hz – 500 Hz |

| Certifications | CE, CSA, ATEX (selected versions) |

Product Applications

-

Turbines (steam, gas, and hydro) monitoring

-

Compressors and pumps vibration analysis

-

High-speed rotating machinery protection

-

Seismic activity monitoring for critical machinery

-

Predictive maintenance systems for industrial plants

This module is particularly valuable in industries where unplanned downtime can result in significant safety or economic consequences, such as power generation, petrochemical plants, and heavy manufacturing.

FAQ

Q1: What type of sensors can be connected to the 3500/42 module?

A: It supports standard seismic sensors providing velocity or acceleration outputs compatible with 3500 Series systems.

Q2: Can this module operate in extreme temperatures?

A: Yes, it is rated for -40°C to +85°C operating temperatures.

Q3: How is the module powered?

A: The module uses a nominal 24 VDC power supply, consuming approximately 5 W.

Q4: Is it compatible with all 3500 Series monitors?

A: Yes, it is fully compatible with other 3500 Series monitoring and display modules.

Q5: What are the mounting options?

A: The module is designed for DIN rail mounting in standard industrial control panels.

Q6: How does it help in predictive maintenance?

A: By converting seismic signals into analyzable data, it helps detect early-stage machinery issues, reducing unplanned downtime.

Q7: What is the response frequency range of this module?

A: The response frequency range is 0.5 Hz to 500 Hz, suitable for most rotating machinery applications.

Q8: Is there any diagnostic support included?

A: Yes, it has built-in fault detection and diagnostic features to ensure continuous monitoring integrity.

Q9: Can the module be replaced without shutting down the entire system?

A: Yes, its modular design allows for hot-swap replacement in most configurations.

Q10: Are there any environmental certifications for safety?

A: Certain versions of the module carry CE, CSA, and ATEX certifications for hazardous environments.

Bently Nevada 3500/42 128229-01 Proximitor Seismic I/O Module

Manufacturer:Bently Nevada

Product Number:3500/42 128229-01

Product Type:Proximitor Seismic I/O Module

Origin:USA

Dimensions:241.3 x 24.4 x 163.1mm

Weight :0.46 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42 128229-01 Proximitor Seismic I/O Module is a critical component of the 3500 Series machinery protection system. It is designed to monitor seismic vibration signals from rotating machinery, enabling early detection of abnormal conditions. This module converts input signals from seismic sensors into signals that can be processed and analyzed by the 3500 Series monitor system.

Engineered for high reliability in demanding industrial environments, this module ensures precise measurement of machinery vibrations and accelerations, providing operators with real-time insights for predictive maintenance. The rugged design allows installation in harsh conditions while maintaining high signal fidelity and operational safety.

Product Advantages

High Accuracy: Provides precise seismic signal conversion and measurement, minimizing false alarms.

Reliability: Designed for continuous operation in harsh industrial environments.

Easy Integration: Fully compatible with other 3500 Series modules, ensuring seamless system operation.

Compact Design: Optimized size for efficient installation in control cabinets.

Maintenance-Friendly: Modular architecture allows quick replacement or service without extended downtime.

Advanced Diagnostics: Supports self-check features and fault diagnostics to enhance system reliability.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/42 128229-01 |

| Function | Proximitor Seismic I/O Module |

| Input Type | Seismic sensor signals (velocity/acceleration) |

| Output Type | Processed 3500 Series compatible signals |

| Supply Voltage | 24 VDC nominal |

| Power Consumption | 5 W typical |

| Operating Temperature | -40°C to +85°C |

| Storage Temperature | -55°C to +125°C |

| Humidity | 5% – 95% non-condensing |

| Dimensions | 241.3 x 24.4 x 163.1mm |

| Weight | 0.46 kg |

| Mounting | DIN rail compatible |

| Response Frequency Range | 0.5 Hz – 500 Hz |

| Certifications | CE, CSA, ATEX (selected versions) |

Product Applications

-

Turbines (steam, gas, and hydro) monitoring

-

Compressors and pumps vibration analysis

-

High-speed rotating machinery protection

-

Seismic activity monitoring for critical machinery

-

Predictive maintenance systems for industrial plants

This module is particularly valuable in industries where unplanned downtime can result in significant safety or economic consequences, such as power generation, petrochemical plants, and heavy manufacturing.

FAQ

Q1: What type of sensors can be connected to the 3500/42 module?

A: It supports standard seismic sensors providing velocity or acceleration outputs compatible with 3500 Series systems.

Q2: Can this module operate in extreme temperatures?

A: Yes, it is rated for -40°C to +85°C operating temperatures.

Q3: How is the module powered?

A: The module uses a nominal 24 VDC power supply, consuming approximately 5 W.

Q4: Is it compatible with all 3500 Series monitors?

A: Yes, it is fully compatible with other 3500 Series monitoring and display modules.

Q5: What are the mounting options?

A: The module is designed for DIN rail mounting in standard industrial control panels.

Q6: How does it help in predictive maintenance?

A: By converting seismic signals into analyzable data, it helps detect early-stage machinery issues, reducing unplanned downtime.

Q7: What is the response frequency range of this module?

A: The response frequency range is 0.5 Hz to 500 Hz, suitable for most rotating machinery applications.

Q8: Is there any diagnostic support included?

A: Yes, it has built-in fault detection and diagnostic features to ensure continuous monitoring integrity.

Q9: Can the module be replaced without shutting down the entire system?

A: Yes, its modular design allows for hot-swap replacement in most configurations.

Q10: Are there any environmental certifications for safety?

A: Certain versions of the module carry CE, CSA, and ATEX certifications for hazardous environments.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...