Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

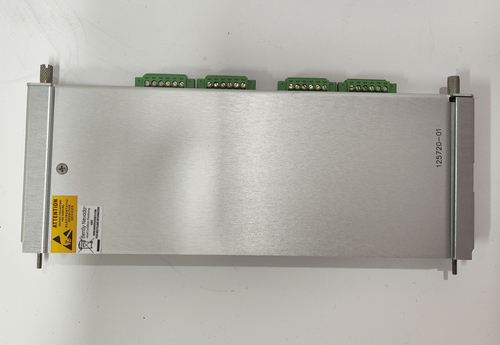

Bently Nevada 330850-51-00 3300 XL 25 mm Proximitor Sensor

Manufacturer:Bently Nevada

Product Number:330850-51-00

Product Type:3300 XL 25 mm Proximitor Sensor

Origin:USA

Cable Length:5.0 meters

Weight:0.255kg

Views:44

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330850-51-00 is part of the 3300 XL 25 mm Proximity Transducer System, designed to accurately measure differential expansion (DE) in large steam turbines. It includes a 25 mm proximity probe, a 5-meter extension cable, and the Proximitor Sensor. With an output scale factor of 0.787 V/mm (20 mV/mil), it supports linear measurements up to 12.7 mm (500 mils).

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 330850-51-00 |

| System Length | 5.0 meters |

| Weight | 0.255 kg (Proximitor Sensor only) |

| Output Scale Factor | 0.787 V/mm (20 mV/mil) |

| Linear Range | 0.63 mm to 13.33 mm (25–525 mils) |

| Operating Temp (Probe) | -35°C to +200°C |

| Short-Term Temp | +250°C (≤24 hrs) |

| Operating Temp (Sensor) | -51°C to +100°C |

| Storage Temp (Sensor) | -51°C to +105°C |

| Frequency Response | 0 to 2.7 kHz |

| Minimum Target Size | 61 mm (2.4 in) diameter |

| Material (Probe) | AISI 304 Stainless Steel |

| Material (Sensor) | A380 Aluminum |

| Environmental Rating | 100% condensing humidity (non-submersible) |

| Certifications | CE, CSA, ATEX, IECEx |

Applications

-

Steam turbine differential expansion (DE) monitoring

-

Shaft movement measurement in power generation

-

High-temperature rotating machinery environments

-

Redundant DE detection with dual-probe configurations

-

Suitable for harsh industrial turbine enclosures

Advantages

-

High survivability in extreme environments (up to 250°C)

-

Fully backward compatible with 7200 and DE Integral systems

-

Moisture protection with dual-sealing and FluidLoc cable

-

Fast, tool-free SpringLoc terminal wiring

-

Compatible with sliding bracket for precise probe alignment

-

Designed for EMI/RFI immunity and CE compliance

FAQs

Q1: What is the maximum linear measurement range?

A1: The linear range is up to 12.7 mm (500 mils).

Q2: Can it be used in high-temperature environments?

A2: Yes, it supports continuous operation at 200°C and short-term peaks up to 250°C.

Q3: Is it compatible with older 7200 series systems?

A3: Yes, it’s designed to replace 7200 25 mm and 35 mm systems with no monitor configuration changes.

Q4: What materials are used in the sensor and probe?

A4: The probe uses AISI 304 stainless steel; the sensor is A380 aluminum.

Q5: What are the output characteristics?

A5: It provides 0.787 V/mm (20 mV/mil), linear from 0.63 mm to 13.33 mm.

Q6: Does it have protection against environmental moisture?

A6: Yes, via a sealed tip and FluidLoc triaxial cable.

Q7: What is the operating temperature range of the Proximitor Sensor?

A7: It operates from -51°C to +100°C.

Q8: Can this model be DIN-mounted?

A8: Yes, the “-51” in the part number specifies DIN mount.

Q9: Are special tools required for installation?

A9: No, SpringLoc terminals allow tool-free installation.

Q10: Is it certified for hazardous environments?

A10: Yes, including CSA, ATEX, and IECEx approvals for Zone 0/Zone 2 installations.

Bently Nevada 330850-51-00 3300 XL 25 mm Proximitor Sensor

Manufacturer:Bently Nevada

Product Number:330850-51-00

Product Type:3300 XL 25 mm Proximitor Sensor

Origin:USA

Cable Length:5.0 meters

Weight:0.255kg

Views:44

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330850-51-00 is part of the 3300 XL 25 mm Proximity Transducer System, designed to accurately measure differential expansion (DE) in large steam turbines. It includes a 25 mm proximity probe, a 5-meter extension cable, and the Proximitor Sensor. With an output scale factor of 0.787 V/mm (20 mV/mil), it supports linear measurements up to 12.7 mm (500 mils).

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 330850-51-00 |

| System Length | 5.0 meters |

| Weight | 0.255 kg (Proximitor Sensor only) |

| Output Scale Factor | 0.787 V/mm (20 mV/mil) |

| Linear Range | 0.63 mm to 13.33 mm (25–525 mils) |

| Operating Temp (Probe) | -35°C to +200°C |

| Short-Term Temp | +250°C (≤24 hrs) |

| Operating Temp (Sensor) | -51°C to +100°C |

| Storage Temp (Sensor) | -51°C to +105°C |

| Frequency Response | 0 to 2.7 kHz |

| Minimum Target Size | 61 mm (2.4 in) diameter |

| Material (Probe) | AISI 304 Stainless Steel |

| Material (Sensor) | A380 Aluminum |

| Environmental Rating | 100% condensing humidity (non-submersible) |

| Certifications | CE, CSA, ATEX, IECEx |

Applications

-

Steam turbine differential expansion (DE) monitoring

-

Shaft movement measurement in power generation

-

High-temperature rotating machinery environments

-

Redundant DE detection with dual-probe configurations

-

Suitable for harsh industrial turbine enclosures

Advantages

-

High survivability in extreme environments (up to 250°C)

-

Fully backward compatible with 7200 and DE Integral systems

-

Moisture protection with dual-sealing and FluidLoc cable

-

Fast, tool-free SpringLoc terminal wiring

-

Compatible with sliding bracket for precise probe alignment

-

Designed for EMI/RFI immunity and CE compliance

FAQs

Q1: What is the maximum linear measurement range?

A1: The linear range is up to 12.7 mm (500 mils).

Q2: Can it be used in high-temperature environments?

A2: Yes, it supports continuous operation at 200°C and short-term peaks up to 250°C.

Q3: Is it compatible with older 7200 series systems?

A3: Yes, it’s designed to replace 7200 25 mm and 35 mm systems with no monitor configuration changes.

Q4: What materials are used in the sensor and probe?

A4: The probe uses AISI 304 stainless steel; the sensor is A380 aluminum.

Q5: What are the output characteristics?

A5: It provides 0.787 V/mm (20 mV/mil), linear from 0.63 mm to 13.33 mm.

Q6: Does it have protection against environmental moisture?

A6: Yes, via a sealed tip and FluidLoc triaxial cable.

Q7: What is the operating temperature range of the Proximitor Sensor?

A7: It operates from -51°C to +100°C.

Q8: Can this model be DIN-mounted?

A8: Yes, the “-51” in the part number specifies DIN mount.

Q9: Are special tools required for installation?

A9: No, SpringLoc terminals allow tool-free installation.

Q10: Is it certified for hazardous environments?

A10: Yes, including CSA, ATEX, and IECEx approvals for Zone 0/Zone 2 installations.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...