Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

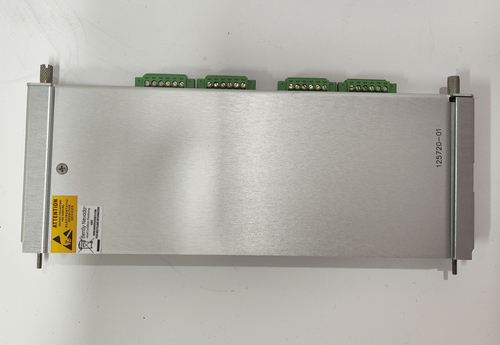

Bently Nevada 330101-00-40-10-02-05 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:30101-00-40-10-02-05

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:1 m

Weight:0.323 kg

Views:47

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-40-10-02-05 is a high-performance component of the 3300 XL 8mm Proximity Transducer System, widely recognized in the industrial world for its precision in measuring shaft vibration and position. Manufactured by Bently Nevada, a trusted brand under Baker Hughes, this proximity probe is part of an advanced non-contact measurement system using eddy current technology to monitor rotating machinery in real time.

This probe is typically paired with a matching extension cable and proximity sensor (proximitor) to complete the transducer system. The 330101-00-40-10-02-05 variant offers enhanced signal fidelity and robust construction for installation in harsh environments. It is designed with a 1.0 meter cable length and features a rugged stainless-steel casing for long-term durability in critical machinery monitoring applications.

Product Specifications

| Parameter | Specification |

|---|---|

| Part Number | 330101-00-40-10-02-05 |

| System Compatibility | Bently Nevada 3300 XL 8mm Proximity Transducer System |

| Sensing Technology | Eddy Current |

| Sensing Range | 2 mm (80 mils) nominal |

| Linear Range | 0.5 mm to 2.0 mm (20 mils to 80 mils) |

| Probe Tip Diameter | 8 mm |

| Cable Length | 1.0 meter |

| Connector Type | ClickLoc, Special Sealed Stainless-Steel Connector |

| Thread Size | 3/8-24 UNF-2A |

| Operating Temperature | -35°C to +177°C (-31°F to +350°F) |

| Material | Stainless Steel |

| Probe Body Style | Unarmored, Reverse Mount |

| Nominal System Output | 200 mV/mil (7.87 mV/µm) |

| Power Requirements | Supplied via proximitor (external driver) |

| Environmental Protection | IP65 (with proper sealing) |

| Weight | 0.323 kg |

Product Applications

The Bently Nevada 330101-00-40-10-02-05 probe is widely deployed in industrial sectors where real-time monitoring of rotating machinery is critical. It ensures optimal performance, early fault detection, and preventive maintenance.

Key applications include:

-

Steam Turbines – Shaft vibration and position monitoring.

-

Gas Turbines – High-speed rotating component health monitoring.

-

Compressors – Bearing wear and rotor shaft movement detection.

-

Pumps – Mechanical seal and shaft alignment supervision.

-

Motors and Generators – Vibration and thermal expansion tracking.

-

Gearboxes – Detecting misalignment, imbalance, and looseness.

Product Advantages

-

Proven Eddy Current Technology: Delivers reliable and accurate measurements for shaft vibration and displacement monitoring.

-

Enhanced Durability: Stainless-steel probe construction resists corrosion and mechanical wear in aggressive industrial settings.

-

ClickLoc Connector: Secure and user-friendly connection system minimizes risk of accidental disconnects.

-

Broad Operating Temperature: Wide temperature tolerance supports applications in both hot and cold environments.

-

Interchangeable Design: Compatible with other components in the 3300 XL series, enabling modular system expansion or maintenance.

-

High Accuracy and Stability: Minimal drift over time, reducing recalibration frequency.

-

Custom Length Availability: Probe and cable lengths are available in multiple standard configurations, including 1.0 meter as in this variant.

-

Non-contact Measurement: Eliminates mechanical wear and ensures long-term reliability without physical contact.

-

Industry Trusted: Backed by decades of Bently Nevada field experience in critical machinery protection.

Frequently Asked Questions (FAQ)

-

What is the primary function of the 330101-00-40-10-02-05 probe?

-

It measures shaft vibration and position using non-contact eddy current technology.

-

-

What kind of equipment is it typically used with?

-

Rotating machinery such as turbines, compressors, motors, and pumps.

-

-

Is this probe compatible with other Bently Nevada systems?

-

Yes, it is part of the 3300 XL system and compatible with matched proximitor and extension cables.

-

-

What is the sensing range of this probe?

-

The probe provides a linear sensing range of 0.5 mm to 2.0 mm.

-

-

What material is used for the probe housing?

-

Stainless steel, offering durability and resistance to harsh environments.

-

-

Does this model have a ClickLoc connector?

-

Yes, it features a secure ClickLoc connector to ensure tight and vibration-resistant connections.

-

-

What is the output signal of this probe system?

-

It provides a system output of 200 mV/mil or approximately 7.87 mV/μm.

-

-

What cable length does this specific model provide?

-

It includes a 1.0 meter integral cable.

-

-

Can this probe be used in hazardous environments?

-

It is commonly used in rugged and hazardous environments when paired with proper protective equipment and certifications.

-

-

Is the probe tip replaceable?

-

No, the probe tip is not user-replaceable. Full replacement is recommended in case of tip damage.

Bently Nevada 330101-00-40-10-02-05 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:30101-00-40-10-02-05

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:1 m

Weight:0.323 kg

Views:47

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-00-40-10-02-05 is a high-performance component of the 3300 XL 8mm Proximity Transducer System, widely recognized in the industrial world for its precision in measuring shaft vibration and position. Manufactured by Bently Nevada, a trusted brand under Baker Hughes, this proximity probe is part of an advanced non-contact measurement system using eddy current technology to monitor rotating machinery in real time.

This probe is typically paired with a matching extension cable and proximity sensor (proximitor) to complete the transducer system. The 330101-00-40-10-02-05 variant offers enhanced signal fidelity and robust construction for installation in harsh environments. It is designed with a 1.0 meter cable length and features a rugged stainless-steel casing for long-term durability in critical machinery monitoring applications.

Product Specifications

| Parameter | Specification |

|---|---|

| Part Number | 330101-00-40-10-02-05 |

| System Compatibility | Bently Nevada 3300 XL 8mm Proximity Transducer System |

| Sensing Technology | Eddy Current |

| Sensing Range | 2 mm (80 mils) nominal |

| Linear Range | 0.5 mm to 2.0 mm (20 mils to 80 mils) |

| Probe Tip Diameter | 8 mm |

| Cable Length | 1.0 meter |

| Connector Type | ClickLoc, Special Sealed Stainless-Steel Connector |

| Thread Size | 3/8-24 UNF-2A |

| Operating Temperature | -35°C to +177°C (-31°F to +350°F) |

| Material | Stainless Steel |

| Probe Body Style | Unarmored, Reverse Mount |

| Nominal System Output | 200 mV/mil (7.87 mV/µm) |

| Power Requirements | Supplied via proximitor (external driver) |

| Environmental Protection | IP65 (with proper sealing) |

| Weight | 0.323 kg |

Product Applications

The Bently Nevada 330101-00-40-10-02-05 probe is widely deployed in industrial sectors where real-time monitoring of rotating machinery is critical. It ensures optimal performance, early fault detection, and preventive maintenance.

Key applications include:

-

Steam Turbines – Shaft vibration and position monitoring.

-

Gas Turbines – High-speed rotating component health monitoring.

-

Compressors – Bearing wear and rotor shaft movement detection.

-

Pumps – Mechanical seal and shaft alignment supervision.

-

Motors and Generators – Vibration and thermal expansion tracking.

-

Gearboxes – Detecting misalignment, imbalance, and looseness.

Product Advantages

-

Proven Eddy Current Technology: Delivers reliable and accurate measurements for shaft vibration and displacement monitoring.

-

Enhanced Durability: Stainless-steel probe construction resists corrosion and mechanical wear in aggressive industrial settings.

-

ClickLoc Connector: Secure and user-friendly connection system minimizes risk of accidental disconnects.

-

Broad Operating Temperature: Wide temperature tolerance supports applications in both hot and cold environments.

-

Interchangeable Design: Compatible with other components in the 3300 XL series, enabling modular system expansion or maintenance.

-

High Accuracy and Stability: Minimal drift over time, reducing recalibration frequency.

-

Custom Length Availability: Probe and cable lengths are available in multiple standard configurations, including 1.0 meter as in this variant.

-

Non-contact Measurement: Eliminates mechanical wear and ensures long-term reliability without physical contact.

-

Industry Trusted: Backed by decades of Bently Nevada field experience in critical machinery protection.

Frequently Asked Questions (FAQ)

-

What is the primary function of the 330101-00-40-10-02-05 probe?

-

It measures shaft vibration and position using non-contact eddy current technology.

-

-

What kind of equipment is it typically used with?

-

Rotating machinery such as turbines, compressors, motors, and pumps.

-

-

Is this probe compatible with other Bently Nevada systems?

-

Yes, it is part of the 3300 XL system and compatible with matched proximitor and extension cables.

-

-

What is the sensing range of this probe?

-

The probe provides a linear sensing range of 0.5 mm to 2.0 mm.

-

-

What material is used for the probe housing?

-

Stainless steel, offering durability and resistance to harsh environments.

-

-

Does this model have a ClickLoc connector?

-

Yes, it features a secure ClickLoc connector to ensure tight and vibration-resistant connections.

-

-

What is the output signal of this probe system?

-

It provides a system output of 200 mV/mil or approximately 7.87 mV/μm.

-

-

What cable length does this specific model provide?

-

It includes a 1.0 meter integral cable.

-

-

Can this probe be used in hazardous environments?

-

It is commonly used in rugged and hazardous environments when paired with proper protective equipment and certifications.

-

-

Is the probe tip replaceable?

-

No, the probe tip is not user-replaceable. Full replacement is recommended in case of tip damage.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...