Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

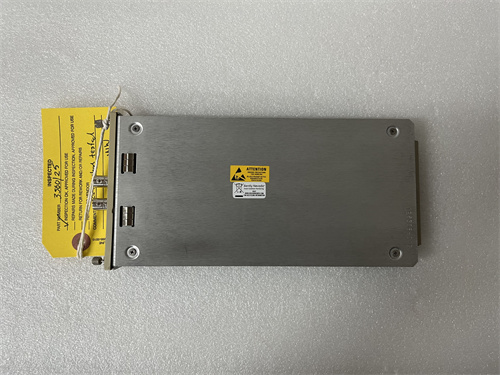

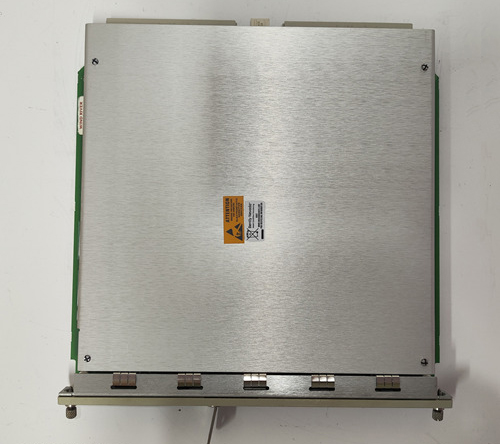

Bently Nevada 330162-01-80-80-05-05-94-01-02 Single Triaxial HP Feedthrough for 3300 System

Manufacturer:Bently Nevada

Product Number:330162-01-80-80-05-05-94-01-02

Product Type:Single Triaxial HP Feedthrough for 3300 System

Origin:USA

Length Option:8 meters

Shipping Weight:3 kg

Views:133

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330162-01-80-80-05-05-94-01-02 Single Triaxial HP Feedthrough is an advanced feedthrough component specifically engineered for the Bently Nevada 3300 system. It provides a reliable interface for transmitting vibration and displacement signals from triaxial sensor probes into monitoring electronics without loss of accuracy or signal degradation.

This model is part of the high-pressure (HP) feedthrough series, designed to withstand harsh mechanical, thermal, and environmental stress conditions. The triaxial capability allows the feedthrough to transmit three-axis vibration measurements simultaneously, ensuring detailed diagnostics of rotating machinery behavior. Its rugged stainless-steel housing, hermetic sealing, and noise-immune design make it ideal for demanding applications such as turbines, compressors, motors, and generators where system reliability is paramount.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 330162-01-80-80-05-05-94-01-02 |

| Type | Single Triaxial HP Feedthrough |

| Compatible System | Bently Nevada 3300 Monitoring System |

| Signal Support | Triaxial vibration and displacement sensor signals |

| Connector Type | Hermetically sealed precision connectors |

| Housing Material | Stainless Steel |

| Insulation | High-grade dielectric for EMI resistance |

| Environmental Protection | High-pressure and vacuum-rated construction |

| Operating Temperature Range | -40°C to +125°C |

| Length Option | 8 meters |

| Shipping Weight | 3 kg |

Applications

The 330162-01-80-80-05-05-94-01-02 feedthrough supports precision condition monitoring in high-value machinery. Its applications include:

Gas and Steam Turbines: Delivers accurate triaxial vibration data to prevent critical failures.

Compressors: Ensures reliable monitoring of multi-axis vibration to detect instability and surge.

Motors and Generators: Provides predictive maintenance insights by capturing shaft and casing vibration.

Vacuum and High-Pressure Systems: Maintains leak-free performance in sealed environments.

Petrochemical Industry: Operates reliably in environments exposed to aggressive chemicals.

Industrial Protection Systems: Integrates with the 3300 system to support shutdown logic for machinery safety.

Advantages

Triaxial Signal Capability: Enables simultaneous monitoring of vibration across three axes for comprehensive diagnostics.

High-Pressure Sealing: Hermetically sealed construction prevents leaks in pressurized or vacuum conditions.

Superior Signal Integrity: Uses high-grade dielectric insulation to minimize electromagnetic interference.

Robust Materials: Stainless steel housing provides strength, corrosion resistance, and long-term stability.

Seamless System Integration: Fully compatible with Bently Nevada 3300 monitoring platforms.

Wide Environmental Range: Performs reliably across extreme temperatures and mechanical stresses.

Long-Term Reliability: Engineered for continuous operation with minimal degradation.

Operational Safety: Enhances machinery protection systems by ensuring accurate signal transmission.

FAQ

Which monitoring systems are supported by this feedthrough?

It is designed for compatibility with the Bently Nevada 3300 monitoring system.

What type of signals does it transmit?

It transmits triaxial vibration and displacement sensor signals with high accuracy.

Is this feedthrough hermetically sealed?

Yes, it is hermetically sealed to prevent leaks in high-pressure and vacuum systems.

How does it reduce electromagnetic interference?

The feedthrough uses high-grade dielectric insulation and shielding to block external noise.

Can this feedthrough be used in high-vibration environments?

Yes, it is mechanically rugged and specifically designed for use in rotating machinery.

What is the operating temperature range?

It operates reliably between -40°C and +125°C.

Is it suitable for triaxial probes only?

It is optimized for triaxial probes but can also support single-axis probes if needed.

Why is it rated for high-pressure use?

The design includes pressure-resistant housing and hermetic sealing for secure operation.

Can it be used in vacuum conditions?

Yes, the sealed construction ensures performance under vacuum without leakage.

Does stainless-steel housing affect electrical performance?

No, stainless steel provides durability while maintaining excellent signal transmission quality.

Bently Nevada 330162-01-80-80-05-05-94-01-02 Single Triaxial HP Feedthrough for 3300 System

Manufacturer:Bently Nevada

Product Number:330162-01-80-80-05-05-94-01-02

Product Type:Single Triaxial HP Feedthrough for 3300 System

Origin:USA

Length Option:8 meters

Shipping Weight:3 kg

Views:133

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330162-01-80-80-05-05-94-01-02 Single Triaxial HP Feedthrough is an advanced feedthrough component specifically engineered for the Bently Nevada 3300 system. It provides a reliable interface for transmitting vibration and displacement signals from triaxial sensor probes into monitoring electronics without loss of accuracy or signal degradation.

This model is part of the high-pressure (HP) feedthrough series, designed to withstand harsh mechanical, thermal, and environmental stress conditions. The triaxial capability allows the feedthrough to transmit three-axis vibration measurements simultaneously, ensuring detailed diagnostics of rotating machinery behavior. Its rugged stainless-steel housing, hermetic sealing, and noise-immune design make it ideal for demanding applications such as turbines, compressors, motors, and generators where system reliability is paramount.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 330162-01-80-80-05-05-94-01-02 |

| Type | Single Triaxial HP Feedthrough |

| Compatible System | Bently Nevada 3300 Monitoring System |

| Signal Support | Triaxial vibration and displacement sensor signals |

| Connector Type | Hermetically sealed precision connectors |

| Housing Material | Stainless Steel |

| Insulation | High-grade dielectric for EMI resistance |

| Environmental Protection | High-pressure and vacuum-rated construction |

| Operating Temperature Range | -40°C to +125°C |

| Length Option | 8 meters |

| Shipping Weight | 3 kg |

Applications

The 330162-01-80-80-05-05-94-01-02 feedthrough supports precision condition monitoring in high-value machinery. Its applications include:

Gas and Steam Turbines: Delivers accurate triaxial vibration data to prevent critical failures.

Compressors: Ensures reliable monitoring of multi-axis vibration to detect instability and surge.

Motors and Generators: Provides predictive maintenance insights by capturing shaft and casing vibration.

Vacuum and High-Pressure Systems: Maintains leak-free performance in sealed environments.

Petrochemical Industry: Operates reliably in environments exposed to aggressive chemicals.

Industrial Protection Systems: Integrates with the 3300 system to support shutdown logic for machinery safety.

Advantages

Triaxial Signal Capability: Enables simultaneous monitoring of vibration across three axes for comprehensive diagnostics.

High-Pressure Sealing: Hermetically sealed construction prevents leaks in pressurized or vacuum conditions.

Superior Signal Integrity: Uses high-grade dielectric insulation to minimize electromagnetic interference.

Robust Materials: Stainless steel housing provides strength, corrosion resistance, and long-term stability.

Seamless System Integration: Fully compatible with Bently Nevada 3300 monitoring platforms.

Wide Environmental Range: Performs reliably across extreme temperatures and mechanical stresses.

Long-Term Reliability: Engineered for continuous operation with minimal degradation.

Operational Safety: Enhances machinery protection systems by ensuring accurate signal transmission.

FAQ

Which monitoring systems are supported by this feedthrough?

It is designed for compatibility with the Bently Nevada 3300 monitoring system.

What type of signals does it transmit?

It transmits triaxial vibration and displacement sensor signals with high accuracy.

Is this feedthrough hermetically sealed?

Yes, it is hermetically sealed to prevent leaks in high-pressure and vacuum systems.

How does it reduce electromagnetic interference?

The feedthrough uses high-grade dielectric insulation and shielding to block external noise.

Can this feedthrough be used in high-vibration environments?

Yes, it is mechanically rugged and specifically designed for use in rotating machinery.

What is the operating temperature range?

It operates reliably between -40°C and +125°C.

Is it suitable for triaxial probes only?

It is optimized for triaxial probes but can also support single-axis probes if needed.

Why is it rated for high-pressure use?

The design includes pressure-resistant housing and hermetic sealing for secure operation.

Can it be used in vacuum conditions?

Yes, the sealed construction ensures performance under vacuum without leakage.

Does stainless-steel housing affect electrical performance?

No, stainless steel provides durability while maintaining excellent signal transmission quality.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...