Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

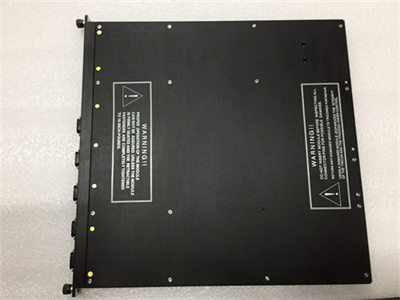

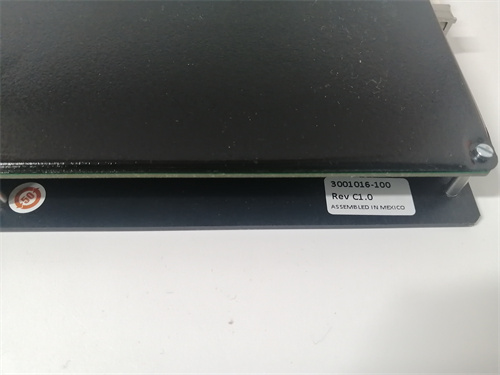

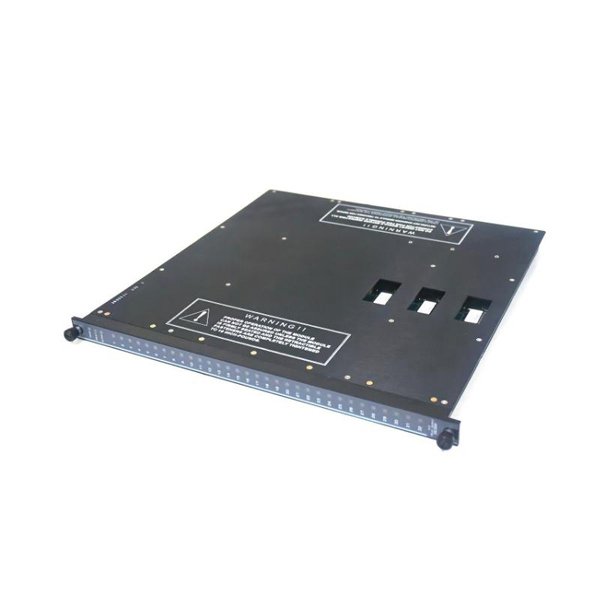

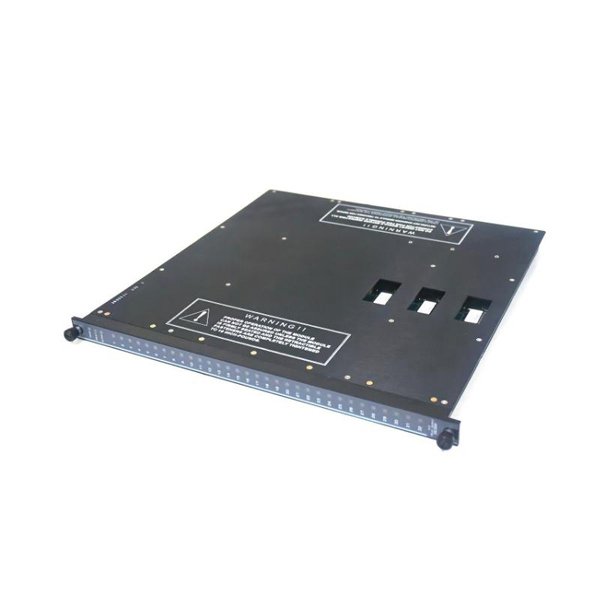

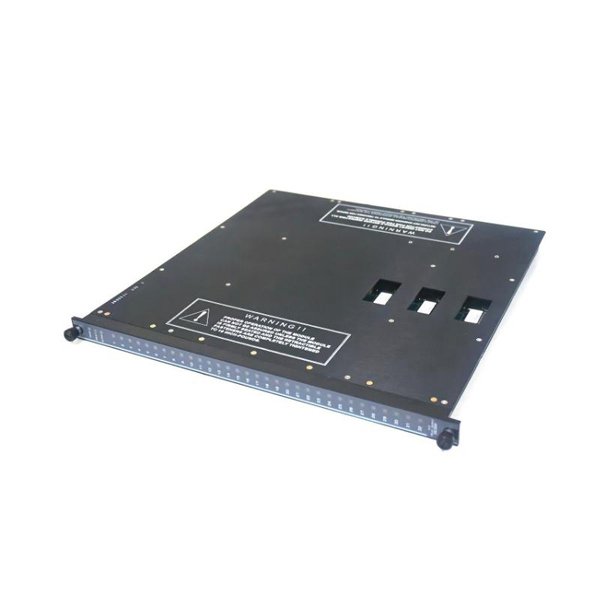

Triconex 3636R Relay Output Module

Manufacturer:Triconex

Product Number:3636R

Product Type:Relay Output Module

Origin:USA

Dimensions:490 x 453 x 68 mm

Weight:1.26 kg

Views:59

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

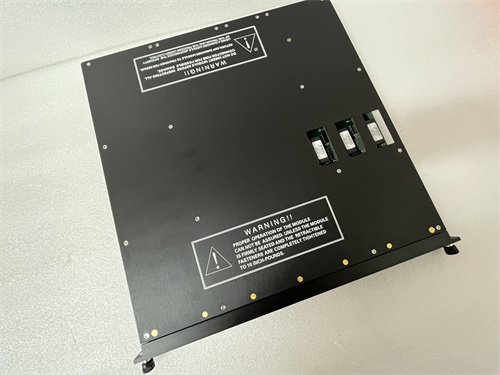

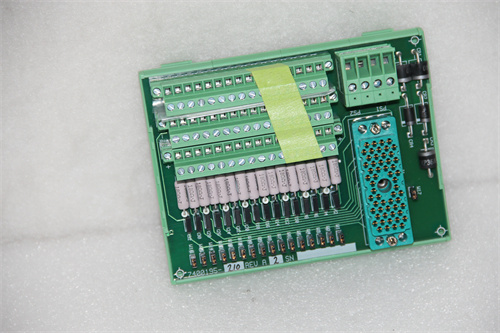

The Triconex 3636R Relay Output Module is a high-performance 32-channel relay output module designed for use in safety-critical automation systems, particularly within the Triconex Tricon™ fault-tolerant safety platform developed by Schneider Electric. This model is engineered to provide redundant output capability, enhancing system availability and integrity in Safety Instrumented Systems (SIS) that demand uninterrupted operation and fail-safe behavior.

Designed for SIL 3 applications according to IEC 61508, the 3636R provides isolated Form A (normally open) relay outputs with mechanical switching, ideal for interfacing with discrete field devices such as solenoids, contactors, ESD valves, and alarms. It ensures safe state behavior under fault conditions, making it an excellent choice for emergency shutdown (ESD), fire and gas (F&G), and critical control systems.

As part of the Triconex ecosystem, it offers hot-replaceability, built-in diagnostics, and compatibility with Triple Modular Redundancy (TMR) architecture.

Product Specifications

| Parameter | Details |

|---|---|

| Model | Triconex 3636R |

| Product Type | Redundant Relay Output Module |

| Channels | 32 isolated relay output channels |

| Relay Type | Form A (SPST-NO), dry contact mechanical relays |

| Output Redundancy | Dual coil redundant output channels |

| Rated Load (Per Channel) | 2 A @ 30 VDC / 2 A @ 250 VAC resistive |

| Contact Life (Nominal) | 5 million operations (no load), 100,000 (full load) |

| Switching Time | <10 ms (typical) |

| Isolation | 2500 Vrms (channel-to-channel and to ground) |

| Diagnostics | Built-in self-test, coil monitoring, watchdog timer |

| Status Indicators | Channel-specific LEDs |

| Hot-Swap Capability | Yes |

| Operating Voltage | Supplied via system backplane |

| Power Consumption | Approx. 7.0 W |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% RH non-condensing |

| Shock & Vibration | Meets IEC 60068-2 standards |

| Mounting | Standard Tricon chassis backplane |

| Dimensions (L × W × H) | 490 x 453 x 68 mm |

| Weight | 1.26 kg |

| Certifications | IEC 61508 SIL 3, ATEX Zone 2, CE, CSA, FM |

Product Applications

The Triconex 3636R module is utilized in hazardous and high-availability industrial environments. Its reliability and redundancy features make it a preferred choice in:

Oil & Gas Platforms: Emergency valve shutdowns, critical alarm signaling, and wellhead controls.

Chemical Processing Plants: Reactor trips, relief valve actuation, and safe interlocking.

Refineries: Compressor and turbine control shutdown logic.

Nuclear and Fossil Power Plants: Isolation valve actuation, safety interlocks, and fire protection systems.

Pharmaceutical Industry: Fail-safe outputs for reactor controls and ventilation systems.

Pulp and Paper Mills: Boiler trip systems and combustion safety shutdowns.

These application environments demand zero downtime, fault tolerance, and guaranteed safe-state behavior—areas where the 3636R excels without compromise.

Product Advantages

True Redundancy Per Channel: Each output channel features dual relay coils to ensure operational continuity in the event of single component failure.

SIL 3 Certified Reliability: Fully compliant with IEC 61508 standards, suitable for the most critical safety loops.

Fail-Safe Architecture: Outputs default to a known safe state in case of power or logic failure.

Mechanical Isolation: Galvanically isolated outputs prevent feedback and reduce noise and fault propagation.

Built-In Diagnostics: Continuous relay coil monitoring and self-test capabilities minimize undetected failure risks.

Fast Switching Performance: Under 10 ms actuation ensures timely system response during emergency scenarios.

Clear Status Indication: Each channel includes an LED indicator for real-time output status feedback.

Robust Environmental Compliance: Operates in wide temperature and humidity ranges with high vibration tolerance.

Hot-Swappable Design: Simplifies maintenance procedures and supports online module replacement.

Optimized for TMR Architecture: Seamlessly integrates with Tricon’s triple redundant system backbone.

FAQ

What differentiates the 3636R from the 3636A module?

The 3636R offers redundant relay coils per channel, whereas the 3636A is a standard single-coil relay output module.

Can the 3636R be used in SIL 3 safety applications?

Yes, the module is fully certified for SIL 3 use under IEC 61508.

Is each output isolated from the others?

Yes, all 32 channels are individually galvanically isolated to prevent crosstalk and shared faults.

Can the module be replaced without shutting down the system?

Absolutely, the 3636R supports hot-swapping via Tricon backplane.

What types of loads can it switch?

It is suitable for resistive and low-inductive loads up to 2 A at 30 VDC or 250 VAC.

How is redundancy achieved on the module?

Each relay output has dual coil control, ensuring that if one fails, the other maintains operability.

Is there a built-in monitoring system?

Yes, the module has coil diagnostics, loop monitoring, and watchdog timers for fault detection.

How many operations can the relays handle?

Relays are rated for up to 5 million no-load or 100,000 full-load operations.

What happens if the module loses power or fails?

The outputs will fail to a pre-defined safe state, ensuring continued protection.

What is the environmental tolerance of the module?

The module operates between -20°C and +60°C and is compliant with industrial shock, vibration, and humidity standards.

Triconex 3636R Relay Output Module

Manufacturer:Triconex

Product Number:3636R

Product Type:Relay Output Module

Origin:USA

Dimensions:490 x 453 x 68 mm

Weight:1.26 kg

Views:59

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Triconex 3636R Relay Output Module is a high-performance 32-channel relay output module designed for use in safety-critical automation systems, particularly within the Triconex Tricon™ fault-tolerant safety platform developed by Schneider Electric. This model is engineered to provide redundant output capability, enhancing system availability and integrity in Safety Instrumented Systems (SIS) that demand uninterrupted operation and fail-safe behavior.

Designed for SIL 3 applications according to IEC 61508, the 3636R provides isolated Form A (normally open) relay outputs with mechanical switching, ideal for interfacing with discrete field devices such as solenoids, contactors, ESD valves, and alarms. It ensures safe state behavior under fault conditions, making it an excellent choice for emergency shutdown (ESD), fire and gas (F&G), and critical control systems.

As part of the Triconex ecosystem, it offers hot-replaceability, built-in diagnostics, and compatibility with Triple Modular Redundancy (TMR) architecture.

Product Specifications

| Parameter | Details |

|---|---|

| Model | Triconex 3636R |

| Product Type | Redundant Relay Output Module |

| Channels | 32 isolated relay output channels |

| Relay Type | Form A (SPST-NO), dry contact mechanical relays |

| Output Redundancy | Dual coil redundant output channels |

| Rated Load (Per Channel) | 2 A @ 30 VDC / 2 A @ 250 VAC resistive |

| Contact Life (Nominal) | 5 million operations (no load), 100,000 (full load) |

| Switching Time | <10 ms (typical) |

| Isolation | 2500 Vrms (channel-to-channel and to ground) |

| Diagnostics | Built-in self-test, coil monitoring, watchdog timer |

| Status Indicators | Channel-specific LEDs |

| Hot-Swap Capability | Yes |

| Operating Voltage | Supplied via system backplane |

| Power Consumption | Approx. 7.0 W |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% RH non-condensing |

| Shock & Vibration | Meets IEC 60068-2 standards |

| Mounting | Standard Tricon chassis backplane |

| Dimensions (L × W × H) | 490 x 453 x 68 mm |

| Weight | 1.26 kg |

| Certifications | IEC 61508 SIL 3, ATEX Zone 2, CE, CSA, FM |

Product Applications

The Triconex 3636R module is utilized in hazardous and high-availability industrial environments. Its reliability and redundancy features make it a preferred choice in:

Oil & Gas Platforms: Emergency valve shutdowns, critical alarm signaling, and wellhead controls.

Chemical Processing Plants: Reactor trips, relief valve actuation, and safe interlocking.

Refineries: Compressor and turbine control shutdown logic.

Nuclear and Fossil Power Plants: Isolation valve actuation, safety interlocks, and fire protection systems.

Pharmaceutical Industry: Fail-safe outputs for reactor controls and ventilation systems.

Pulp and Paper Mills: Boiler trip systems and combustion safety shutdowns.

These application environments demand zero downtime, fault tolerance, and guaranteed safe-state behavior—areas where the 3636R excels without compromise.

Product Advantages

True Redundancy Per Channel: Each output channel features dual relay coils to ensure operational continuity in the event of single component failure.

SIL 3 Certified Reliability: Fully compliant with IEC 61508 standards, suitable for the most critical safety loops.

Fail-Safe Architecture: Outputs default to a known safe state in case of power or logic failure.

Mechanical Isolation: Galvanically isolated outputs prevent feedback and reduce noise and fault propagation.

Built-In Diagnostics: Continuous relay coil monitoring and self-test capabilities minimize undetected failure risks.

Fast Switching Performance: Under 10 ms actuation ensures timely system response during emergency scenarios.

Clear Status Indication: Each channel includes an LED indicator for real-time output status feedback.

Robust Environmental Compliance: Operates in wide temperature and humidity ranges with high vibration tolerance.

Hot-Swappable Design: Simplifies maintenance procedures and supports online module replacement.

Optimized for TMR Architecture: Seamlessly integrates with Tricon’s triple redundant system backbone.

FAQ

What differentiates the 3636R from the 3636A module?

The 3636R offers redundant relay coils per channel, whereas the 3636A is a standard single-coil relay output module.

Can the 3636R be used in SIL 3 safety applications?

Yes, the module is fully certified for SIL 3 use under IEC 61508.

Is each output isolated from the others?

Yes, all 32 channels are individually galvanically isolated to prevent crosstalk and shared faults.

Can the module be replaced without shutting down the system?

Absolutely, the 3636R supports hot-swapping via Tricon backplane.

What types of loads can it switch?

It is suitable for resistive and low-inductive loads up to 2 A at 30 VDC or 250 VAC.

How is redundancy achieved on the module?

Each relay output has dual coil control, ensuring that if one fails, the other maintains operability.

Is there a built-in monitoring system?

Yes, the module has coil diagnostics, loop monitoring, and watchdog timers for fault detection.

How many operations can the relays handle?

Relays are rated for up to 5 million no-load or 100,000 full-load operations.

What happens if the module loses power or fails?

The outputs will fail to a pre-defined safe state, ensuring continued protection.

What is the environmental tolerance of the module?

The module operates between -20°C and +60°C and is compliant with industrial shock, vibration, and humidity standards.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...