Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

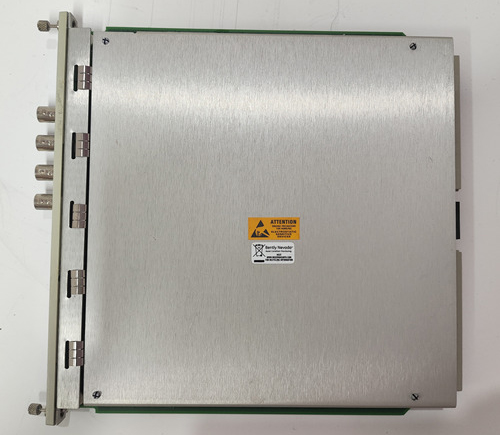

Bently Nevada 330105-02-12-15-12-CN 3300 XL 8mm Reverse Mount Proximity Probe

Manufacturer:Bently Nevada

Product Number:330105-02-12-15-12-CN

Product Type:3300 XL 8mm Reverse Mount Proximity Probe

Origin:USA

Total Length:1.5 meter

Weight:0.485kg

Views:28

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330105-02-12-15-12-CN is a precision 8mm reverse mount proximity probe from the Bently Nevada 3300 XL series, designed for precise vibration and displacement measurements in rotating machinery. This probe is ideal for applications requiring accurate and reliable condition monitoring of critical equipment such as turbines, motors, compressors, and pumps in various industries.

The 330105-02-12-15-12-CN model features a reverse mount design, allowing it to be installed in space-constrained environments where traditional mounting configurations are not feasible. It is engineered to provide high-performance monitoring in industrial conditions, including those that involve heavy machinery or high-vibration environments.

By utilizing eddy current sensing technology, the probe provides highly accurate readings, minimizing the risk of interference and ensuring that the data is reliable for decision-making. It is designed to operate seamlessly within the Bently Nevada 3300 XL system, which is known for its flexibility, scalability, and easy integration into various industrial setups.

Whether monitoring rotating machinery in oil and gas, power generation, mining, or manufacturing, this probe helps improve asset management, optimize maintenance schedules, and prevent unplanned downtime.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | 330105-02-12-15-12-CN |

| Probe Type | 8mm Reverse Mount Proximity Probe |

| Total Length | 1.5 meter |

| Weight | 0.485 kg |

| Measurement Range | ±5.0 mm |

| Operating Temperature | -40°C to +120°C |

| Cable Length | 1.5 meter |

| Mounting Style | Reverse mount for tight installations |

| Output Signal | 4-20 mA (depending on system configuration) |

| Sensing Element | Eddy current principle for precise measurements |

| Compliance | CE, UL, ATEX, IECEx certified |

| Application | Vibration and displacement monitoring |

| Connector Type | Lemo or equivalent (compatible with Bently Nevada systems) |

Applications

The Bently Nevada 330105-02-12-15-12-CN 8mm reverse mount proximity probe is widely used in industries where continuous monitoring of critical machinery is essential. Some key applications include:

Power Generation: Monitoring turbines, generators, and compressors to prevent failure and optimize maintenance schedules.

Oil and Gas: Ensuring the proper functioning of pumps, compressors, turbines, and other critical equipment in upstream and downstream operations.

Mining and Heavy Industry: Used for monitoring crushers, mills, conveyors, and other machinery in mining and mineral processing plants.

Manufacturing: Ensuring efficient operation of motors, pumps, and other rotating machinery in factories and industrial plants.

Water Treatment: Provides real-time monitoring of critical pumps, valves, and motors in water and wastewater treatment facilities.

Transportation: Used in transportation systems, including railways and automated machinery, to monitor the performance of rotating components.

The reverse mount design is especially beneficial in applications where space is limited, allowing easy installation without compromising performance.

Key Advantages

Precision and Reliability: The 330105-02-12-15-12-CN probe provides highly accurate displacement and vibration measurements, critical for detecting early signs of machinery failure and reducing downtime.

Space-Efficient Design: The reverse mount design allows for installation in tight spaces, where traditional probe mounting is not feasible, making it ideal for challenging environments.

Eddy Current Sensing Technology: Using eddy current sensing technology, this probe delivers accurate, interference-free measurements, even in electrically noisy industrial environments.

Durable and Long-Lasting: The probe is built to last with robust materials that ensure reliable performance and durability in harsh conditions.

Wide Temperature Range: It operates effectively within a temperature range of -40°C to +120°C, making it suitable for both freezing and high-heat environments.

Real-Time Monitoring: The probe provides continuous, real-time data, enabling proactive monitoring of machinery and preventing catastrophic failures.

Compact and Lightweight: With a 1.5 meter cable and 0.485 kg weight, the probe is compact and easy to handle while still offering high measurement accuracy.

International Certification: Certified with CE, UL, ATEX, and IECEx, ensuring the probe meets safety standards for use in hazardous and explosive environments.

Versatile Integration: The probe is compatible with other Bently Nevada monitoring systems, allowing easy integration into existing setups.

Low Maintenance: The design and construction of the probe minimize the need for frequent maintenance, providing a reliable and cost-effective solution for continuous monitoring.

Frequently Asked Questions (FAQ)

What is the total length of the Bently Nevada 330105-02-12-15-12-CN probe?

The total length of the probe is 1.5 meters.

What is the weight of the 3300 XL reverse mount proximity probe?

The probe weighs 0.485 kg.

What sensing technology does the 3300 XL proximity probe use?

The probe uses eddy current sensing technology, ensuring precise and interference-free measurements.

What is the measurement range of the 3300 XL 8mm reverse mount probe?

The measurement range is ±5.0 mm.

What is the operating temperature range of the 3300 XL 8mm probe?

The operating temperature range is -40°C to +120°C.

Can the 3300 XL proximity probe be used in hazardous environments?

Yes, it is certified for use in hazardous environments and complies with ATEX, IECEx, CE, and UL standards.

How does the reverse mount design benefit installations?

The reverse mount design allows for easy installation in tight or limited spaces, providing more flexibility in challenging applications.

What output signal does the 3300 XL 8mm reverse mount probe generate?

The probe typically generates a 4-20 mA output signal, depending on the system configuration.

What types of machinery can the 3300 XL proximity probe monitor?

The probe is used to monitor rotating equipment like turbines, motors, compressors, pumps, and other critical machinery.

Is the 3300 XL 8mm reverse mount probe compatible with other Bently Nevada systems?

Yes, the probe is designed to integrate seamlessly with other Bently Nevada equipment and can be used in various vibration monitoring systems.

Bently Nevada 330105-02-12-15-12-CN 3300 XL 8mm Reverse Mount Proximity Probe

Manufacturer:Bently Nevada

Product Number:330105-02-12-15-12-CN

Product Type:3300 XL 8mm Reverse Mount Proximity Probe

Origin:USA

Total Length:1.5 meter

Weight:0.485kg

Views:28

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330105-02-12-15-12-CN is a precision 8mm reverse mount proximity probe from the Bently Nevada 3300 XL series, designed for precise vibration and displacement measurements in rotating machinery. This probe is ideal for applications requiring accurate and reliable condition monitoring of critical equipment such as turbines, motors, compressors, and pumps in various industries.

The 330105-02-12-15-12-CN model features a reverse mount design, allowing it to be installed in space-constrained environments where traditional mounting configurations are not feasible. It is engineered to provide high-performance monitoring in industrial conditions, including those that involve heavy machinery or high-vibration environments.

By utilizing eddy current sensing technology, the probe provides highly accurate readings, minimizing the risk of interference and ensuring that the data is reliable for decision-making. It is designed to operate seamlessly within the Bently Nevada 3300 XL system, which is known for its flexibility, scalability, and easy integration into various industrial setups.

Whether monitoring rotating machinery in oil and gas, power generation, mining, or manufacturing, this probe helps improve asset management, optimize maintenance schedules, and prevent unplanned downtime.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | 330105-02-12-15-12-CN |

| Probe Type | 8mm Reverse Mount Proximity Probe |

| Total Length | 1.5 meter |

| Weight | 0.485 kg |

| Measurement Range | ±5.0 mm |

| Operating Temperature | -40°C to +120°C |

| Cable Length | 1.5 meter |

| Mounting Style | Reverse mount for tight installations |

| Output Signal | 4-20 mA (depending on system configuration) |

| Sensing Element | Eddy current principle for precise measurements |

| Compliance | CE, UL, ATEX, IECEx certified |

| Application | Vibration and displacement monitoring |

| Connector Type | Lemo or equivalent (compatible with Bently Nevada systems) |

Applications

The Bently Nevada 330105-02-12-15-12-CN 8mm reverse mount proximity probe is widely used in industries where continuous monitoring of critical machinery is essential. Some key applications include:

Power Generation: Monitoring turbines, generators, and compressors to prevent failure and optimize maintenance schedules.

Oil and Gas: Ensuring the proper functioning of pumps, compressors, turbines, and other critical equipment in upstream and downstream operations.

Mining and Heavy Industry: Used for monitoring crushers, mills, conveyors, and other machinery in mining and mineral processing plants.

Manufacturing: Ensuring efficient operation of motors, pumps, and other rotating machinery in factories and industrial plants.

Water Treatment: Provides real-time monitoring of critical pumps, valves, and motors in water and wastewater treatment facilities.

Transportation: Used in transportation systems, including railways and automated machinery, to monitor the performance of rotating components.

The reverse mount design is especially beneficial in applications where space is limited, allowing easy installation without compromising performance.

Key Advantages

Precision and Reliability: The 330105-02-12-15-12-CN probe provides highly accurate displacement and vibration measurements, critical for detecting early signs of machinery failure and reducing downtime.

Space-Efficient Design: The reverse mount design allows for installation in tight spaces, where traditional probe mounting is not feasible, making it ideal for challenging environments.

Eddy Current Sensing Technology: Using eddy current sensing technology, this probe delivers accurate, interference-free measurements, even in electrically noisy industrial environments.

Durable and Long-Lasting: The probe is built to last with robust materials that ensure reliable performance and durability in harsh conditions.

Wide Temperature Range: It operates effectively within a temperature range of -40°C to +120°C, making it suitable for both freezing and high-heat environments.

Real-Time Monitoring: The probe provides continuous, real-time data, enabling proactive monitoring of machinery and preventing catastrophic failures.

Compact and Lightweight: With a 1.5 meter cable and 0.485 kg weight, the probe is compact and easy to handle while still offering high measurement accuracy.

International Certification: Certified with CE, UL, ATEX, and IECEx, ensuring the probe meets safety standards for use in hazardous and explosive environments.

Versatile Integration: The probe is compatible with other Bently Nevada monitoring systems, allowing easy integration into existing setups.

Low Maintenance: The design and construction of the probe minimize the need for frequent maintenance, providing a reliable and cost-effective solution for continuous monitoring.

Frequently Asked Questions (FAQ)

What is the total length of the Bently Nevada 330105-02-12-15-12-CN probe?

The total length of the probe is 1.5 meters.

What is the weight of the 3300 XL reverse mount proximity probe?

The probe weighs 0.485 kg.

What sensing technology does the 3300 XL proximity probe use?

The probe uses eddy current sensing technology, ensuring precise and interference-free measurements.

What is the measurement range of the 3300 XL 8mm reverse mount probe?

The measurement range is ±5.0 mm.

What is the operating temperature range of the 3300 XL 8mm probe?

The operating temperature range is -40°C to +120°C.

Can the 3300 XL proximity probe be used in hazardous environments?

Yes, it is certified for use in hazardous environments and complies with ATEX, IECEx, CE, and UL standards.

How does the reverse mount design benefit installations?

The reverse mount design allows for easy installation in tight or limited spaces, providing more flexibility in challenging applications.

What output signal does the 3300 XL 8mm reverse mount probe generate?

The probe typically generates a 4-20 mA output signal, depending on the system configuration.

What types of machinery can the 3300 XL proximity probe monitor?

The probe is used to monitor rotating equipment like turbines, motors, compressors, pumps, and other critical machinery.

Is the 3300 XL 8mm reverse mount probe compatible with other Bently Nevada systems?

Yes, the probe is designed to integrate seamlessly with other Bently Nevada equipment and can be used in various vibration monitoring systems.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...