Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

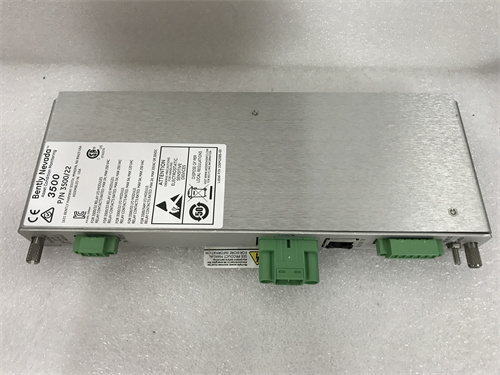

Bently Nevada 330851-03-000-010-10-00-05 3300 XL 25 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330851-03-000-010-10-00-05

Product Type:3300 XL 25 mm Proximity Probe

Origin:USA

Total Length:1m

Weight :0.23 kg

Views:6

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330851-03-000-010-10-00-05 3300 XL 25 mm Proximity Probe is a high-precision vibration and position monitoring sensor specifically designed for heavy-duty industrial rotating machinery. This probe is part of the trusted 3300 XL series, known for delivering consistent and reliable measurements in harsh environments. It works in combination with extension cables and proximity sensor drivers to provide accurate shaft displacement and vibration readings.

Product Parameters

| Parameter | Value |

|---|---|

| Model Number | 330851-03-000-010-10-00-05 |

| Series | 3300 XL |

| Probe Type | 25 mm Proximity Probe |

| Linear Range | 25 mm (1000 mils) |

| Frequency Response | DC to 10 kHz |

| Sensitivity | 200 mV/mil (±5%) |

| Typical System Accuracy | ±0.25 mils or better |

| Operating Temperature | -35 °C to +180 °C |

| Total Length | 1 m |

| Weight | 0.23 kg |

| Connector Type | Standard 3300 XL connector |

| Compliance | API 670, CE certified |

Product Applications

Turbomachinery: Gas turbines, steam turbines, hydro turbines.

Compressors: Centrifugal and reciprocating compressors.

Pumps & Motors: Large industrial pumps and electric drive motors.

Gearboxes: High-speed gearbox condition monitoring.

Generators: Shaft vibration and rotor dynamics monitoring.

Critical process equipment: Machinery requiring API 670 compliance.

Product Advantages

Extended Linear Range: Offers a full 25 mm range, suitable for larger shaft movements compared to standard probes.

High Reliability: Built for long-term operation in extreme conditions, including vibration, high temperatures, and electromagnetic interference.

API 670 Compliance: Meets the stringent requirements for machinery protection systems.

Interchangeable System Components: Fully compatible with 3300 XL extension cables and drivers, simplifying replacement and upgrades.

Stable Output: Consistent sensitivity and accuracy over the entire linear range.

Durability: Resistant to contamination, oil, and industrial environments.

FAQ

Q1: What is the main difference between the 25 mm probe and smaller range probes in the 3300 XL series?

A1: The 25 mm probe provides a larger linear measurement range, making it more suitable for machines with larger shaft movements compared to 8 mm or 11 mm probes.

Q2: Can this probe be directly connected to a monitor without an extension cable?

A2: No, it requires use with the appropriate extension cable and proximity sensor driver to function correctly.

Q3: Is the probe affected by temperature variations during operation?

A3: The probe is designed with compensation to minimize errors, ensuring accurate measurements across its specified temperature range.

Q4: What type of targets can the probe measure effectively?

A4: The probe is optimized for metallic targets, typically high-quality steel shafts as per API 670 standards.

Q5: Does the probe require calibration in the field?

A5: Factory calibration is provided, but system verification during installation is recommended to ensure accuracy.

Q6: Can multiple probes be installed on the same machine shaft?

A6: Yes, multiple probes are commonly used at 90° orientations for vibration and position monitoring.

Q7: What is the output signal format of the probe system?

A7: The probe outputs a voltage proportional to the gap distance, typically 200 mV per mil of shaft displacement.

Q8: How does the probe handle electrical noise in industrial environments?

A8: The 3300 XL series incorporates advanced shielding and grounding to minimize susceptibility to EMI/RFI interference.

Q9: Can the probe be used in hazardous area environments?

A9: Yes, with appropriate system certifications and installation practices, it can be applied in hazardous environments.

Q10: What is the maximum cable length supported in this system?

A10: Depending on configuration, up to 9 meters total length (probe + extension cable) can be used without loss of accuracy.

Bently Nevada 330851-03-000-010-10-00-05 3300 XL 25 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330851-03-000-010-10-00-05

Product Type:3300 XL 25 mm Proximity Probe

Origin:USA

Total Length:1m

Weight :0.23 kg

Views:6

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330851-03-000-010-10-00-05 3300 XL 25 mm Proximity Probe is a high-precision vibration and position monitoring sensor specifically designed for heavy-duty industrial rotating machinery. This probe is part of the trusted 3300 XL series, known for delivering consistent and reliable measurements in harsh environments. It works in combination with extension cables and proximity sensor drivers to provide accurate shaft displacement and vibration readings.

Product Parameters

| Parameter | Value |

|---|---|

| Model Number | 330851-03-000-010-10-00-05 |

| Series | 3300 XL |

| Probe Type | 25 mm Proximity Probe |

| Linear Range | 25 mm (1000 mils) |

| Frequency Response | DC to 10 kHz |

| Sensitivity | 200 mV/mil (±5%) |

| Typical System Accuracy | ±0.25 mils or better |

| Operating Temperature | -35 °C to +180 °C |

| Total Length | 1 m |

| Weight | 0.23 kg |

| Connector Type | Standard 3300 XL connector |

| Compliance | API 670, CE certified |

Product Applications

Turbomachinery: Gas turbines, steam turbines, hydro turbines.

Compressors: Centrifugal and reciprocating compressors.

Pumps & Motors: Large industrial pumps and electric drive motors.

Gearboxes: High-speed gearbox condition monitoring.

Generators: Shaft vibration and rotor dynamics monitoring.

Critical process equipment: Machinery requiring API 670 compliance.

Product Advantages

Extended Linear Range: Offers a full 25 mm range, suitable for larger shaft movements compared to standard probes.

High Reliability: Built for long-term operation in extreme conditions, including vibration, high temperatures, and electromagnetic interference.

API 670 Compliance: Meets the stringent requirements for machinery protection systems.

Interchangeable System Components: Fully compatible with 3300 XL extension cables and drivers, simplifying replacement and upgrades.

Stable Output: Consistent sensitivity and accuracy over the entire linear range.

Durability: Resistant to contamination, oil, and industrial environments.

FAQ

Q1: What is the main difference between the 25 mm probe and smaller range probes in the 3300 XL series?

A1: The 25 mm probe provides a larger linear measurement range, making it more suitable for machines with larger shaft movements compared to 8 mm or 11 mm probes.

Q2: Can this probe be directly connected to a monitor without an extension cable?

A2: No, it requires use with the appropriate extension cable and proximity sensor driver to function correctly.

Q3: Is the probe affected by temperature variations during operation?

A3: The probe is designed with compensation to minimize errors, ensuring accurate measurements across its specified temperature range.

Q4: What type of targets can the probe measure effectively?

A4: The probe is optimized for metallic targets, typically high-quality steel shafts as per API 670 standards.

Q5: Does the probe require calibration in the field?

A5: Factory calibration is provided, but system verification during installation is recommended to ensure accuracy.

Q6: Can multiple probes be installed on the same machine shaft?

A6: Yes, multiple probes are commonly used at 90° orientations for vibration and position monitoring.

Q7: What is the output signal format of the probe system?

A7: The probe outputs a voltage proportional to the gap distance, typically 200 mV per mil of shaft displacement.

Q8: How does the probe handle electrical noise in industrial environments?

A8: The 3300 XL series incorporates advanced shielding and grounding to minimize susceptibility to EMI/RFI interference.

Q9: Can the probe be used in hazardous area environments?

A9: Yes, with appropriate system certifications and installation practices, it can be applied in hazardous environments.

Q10: What is the maximum cable length supported in this system?

A10: Depending on configuration, up to 9 meters total length (probe + extension cable) can be used without loss of accuracy.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...