Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

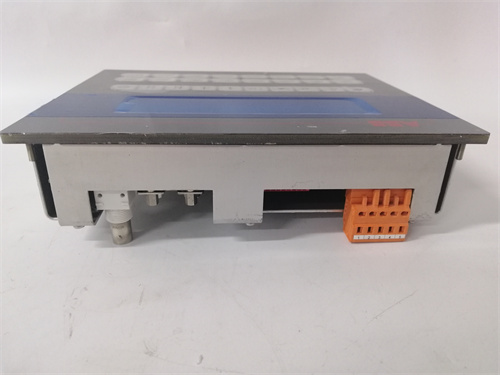

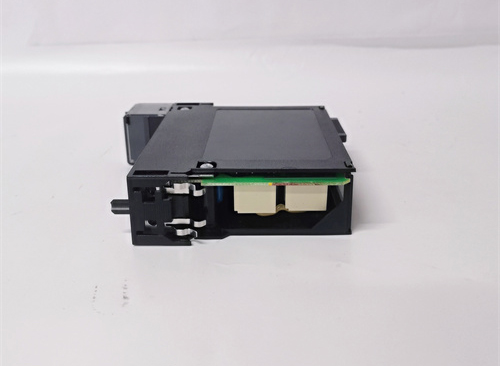

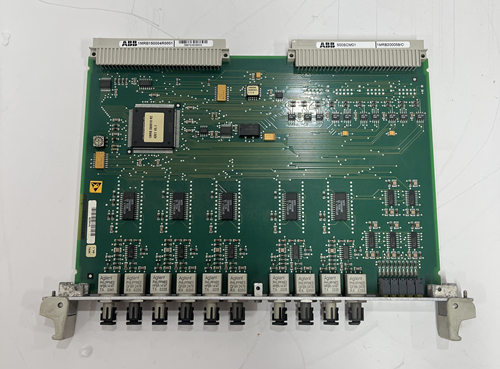

ABB ZINT-541 3AUA0000065896R Interface board Inverter accessories

Manufacturer:ABB

Product Number:ZINT-541 3AUA0000065896R

Condition:Interface board Inverter accessories

Origin:Sweden

Dimensions:90 × 100 × 70 mm

Weight:0.5 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

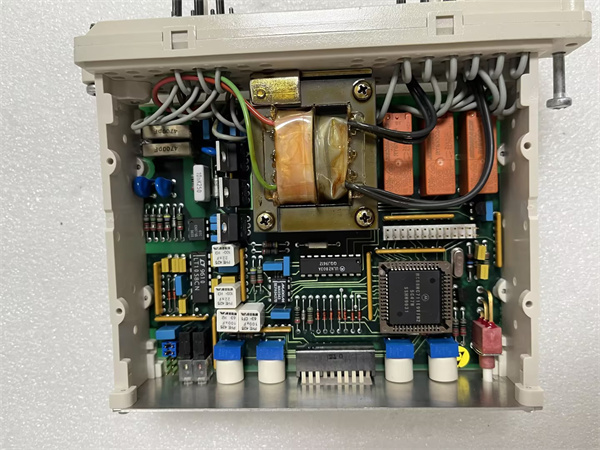

This module is an essential accessory in complex automation environments where reliable drive control and monitoring are crucial. It enhances system interoperability and supports efficient diagnostics, configuration, and data transmission.

Product Advantages

Robust Compatibility: Designed to work seamlessly with ABB ACS800 and ACS880 drive systems.

Protocol Flexibility: Supports multiple industrial protocols including Modbus, Profibus, DeviceNet, and CANopen depending on configuration.

Plug-and-Play Installation: Easy integration and minimal downtime during setup.

Real-Time Communication: Enables fast and reliable data exchange between drive and control system.

Enhanced Diagnostics: Provides valuable fault and performance data to higher-level systems.

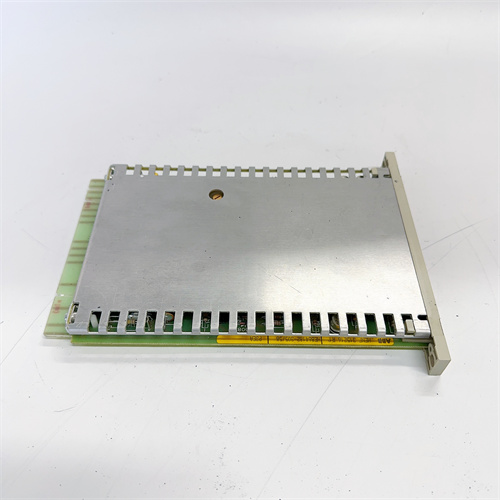

Compact Design: Space-efficient for control cabinets with constrained space.

Long Service Life: Industrial-grade durability ensures extended performance in harsh environments.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | ZINT-541 |

| ABB Part Number | 3AUA0000065896R |

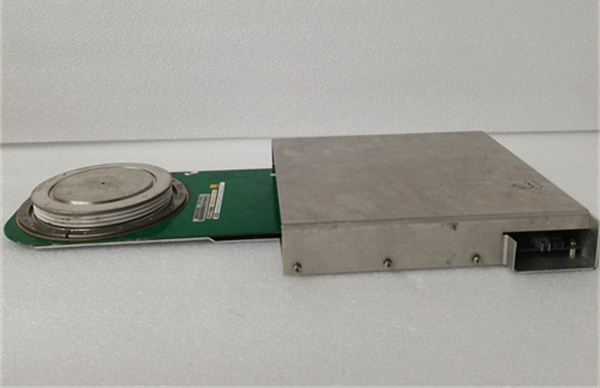

| Product Type | Communication Interface Module |

| Compatible Drive Series | ACS800, ACS880 |

| Supported Protocols | Depending on configuration (e.g., Modbus, Profibus) |

| Power Supply | Supplied from the drive control board |

| Dimensions | 90 × 100 × 70 mm |

| Weight | 0.5 kg |

| Mounting Type | DIN rail or direct mounting inside drive |

| Operating Temperature | -10°C to +55°C |

| Storage Temperature | -40°C to +70°C |

| Certifications | CE, RoHS, UL, cUL |

Product Applications

Industrial Automation Systems: Used for integrating ABB drives into large-scale automation networks.

Manufacturing Plants: Enables communication between drive and factory control infrastructure.

Water Treatment Facilities: Real-time control and monitoring of motors used in pumping systems.

Mining and Metals: Communication between high-power drives and PLCs for ore processing or smelting.

Paper and Pulp Industry: Facilitates smooth operation and diagnostics in drive-intensive environments.

Oil and Gas: Helps integrate ABB drives into hazardous or remote SCADA control systems.

Product Installation Instructions

Ensure Power is Off: Before installation, make sure the drive and control cabinet are powered off.

Mounting the Module: Securely mount the ZINT-541 module inside the drive compartment or on a DIN rail.

Connect Communication Cables: Use appropriate cables depending on the desired protocol (e.g., Profibus, Modbus).

Secure Wiring: Make sure wiring is shielded and grounded as per ABB wiring recommendations.

Configure Protocol Settings: Use the ABB Drive Composer or assistant panels to set communication parameters.

Power On and Test: Restore power, and ensure successful communication handshake with control system.

FAQs (Frequently Asked Questions)

Q1: What is the primary function of the ABB ZINT-541?

A1: It acts as a communication interface module, enabling ABB drives to connect with industrial automation systems.

Q2: Is the ZINT-541 compatible with ACS880 drives?

A2: Yes, it is fully compatible with both ACS800 and ACS880 drive series.

Q3: Does this module support Modbus RTU?

A3: Yes, depending on configuration and setup, it can support Modbus RTU among other protocols.

Q4: How is the module powered?

A4: It receives its power directly from the drive’s internal control board—no external power supply is needed.

Q5: Can it be installed in hazardous locations?

A5: While it’s suitable for industrial environments, for hazardous zones it must be used within an approved enclosure.

Q6: What diagnostic features are supported?

A6: The module supports fault status reporting, real-time data updates, and protocol-specific diagnostics.

Q7: What tools are used for configuration?

A7: Configuration is typically done using ABB’s Drive Composer software or via the drive’s local control panel.

Q8: Is firmware update possible on this module?

A8: Firmware updates may be possible depending on the specific revision and configuration method used.

Q9: How long is the product lifecycle?

A9: Designed for long-term industrial use, ABB estimates over 5 years of reliable operation under standard conditions.

Q10: Can I hot-swap the ZINT-541 during operation?

A10: No, the module should only be installed or removed when the system is powered down to avoid electrical damage.

ABB ZINT-541 3AUA0000065896R Interface board Inverter accessories

Manufacturer:ABB

Product Number:ZINT-541 3AUA0000065896R

Condition:Interface board Inverter accessories

Origin:Sweden

Dimensions:90 × 100 × 70 mm

Weight:0.5 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

This module is an essential accessory in complex automation environments where reliable drive control and monitoring are crucial. It enhances system interoperability and supports efficient diagnostics, configuration, and data transmission.

Product Advantages

Robust Compatibility: Designed to work seamlessly with ABB ACS800 and ACS880 drive systems.

Protocol Flexibility: Supports multiple industrial protocols including Modbus, Profibus, DeviceNet, and CANopen depending on configuration.

Plug-and-Play Installation: Easy integration and minimal downtime during setup.

Real-Time Communication: Enables fast and reliable data exchange between drive and control system.

Enhanced Diagnostics: Provides valuable fault and performance data to higher-level systems.

Compact Design: Space-efficient for control cabinets with constrained space.

Long Service Life: Industrial-grade durability ensures extended performance in harsh environments.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | ZINT-541 |

| ABB Part Number | 3AUA0000065896R |

| Product Type | Communication Interface Module |

| Compatible Drive Series | ACS800, ACS880 |

| Supported Protocols | Depending on configuration (e.g., Modbus, Profibus) |

| Power Supply | Supplied from the drive control board |

| Dimensions | 90 × 100 × 70 mm |

| Weight | 0.5 kg |

| Mounting Type | DIN rail or direct mounting inside drive |

| Operating Temperature | -10°C to +55°C |

| Storage Temperature | -40°C to +70°C |

| Certifications | CE, RoHS, UL, cUL |

Product Applications

Industrial Automation Systems: Used for integrating ABB drives into large-scale automation networks.

Manufacturing Plants: Enables communication between drive and factory control infrastructure.

Water Treatment Facilities: Real-time control and monitoring of motors used in pumping systems.

Mining and Metals: Communication between high-power drives and PLCs for ore processing or smelting.

Paper and Pulp Industry: Facilitates smooth operation and diagnostics in drive-intensive environments.

Oil and Gas: Helps integrate ABB drives into hazardous or remote SCADA control systems.

Product Installation Instructions

Ensure Power is Off: Before installation, make sure the drive and control cabinet are powered off.

Mounting the Module: Securely mount the ZINT-541 module inside the drive compartment or on a DIN rail.

Connect Communication Cables: Use appropriate cables depending on the desired protocol (e.g., Profibus, Modbus).

Secure Wiring: Make sure wiring is shielded and grounded as per ABB wiring recommendations.

Configure Protocol Settings: Use the ABB Drive Composer or assistant panels to set communication parameters.

Power On and Test: Restore power, and ensure successful communication handshake with control system.

FAQs (Frequently Asked Questions)

Q1: What is the primary function of the ABB ZINT-541?

A1: It acts as a communication interface module, enabling ABB drives to connect with industrial automation systems.

Q2: Is the ZINT-541 compatible with ACS880 drives?

A2: Yes, it is fully compatible with both ACS800 and ACS880 drive series.

Q3: Does this module support Modbus RTU?

A3: Yes, depending on configuration and setup, it can support Modbus RTU among other protocols.

Q4: How is the module powered?

A4: It receives its power directly from the drive’s internal control board—no external power supply is needed.

Q5: Can it be installed in hazardous locations?

A5: While it’s suitable for industrial environments, for hazardous zones it must be used within an approved enclosure.

Q6: What diagnostic features are supported?

A6: The module supports fault status reporting, real-time data updates, and protocol-specific diagnostics.

Q7: What tools are used for configuration?

A7: Configuration is typically done using ABB’s Drive Composer software or via the drive’s local control panel.

Q8: Is firmware update possible on this module?

A8: Firmware updates may be possible depending on the specific revision and configuration method used.

Q9: How long is the product lifecycle?

A9: Designed for long-term industrial use, ABB estimates over 5 years of reliable operation under standard conditions.

Q10: Can I hot-swap the ZINT-541 during operation?

A10: No, the module should only be installed or removed when the system is powered down to avoid electrical damage.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...