Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

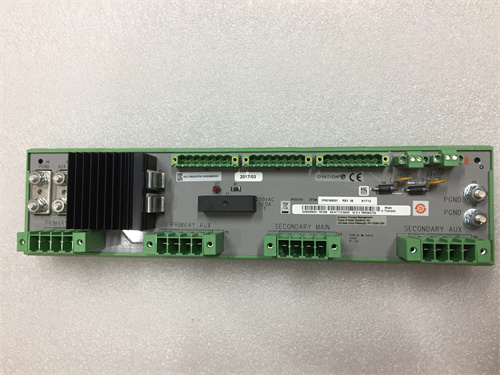

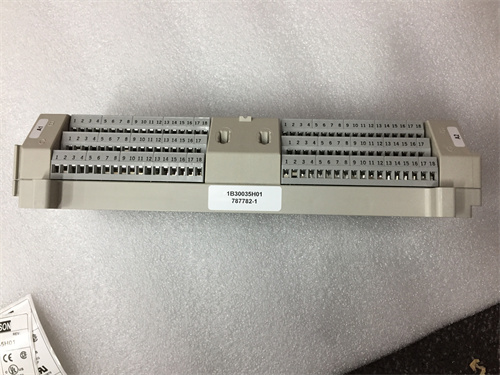

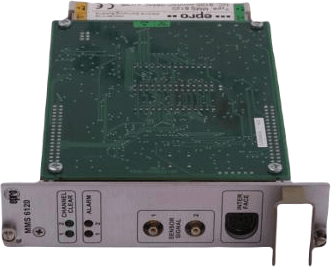

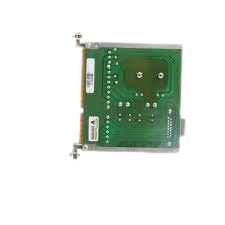

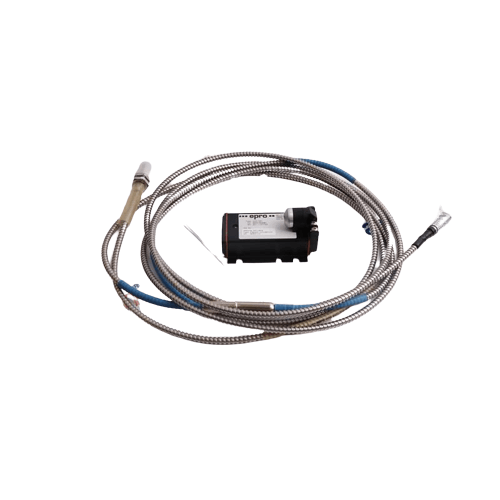

Emerson VE4050E1C0 KJ4001X1-BE1 DeltaV Input Output Carrier

Manufacturer:Emerson

Product Number: VE4050E1C0 KJ4001X1-BE1

Product Type:DeltaV Input Output Carrier

Origin:USA

Dimensions:330 x 140 x 50 mm

Weight :0.689 kg

Views:9

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

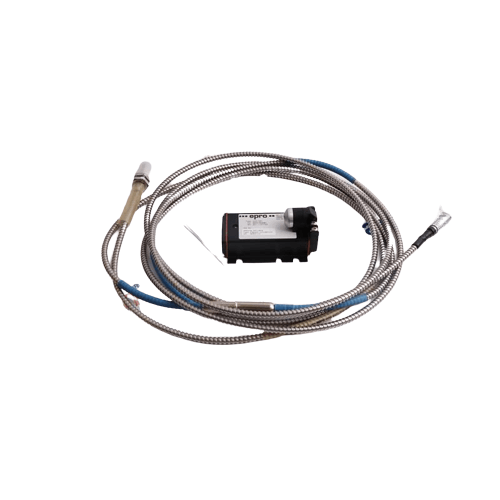

The Emerson VE4050E1C0 KJ4001X1-BE1 DeltaV Input Output Carrier is a critical hardware component within the DeltaV distributed control system (DCS). It serves as the physical platform for mounting and interconnecting I/O modules, ensuring seamless signal routing and reliable communication between field devices and the DeltaV system.

Designed for industrial environments, the carrier supports high-density installations, stable module alignment, and robust connectivity. With its modular structure, it simplifies system expansion, maintenance, and integration with process automation architectures.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | VE4050E1C0 KJ4001X1-BE1 |

| Product Type | DeltaV Input Output Carrier |

| Dimensions | 330 x 140 x 50 mm |

| Weight | 0.689 kg |

| Material | Industrial-grade reinforced polymer |

| Mounting Style | DIN rail or panel mount |

| Supported Modules | DeltaV I/O modules (various types) |

| Connector Type | Multi-pin backplane interface |

| Operating Voltage Range | Compatible with DeltaV I/O modules |

| Environmental Rating | Designed for industrial environments |

| System Compatibility | DeltaV Distributed Control System |

Product Applications

Process Automation Systems – Integrates sensors, transmitters, and actuators into DeltaV controllers.

Power and Utilities – Provides secure signal interfacing for monitoring and control of generation and distribution.

Oil & Gas – Supports complex I/O requirements in upstream, midstream, and downstream automation.

Pharmaceutical Manufacturing – Ensures accurate data acquisition and compliance in batch control systems.

Chemical Processing – Facilitates safe and reliable interconnection of process-critical field devices.

Product Advantages

Modular Scalability – Allows flexible expansion by adding additional carriers and I/O modules.

Robust Connectivity – Ensures strong signal integrity and stable backplane communication.

Ease of Maintenance – Hot-swappable design supports module replacement without system downtime.

Industrial Durability – Built with high-quality materials to withstand harsh operating conditions.

Space Optimization – Compact dimensions enable high-density installation in control cabinets.

Seamless Integration – Natively compatible with DeltaV DCS architecture, reducing setup complexity.

FAQ

Q1: What type of I/O modules can be mounted on the VE4050E1C0 carrier?

A1: It supports a wide range of DeltaV I/O modules including discrete, analog, and specialty I/O.

Q2: How does the carrier communicate with the DeltaV controller?

A2: Communication is achieved through its backplane connectors that link directly to the DeltaV controller.

Q3: Can this carrier support redundant configurations?

A3: Yes, it can be configured with redundant I/O and controllers to improve system reliability.

Q4: Is hot-swapping supported for I/O modules on this carrier?

A4: Yes, modules can be replaced while the system is operational without interrupting other channels.

Q5: How many I/O modules can be mounted on a single carrier?

A5: The number depends on the DeltaV I/O type, but generally multiple modules can be installed per carrier.

Q6: What is the carrier’s role in grounding and shielding?

A6: It provides grounding paths and shielding to minimize electrical noise and signal interference.

Q7: Does the carrier require external power supply?

A7: No, power is distributed via the DeltaV backplane connection integrated into the system.

Q8: Can the carrier be used in hazardous area installations?

A8: Yes, when paired with certified I/O modules, it is suitable for hazardous-rated installations.

Q9: How does the carrier improve system expansion?

A9: Additional carriers can be easily added to the system for scaling up I/O capacity without redesign.

Q10: Is there any firmware associated with the carrier itself?

A10: No, the carrier is a passive hardware component; firmware resides in the I/O modules and controllers.

Emerson VE4050E1C0 KJ4001X1-BE1 DeltaV Input Output Carrier

Manufacturer:Emerson

Product Number: VE4050E1C0 KJ4001X1-BE1

Product Type:DeltaV Input Output Carrier

Origin:USA

Dimensions:330 x 140 x 50 mm

Weight :0.689 kg

Views:9

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Emerson VE4050E1C0 KJ4001X1-BE1 DeltaV Input Output Carrier is a critical hardware component within the DeltaV distributed control system (DCS). It serves as the physical platform for mounting and interconnecting I/O modules, ensuring seamless signal routing and reliable communication between field devices and the DeltaV system.

Designed for industrial environments, the carrier supports high-density installations, stable module alignment, and robust connectivity. With its modular structure, it simplifies system expansion, maintenance, and integration with process automation architectures.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | VE4050E1C0 KJ4001X1-BE1 |

| Product Type | DeltaV Input Output Carrier |

| Dimensions | 330 x 140 x 50 mm |

| Weight | 0.689 kg |

| Material | Industrial-grade reinforced polymer |

| Mounting Style | DIN rail or panel mount |

| Supported Modules | DeltaV I/O modules (various types) |

| Connector Type | Multi-pin backplane interface |

| Operating Voltage Range | Compatible with DeltaV I/O modules |

| Environmental Rating | Designed for industrial environments |

| System Compatibility | DeltaV Distributed Control System |

Product Applications

Process Automation Systems – Integrates sensors, transmitters, and actuators into DeltaV controllers.

Power and Utilities – Provides secure signal interfacing for monitoring and control of generation and distribution.

Oil & Gas – Supports complex I/O requirements in upstream, midstream, and downstream automation.

Pharmaceutical Manufacturing – Ensures accurate data acquisition and compliance in batch control systems.

Chemical Processing – Facilitates safe and reliable interconnection of process-critical field devices.

Product Advantages

Modular Scalability – Allows flexible expansion by adding additional carriers and I/O modules.

Robust Connectivity – Ensures strong signal integrity and stable backplane communication.

Ease of Maintenance – Hot-swappable design supports module replacement without system downtime.

Industrial Durability – Built with high-quality materials to withstand harsh operating conditions.

Space Optimization – Compact dimensions enable high-density installation in control cabinets.

Seamless Integration – Natively compatible with DeltaV DCS architecture, reducing setup complexity.

FAQ

Q1: What type of I/O modules can be mounted on the VE4050E1C0 carrier?

A1: It supports a wide range of DeltaV I/O modules including discrete, analog, and specialty I/O.

Q2: How does the carrier communicate with the DeltaV controller?

A2: Communication is achieved through its backplane connectors that link directly to the DeltaV controller.

Q3: Can this carrier support redundant configurations?

A3: Yes, it can be configured with redundant I/O and controllers to improve system reliability.

Q4: Is hot-swapping supported for I/O modules on this carrier?

A4: Yes, modules can be replaced while the system is operational without interrupting other channels.

Q5: How many I/O modules can be mounted on a single carrier?

A5: The number depends on the DeltaV I/O type, but generally multiple modules can be installed per carrier.

Q6: What is the carrier’s role in grounding and shielding?

A6: It provides grounding paths and shielding to minimize electrical noise and signal interference.

Q7: Does the carrier require external power supply?

A7: No, power is distributed via the DeltaV backplane connection integrated into the system.

Q8: Can the carrier be used in hazardous area installations?

A8: Yes, when paired with certified I/O modules, it is suitable for hazardous-rated installations.

Q9: How does the carrier improve system expansion?

A9: Additional carriers can be easily added to the system for scaling up I/O capacity without redesign.

Q10: Is there any firmware associated with the carrier itself?

A10: No, the carrier is a passive hardware component; firmware resides in the I/O modules and controllers.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...