Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

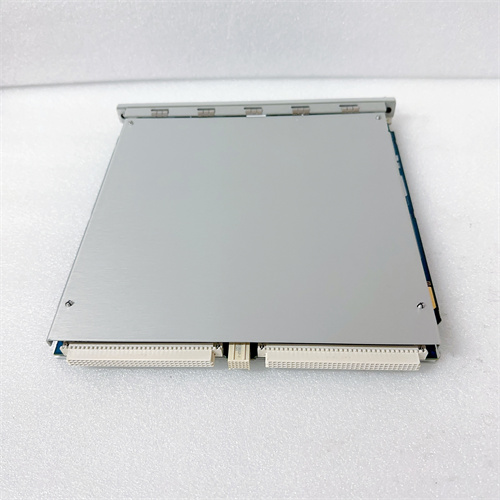

Bently Nevada 3300/55-01-04-12-12-00-00-05-01 Dual Velocity Monitor

Brand:Bently Nevada

Model Number:3300/55-01-04-12-12-00-00-05-01

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:5.7 cm x 20.3 cm x 33.0 cm

Weight:1.5 kg

Price:USD59

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 3300/55 Dual Velocity Monitor is designed for continuous online machinery vibration monitoring. This device features two channels of vibration measurement, allowing you to monitor two different points on a machine simultaneously.

Key Features and Specifications

- Two Channels of Vibration Measurement: Monitor two points on a machine at the same time.

- Accepts Velomitor® Transducers: Utilizes Velomitor® transducers to measure vibration velocity.

- High Sensitivity: Detects even minor changes in vibration levels.

- Wide Frequency Range: Covers a broad spectrum of frequencies, from low to high.

- Rugged Construction: Built to endure harsh industrial environments.

- Easy Installation and Operation: Simplifies setup and usage.

Applications

The Bently Nevada 3300/55 Dual Velocity Monitor finds use in various industrial applications, such as:

- Rotating Machinery: Includes turbines, pumps, fans, compressors, and other rotating equipment.

- Reciprocating Machinery: Applicable to engines, compressors, and other reciprocating equipment.

- Critical Machinery: Ideal for equipment essential to plant or facility operations.

Benefits

Employing the Bently Nevada 3300/55 Dual Velocity Monitor offers several advantages:

- Early Fault Detection: Identifies potential issues before they cause catastrophic failures.

- Reduced Downtime: Minimizes unplanned shutdowns and maintenance costs.

- Improved Safety: Helps prevent accidents and injuries.

- Increased Efficiency: Enhances the performance of machinery.

Bently Nevada 3300/55-01-04-12-12-00-00-05-01 Dual Velocity Monitor

Brand:Bently Nevada

Model Number:3300/55-01-04-12-12-00-00-05-01

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:5.7 cm x 20.3 cm x 33.0 cm

Weight:1.5 kg

Price:USD59

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 3300/55 Dual Velocity Monitor is designed for continuous online machinery vibration monitoring. This device features two channels of vibration measurement, allowing you to monitor two different points on a machine simultaneously.

Key Features and Specifications

- Two Channels of Vibration Measurement: Monitor two points on a machine at the same time.

- Accepts Velomitor® Transducers: Utilizes Velomitor® transducers to measure vibration velocity.

- High Sensitivity: Detects even minor changes in vibration levels.

- Wide Frequency Range: Covers a broad spectrum of frequencies, from low to high.

- Rugged Construction: Built to endure harsh industrial environments.

- Easy Installation and Operation: Simplifies setup and usage.

Applications

The Bently Nevada 3300/55 Dual Velocity Monitor finds use in various industrial applications, such as:

- Rotating Machinery: Includes turbines, pumps, fans, compressors, and other rotating equipment.

- Reciprocating Machinery: Applicable to engines, compressors, and other reciprocating equipment.

- Critical Machinery: Ideal for equipment essential to plant or facility operations.

Benefits

Employing the Bently Nevada 3300/55 Dual Velocity Monitor offers several advantages:

- Early Fault Detection: Identifies potential issues before they cause catastrophic failures.

- Reduced Downtime: Minimizes unplanned shutdowns and maintenance costs.

- Improved Safety: Helps prevent accidents and injuries.

- Increased Efficiency: Enhances the performance of machinery.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...