Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

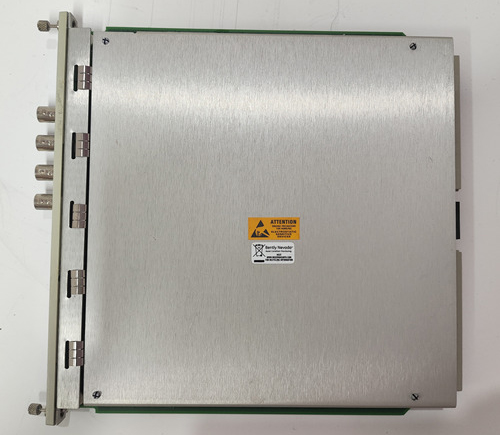

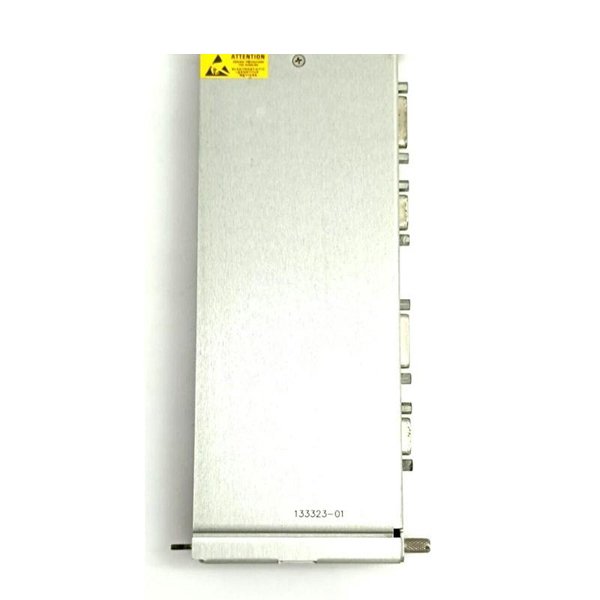

Bently Nevada 3500/92-02-01-00 133323-01 Communication Gateway Module

Manufacturer:Bently Nevada

Product Number:3500/92-02-01-00 133323-01

Product Type:Communication Gateway Module

Origin:USA

Dimensions:241 x 24.4 x 99.1 mm

Weight:0.44kg

Views:59

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/92-02-01-00 133323-01 Communication Gateway Module is an advanced solution designed to facilitate communication between the Bently Nevada 3500 Series machinery protection and condition monitoring systems and external systems such as Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), or supervisory control systems. By providing seamless data transfer capabilities, this module allows operators to remotely monitor, control, and receive diagnostic information from machinery and equipment in real time.

The 3500/92 Communication Gateway supports multiple communication protocols, including Modbus, Ethernet, and industrial network protocols, making it highly versatile and adaptable to different industrial environments. Whether used in power generation, oil and gas, or manufacturing, the module helps to enhance plant efficiency, reduce downtime, and improve safety through real-time data visibility and system integration.

With a compact design, rugged construction, and ease of integration, the 3500/92 ensures that critical machine health data is communicated efficiently, enabling quicker response times to potential issues and better maintenance planning.

Product Parameters

| Parameter | Value |

|---|---|

| Model | 3500/92-02-01-00 |

| Part Number | 133323-01 |

| Dimensions | 241 x 24.4 x 99.1 mm |

| Weight | 0.44 kg |

| Communication Protocols | Modbus, Ethernet, Industrial Network |

| Input/Output Channels | 2 Ethernet Ports, 1 RS-485 Port |

| Power Consumption | < 5 W |

| Mounting | 3500 Series Rack Slot |

| Operating Temperature | –40 °C to +70 °C |

| Humidity | 0–95% non-condensing |

| EMI/RFI Protection | Yes, meets industrial electromagnetic interference (EMI) standards |

| Compliance | CE, UL, IEC 61000 compliant |

| Data Rate | 10/100 Mbps Ethernet, 9600 bps RS-485 |

Product Applications

The 3500/92-02-01-00 Communication Gateway is designed to integrate seamlessly into a wide range of applications across various industries:

Machinery Protection Systems: Enables the integration of machinery condition monitoring systems into central control systems, allowing remote monitoring and data access.

Industrial Automation: Facilitates communication between the 3500 monitoring system and industrial automation devices, supporting predictive maintenance and real-time monitoring.

Oil & Gas Industry: Ensures reliable communication between offshore platforms, refineries, and onshore monitoring stations, improving operational safety.

Power Generation Plants: Supports communication between turbine and generator monitoring systems and DCS for better control and performance tracking.

Manufacturing Plants: Provides remote access to machinery health data, improving decision-making and reducing unplanned downtime.

Chemical and Petrochemical Plants: Facilitates real-time machinery condition monitoring, ensuring safety and reducing the risk of operational disruptions.

Product Advantages

Wide Communication Protocol Support – Supports Modbus, Ethernet, and industrial network protocols, making it adaptable to various system configurations.

Real-Time Data Monitoring – Enables real-time monitoring of machinery health, improving the ability to detect issues before they result in unplanned downtime.

Compact and Space-Efficient – The module is designed to occupy a single rack slot, minimizing space usage while maintaining high functionality.

Easy Integration – Seamlessly integrates into existing DCS and PLC systems, allowing for efficient data transfer and system connectivity.

Durability and Reliability – Built to withstand harsh industrial environments, offering high resistance to EMI and RFI interference.

Low Power Consumption – With a power consumption of less than 5 watts, the module is energy-efficient, reducing operational costs.

Flexible Configuration Options – Offers customizable settings and alarms, allowing users to tailor the system to meet specific application requirements.

Enhanced Monitoring – Provides data on the status of machinery, such as vibration, temperature, and pressure, helping to optimize maintenance schedules.

High Data Transfer Rate – Supports Ethernet data rates of 10/100 Mbps, enabling fast and efficient communication.

Industry Standard Compliance – Complies with CE, UL, and IEC 61000 standards, ensuring it meets the necessary industrial certifications for use in a wide range of environments.

FAQs

Q1: What communication protocols are supported by the 3500/92-02-01-00 module?

A1: The module supports Modbus, Ethernet, and industrial network protocols.

Q2: How many channels does the module provide for communication?

A2: The module provides 2 Ethernet ports and 1 RS-485 port.

Q3: What is the power consumption of the module?

A3: The power consumption is less than 5 watts.

Q4: Can the module be used for remote monitoring?

A4: Yes, the module enables remote monitoring of machinery health and status by connecting to control systems like DCS or PLC.

Q5: What is the temperature range within which the module operates?

A5: The operating temperature range is –40 °C to +70 °C.

Q6: Is the module compatible with different industrial networks?

A6: Yes, the 3500/92-02-01-00 supports multiple communication protocols, including Modbus and Ethernet, for compatibility with various industrial systems.

Q7: How is the module mounted?

A7: The module is mounted in a standard 3500 Series rack slot.

Q8: What is the data transfer speed of the Ethernet ports?

A8: The Ethernet ports support 10/100 Mbps data transfer speeds.

Q9: Is the module suitable for use in hazardous environments?

A9: Yes, it meets EMI/RFI protection standards, making it suitable for industrial and hazardous environments.

Q10: What industries are most likely to benefit from this communication gateway module?

A10: Industries such as power generation, oil & gas, petrochemicals, manufacturing, and industrial automation can all benefit from this module.

Bently Nevada 3500/92-02-01-00 133323-01 Communication Gateway Module

Manufacturer:Bently Nevada

Product Number:3500/92-02-01-00 133323-01

Product Type:Communication Gateway Module

Origin:USA

Dimensions:241 x 24.4 x 99.1 mm

Weight:0.44kg

Views:59

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/92-02-01-00 133323-01 Communication Gateway Module is an advanced solution designed to facilitate communication between the Bently Nevada 3500 Series machinery protection and condition monitoring systems and external systems such as Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), or supervisory control systems. By providing seamless data transfer capabilities, this module allows operators to remotely monitor, control, and receive diagnostic information from machinery and equipment in real time.

The 3500/92 Communication Gateway supports multiple communication protocols, including Modbus, Ethernet, and industrial network protocols, making it highly versatile and adaptable to different industrial environments. Whether used in power generation, oil and gas, or manufacturing, the module helps to enhance plant efficiency, reduce downtime, and improve safety through real-time data visibility and system integration.

With a compact design, rugged construction, and ease of integration, the 3500/92 ensures that critical machine health data is communicated efficiently, enabling quicker response times to potential issues and better maintenance planning.

Product Parameters

| Parameter | Value |

|---|---|

| Model | 3500/92-02-01-00 |

| Part Number | 133323-01 |

| Dimensions | 241 x 24.4 x 99.1 mm |

| Weight | 0.44 kg |

| Communication Protocols | Modbus, Ethernet, Industrial Network |

| Input/Output Channels | 2 Ethernet Ports, 1 RS-485 Port |

| Power Consumption | < 5 W |

| Mounting | 3500 Series Rack Slot |

| Operating Temperature | –40 °C to +70 °C |

| Humidity | 0–95% non-condensing |

| EMI/RFI Protection | Yes, meets industrial electromagnetic interference (EMI) standards |

| Compliance | CE, UL, IEC 61000 compliant |

| Data Rate | 10/100 Mbps Ethernet, 9600 bps RS-485 |

Product Applications

The 3500/92-02-01-00 Communication Gateway is designed to integrate seamlessly into a wide range of applications across various industries:

Machinery Protection Systems: Enables the integration of machinery condition monitoring systems into central control systems, allowing remote monitoring and data access.

Industrial Automation: Facilitates communication between the 3500 monitoring system and industrial automation devices, supporting predictive maintenance and real-time monitoring.

Oil & Gas Industry: Ensures reliable communication between offshore platforms, refineries, and onshore monitoring stations, improving operational safety.

Power Generation Plants: Supports communication between turbine and generator monitoring systems and DCS for better control and performance tracking.

Manufacturing Plants: Provides remote access to machinery health data, improving decision-making and reducing unplanned downtime.

Chemical and Petrochemical Plants: Facilitates real-time machinery condition monitoring, ensuring safety and reducing the risk of operational disruptions.

Product Advantages

Wide Communication Protocol Support – Supports Modbus, Ethernet, and industrial network protocols, making it adaptable to various system configurations.

Real-Time Data Monitoring – Enables real-time monitoring of machinery health, improving the ability to detect issues before they result in unplanned downtime.

Compact and Space-Efficient – The module is designed to occupy a single rack slot, minimizing space usage while maintaining high functionality.

Easy Integration – Seamlessly integrates into existing DCS and PLC systems, allowing for efficient data transfer and system connectivity.

Durability and Reliability – Built to withstand harsh industrial environments, offering high resistance to EMI and RFI interference.

Low Power Consumption – With a power consumption of less than 5 watts, the module is energy-efficient, reducing operational costs.

Flexible Configuration Options – Offers customizable settings and alarms, allowing users to tailor the system to meet specific application requirements.

Enhanced Monitoring – Provides data on the status of machinery, such as vibration, temperature, and pressure, helping to optimize maintenance schedules.

High Data Transfer Rate – Supports Ethernet data rates of 10/100 Mbps, enabling fast and efficient communication.

Industry Standard Compliance – Complies with CE, UL, and IEC 61000 standards, ensuring it meets the necessary industrial certifications for use in a wide range of environments.

FAQs

Q1: What communication protocols are supported by the 3500/92-02-01-00 module?

A1: The module supports Modbus, Ethernet, and industrial network protocols.

Q2: How many channels does the module provide for communication?

A2: The module provides 2 Ethernet ports and 1 RS-485 port.

Q3: What is the power consumption of the module?

A3: The power consumption is less than 5 watts.

Q4: Can the module be used for remote monitoring?

A4: Yes, the module enables remote monitoring of machinery health and status by connecting to control systems like DCS or PLC.

Q5: What is the temperature range within which the module operates?

A5: The operating temperature range is –40 °C to +70 °C.

Q6: Is the module compatible with different industrial networks?

A6: Yes, the 3500/92-02-01-00 supports multiple communication protocols, including Modbus and Ethernet, for compatibility with various industrial systems.

Q7: How is the module mounted?

A7: The module is mounted in a standard 3500 Series rack slot.

Q8: What is the data transfer speed of the Ethernet ports?

A8: The Ethernet ports support 10/100 Mbps data transfer speeds.

Q9: Is the module suitable for use in hazardous environments?

A9: Yes, it meets EMI/RFI protection standards, making it suitable for industrial and hazardous environments.

Q10: What industries are most likely to benefit from this communication gateway module?

A10: Industries such as power generation, oil & gas, petrochemicals, manufacturing, and industrial automation can all benefit from this module.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...