Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

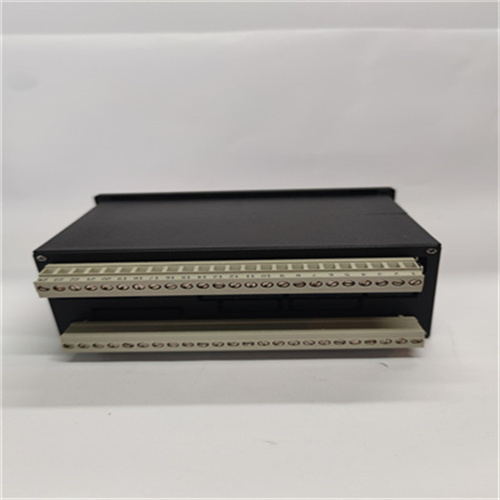

Woodward 8237-1600 Overspeed Safety Device

Manufacturer:Woodward

Product Number:8237-1600

Product Type:Overspeed Safety Device

Origin:USA

Dimensions:196 x 143 x 86 mm

Weight:12 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 8237-1600 Overspeed Safety Device is an advanced, independent protection system engineered to monitor and instantly respond to overspeed conditions in rotating machinery such as turbines, compressors, and generators. As a trusted solution in high-reliability environments, this device plays a critical role in ensuring the operational safety and mechanical integrity of high-speed rotating systems.

The 8237-1600 is specifically designed to perform fail-safe tripping when the rotational speed exceeds configured safety thresholds. Utilizing fast-response digital processing and redundant trip paths, the unit is built to comply with stringent industry standards like API 612, API 670, and IEC safety regulations.

Engineered and manufactured by Woodward, a global leader in industrial control solutions, this device embodies decades of innovation in turbine protection and safety systems.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 8237-1600 |

| Product Type | Overspeed Safety Device (OSD) |

| Application | Overspeed protection for turbines, compressors, etc. |

| Speed Range | Up to 25,000 RPM (configurable per application) |

| Trip Setpoint Accuracy | ±0.25% of full scale |

| Response Time | < 5 milliseconds |

| Number of Speed Inputs | 3 Magnetic or Proximity Pickup Inputs (redundant) |

| Trip Relays | 2 or more, redundant, Form C, 5 A @ 30 VDC |

| Self-Test Functionality | Yes, automatic and manual initiation |

| Safety Certifications | SIL-3 capable, API 670 compliant |

| Mounting | Panel-mounted (DIN rail optional with adapter) |

| Operating Temperature | -20°C to +70°C |

| Humidity Range | 5%–95% RH, non-condensing |

| Power Supply | 18–32 VDC |

| Interface | LCD display with keypad / RS-232 or Modbus RTU |

| Event Logging | Built-in non-volatile memory (100+ events) |

| Dimensions (H x W x D) | 196 x 143 x 86 mm |

| Weight | 12 kg |

| Enclosure Rating | IP20 (for panel-mount applications) |

| Compliance Standards | CE, UL, CSA, API 612/670, IEC 61508 SIL-3 |

Product Applications

The Woodward 8237-1600 is ideal for mission-critical applications where overspeed poses catastrophic risks. It is commonly deployed in:

Steam Turbines: In power generation plants, to prevent turbine failure due to shaft overspeed.

Gas Turbines: As a final line of defense in turbine protection systems.

Centrifugal Compressors: For dynamic process control and system shutdown in fault scenarios.

Industrial Generators: To protect from frequency drift or electrical failure-induced overspeed.

Marine Propulsion Systems: To ensure safety in marine engines operating under variable loads.

Mechanical Test Benches: In R&D facilities, to enforce rotational safety standards.

Product Advantages

Independent Safety Logic: Operates autonomously from the main control system to ensure fail-safe operation even in controller failure scenarios.

Ultra-Fast Response: Provides a <5 ms trip reaction time—essential for high-speed rotating equipment.

Triple-Redundant Speed Inputs: Enhances reliability by continuously validating input signal integrity from three sensors.

Built-In Self-Test and Diagnostics: Routine self-checks and fault logging support predictive maintenance.

Compact and Rugged Design: Compact form factor with high resistance to vibration, temperature, and electrical noise.

SIL-3 Capable: Designed in compliance with Safety Integrity Level 3 requirements, suitable for critical applications.

Flexible Interface Options: Includes local LCD display, keypad, and serial communication for easy configuration and monitoring.

Industry Compliant: Meets major safety and performance standards including API 670 and IEC 61508.

Frequently Asked Questions (FAQ)

What is the primary function of the 8237-1600 device?

It monitors rotational speed and initiates a trip when the configured overspeed threshold is exceeded.

Is the 8237-1600 certified for safety-critical applications?

Yes, it is SIL-3 capable and compliant with API 670 and IEC 61508 standards.

What types of sensors are compatible with this device?

It supports magnetic pickups and proximity probes with TTL/AC inputs.

Can it be integrated with a DCS or PLC system?

Yes, it supports Modbus RTU and RS-232 serial communication for integration.

Does the device log events?

Yes, it includes a non-volatile memory to store over 100 event records.

How accurate is the trip setpoint?

The trip setpoint has a typical accuracy of ±0.25% of full scale.

Is this product suitable for marine environments?

Yes, as long as it is mounted in a protected enclosure meeting IP standards.

How is the overspeed threshold configured?

Configuration is done via onboard keypad/LCD or through a connected PC.

What is the power supply requirement?

It operates on 18–32 VDC, typical of industrial control power supplies.

Can the unit perform self-diagnostics?

Yes, both automatic and manual self-tests are available to verify system integrity.

Woodward 8237-1600 Overspeed Safety Device

Manufacturer:Woodward

Product Number:8237-1600

Product Type:Overspeed Safety Device

Origin:USA

Dimensions:196 x 143 x 86 mm

Weight:12 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 8237-1600 Overspeed Safety Device is an advanced, independent protection system engineered to monitor and instantly respond to overspeed conditions in rotating machinery such as turbines, compressors, and generators. As a trusted solution in high-reliability environments, this device plays a critical role in ensuring the operational safety and mechanical integrity of high-speed rotating systems.

The 8237-1600 is specifically designed to perform fail-safe tripping when the rotational speed exceeds configured safety thresholds. Utilizing fast-response digital processing and redundant trip paths, the unit is built to comply with stringent industry standards like API 612, API 670, and IEC safety regulations.

Engineered and manufactured by Woodward, a global leader in industrial control solutions, this device embodies decades of innovation in turbine protection and safety systems.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 8237-1600 |

| Product Type | Overspeed Safety Device (OSD) |

| Application | Overspeed protection for turbines, compressors, etc. |

| Speed Range | Up to 25,000 RPM (configurable per application) |

| Trip Setpoint Accuracy | ±0.25% of full scale |

| Response Time | < 5 milliseconds |

| Number of Speed Inputs | 3 Magnetic or Proximity Pickup Inputs (redundant) |

| Trip Relays | 2 or more, redundant, Form C, 5 A @ 30 VDC |

| Self-Test Functionality | Yes, automatic and manual initiation |

| Safety Certifications | SIL-3 capable, API 670 compliant |

| Mounting | Panel-mounted (DIN rail optional with adapter) |

| Operating Temperature | -20°C to +70°C |

| Humidity Range | 5%–95% RH, non-condensing |

| Power Supply | 18–32 VDC |

| Interface | LCD display with keypad / RS-232 or Modbus RTU |

| Event Logging | Built-in non-volatile memory (100+ events) |

| Dimensions (H x W x D) | 196 x 143 x 86 mm |

| Weight | 12 kg |

| Enclosure Rating | IP20 (for panel-mount applications) |

| Compliance Standards | CE, UL, CSA, API 612/670, IEC 61508 SIL-3 |

Product Applications

The Woodward 8237-1600 is ideal for mission-critical applications where overspeed poses catastrophic risks. It is commonly deployed in:

Steam Turbines: In power generation plants, to prevent turbine failure due to shaft overspeed.

Gas Turbines: As a final line of defense in turbine protection systems.

Centrifugal Compressors: For dynamic process control and system shutdown in fault scenarios.

Industrial Generators: To protect from frequency drift or electrical failure-induced overspeed.

Marine Propulsion Systems: To ensure safety in marine engines operating under variable loads.

Mechanical Test Benches: In R&D facilities, to enforce rotational safety standards.

Product Advantages

Independent Safety Logic: Operates autonomously from the main control system to ensure fail-safe operation even in controller failure scenarios.

Ultra-Fast Response: Provides a <5 ms trip reaction time—essential for high-speed rotating equipment.

Triple-Redundant Speed Inputs: Enhances reliability by continuously validating input signal integrity from three sensors.

Built-In Self-Test and Diagnostics: Routine self-checks and fault logging support predictive maintenance.

Compact and Rugged Design: Compact form factor with high resistance to vibration, temperature, and electrical noise.

SIL-3 Capable: Designed in compliance with Safety Integrity Level 3 requirements, suitable for critical applications.

Flexible Interface Options: Includes local LCD display, keypad, and serial communication for easy configuration and monitoring.

Industry Compliant: Meets major safety and performance standards including API 670 and IEC 61508.

Frequently Asked Questions (FAQ)

What is the primary function of the 8237-1600 device?

It monitors rotational speed and initiates a trip when the configured overspeed threshold is exceeded.

Is the 8237-1600 certified for safety-critical applications?

Yes, it is SIL-3 capable and compliant with API 670 and IEC 61508 standards.

What types of sensors are compatible with this device?

It supports magnetic pickups and proximity probes with TTL/AC inputs.

Can it be integrated with a DCS or PLC system?

Yes, it supports Modbus RTU and RS-232 serial communication for integration.

Does the device log events?

Yes, it includes a non-volatile memory to store over 100 event records.

How accurate is the trip setpoint?

The trip setpoint has a typical accuracy of ±0.25% of full scale.

Is this product suitable for marine environments?

Yes, as long as it is mounted in a protected enclosure meeting IP standards.

How is the overspeed threshold configured?

Configuration is done via onboard keypad/LCD or through a connected PC.

What is the power supply requirement?

It operates on 18–32 VDC, typical of industrial control power supplies.

Can the unit perform self-diagnostics?

Yes, both automatic and manual self-tests are available to verify system integrity.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...