Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

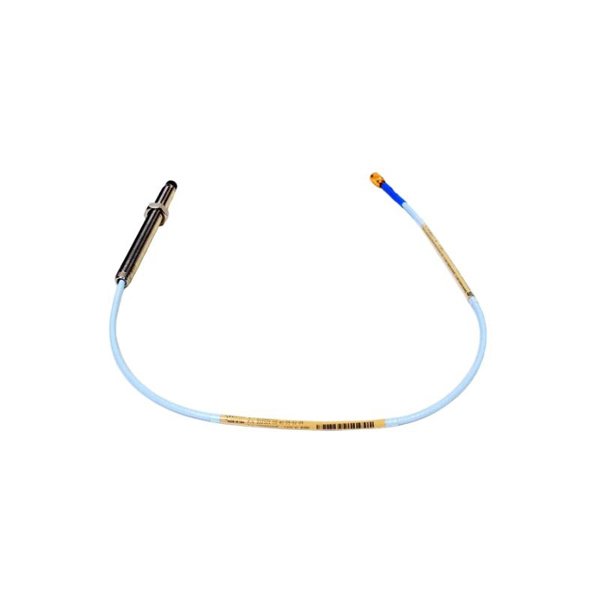

Bently Nevada 330103-00-02-05-02-00 3300 XL 8mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-00-02-05-02-00

Product Type:3300 XL 8mm Proximity Probe (Metric)

Origin:USA

Total Length:0.5 meter

Weight:0.162kg

Views:44

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-02-05-02-00 3300 XL 8mm Proximity Probe (Metric) is a precision sensor designed for non-contact measurement of vibration, displacement, and position in rotating machinery. It is part of the 3300 XL series, offering a robust and reliable solution for monitoring machinery health in a variety of industrial applications. The probe utilizes eddy current technology, which allows for accurate measurements without physical contact with the target, thus minimizing wear and tear over time.

This proximity probe is designed specifically for metric applications with an 8mm diameter, making it compatible with global industrial standards. It is ideal for use in challenging industrial environments where reliability, accuracy, and durability are paramount.

With its compact size and durable construction, the 3300 XL 8mm Proximity Probe is widely used in industries such as power generation, manufacturing, oil and gas, and process control, helping to prevent failures, reduce downtime, and optimize machinery performance through condition-based monitoring.

Key Features

High-Precision Measurement: The 3300 XL proximity probe provides accurate vibration and displacement measurements, which are essential for monitoring the health of rotating machinery and identifying potential faults early.

Non-Contact Technology: Utilizing eddy current technology, the probe operates without direct contact with the machinery, minimizing wear and extending the lifespan of both the probe and the equipment being monitored.

Compact and Lightweight: The probe is lightweight and has a compact 8mm diameter, making it ideal for space-constrained installations while providing high accuracy.

Durable and Reliable: Built to withstand harsh environments, the 3300 XL probe is highly resistant to vibrations, extreme temperatures, and chemical exposure, ensuring reliable performance in industrial settings.

Metric Size: Specifically designed for metric applications, the 8mm diameter ensures compatibility with international measurement standards, making it suitable for global operations.

Easy Integration: Designed to seamlessly integrate with other Bently Nevada systems, the 3300 XL probe can be easily incorporated into existing machinery monitoring systems.

Product Parameters

| Parameter | Value |

|---|---|

| Total Length | 0.5 meter |

| Weight | 0.162 kg |

| Proximity Probe Diameter | 8 mm |

| Operating Temperature | -40°C to 120°C |

| Cable Length | 0.5 meter |

| Signal Type | Eddy Current |

| Sensitivity | High Sensitivity |

| Mounting Type | Non-contact |

Product Applications

The Bently Nevada 330103-00-02-05-02-00 3300 XL 8mm Proximity Probe (Metric) is designed for use in a wide range of industrial applications where the health of rotating machinery needs to be continuously monitored. Some key applications include:

Rotating Machinery Monitoring: Widely used in industries where rotating equipment such as motors, turbines, compressors, and pumps are critical, the 3300 XL probe helps monitor their performance and detect early signs of wear, misalignment, or unbalance.

Condition-Based Monitoring Systems: Integrated into condition monitoring systems, this probe provides real-time measurements of vibration and displacement, which are essential for predictive maintenance programs aimed at preventing failures before they occur.

Predictive Maintenance: By continuously measuring displacement and vibration, the 3300 XL probe enables predictive maintenance, allowing operators to plan interventions before costly breakdowns happen, thus minimizing unplanned downtime.

Power Generation: In power plants, the probe is used to monitor turbines, generators, and other critical rotating machinery, ensuring continuous monitoring of their health and improving plant reliability.

Oil & Gas Industry: In the oil and gas sector, the 3300 XL probe helps monitor equipment operating in challenging environments, where conditions like extreme temperatures, vibrations, and chemical exposure can lead to machinery failure if not properly managed.

Manufacturing: Used in manufacturing plants, the probe ensures that machinery such as mills, presses, and conveyor systems operate within optimal performance parameters, reducing downtime and maintenance costs.

Advantages of the Product

Highly Accurate Measurements: The 3300 XL proximity probe provides precise displacement and vibration measurements, crucial for identifying early-stage mechanical faults and preventing system failures.

Longer Probe Life: The non-contact nature of the probe, using eddy current technology, ensures that there is no physical wear between the probe and the target, increasing the probe’s lifespan and reducing maintenance needs.

Wide Temperature Range: With an operating temperature range from -40°C to 120°C, the 3300 XL probe is designed to perform reliably even in extreme conditions, making it suitable for use in harsh industrial environments.

Compact Size: The 8mm diameter of the probe makes it suitable for applications with space constraints, allowing for easy installation in confined areas without compromising performance.

Robust Design: Resistant to vibrations, high temperatures, and chemicals, the probe is built to endure the tough operating conditions found in industries like oil and gas, power generation, and heavy manufacturing.

Global Compatibility: The metric size of the 3300 XL probe ensures compatibility with international industrial standards, making it ideal for multinational operations.

Seamless Integration: The probe can be easily integrated with other Bently Nevada monitoring systems, offering a comprehensive and cohesive solution for machinery condition monitoring.

Frequently Asked Questions (FAQ)

What is the primary function of the Bently Nevada 3300 XL 8mm Proximity Probe?

-

The primary function is to measure vibration and displacement in rotating machinery, providing essential data for predictive maintenance and condition-based monitoring.

-

What technology is used in the Bently Nevada 3300 XL probe?

-

The probe uses eddy current technology, which enables non-contact measurement of vibration and displacement.

-

What is the length of the Bently Nevada 3300 XL proximity probe?

-

The total length of the probe is 0.5 meters, making it suitable for a wide range of applications.

-

Can the 3300 XL 8mm Proximity Probe be used in outdoor environments?

-

Yes, the probe can be used in harsh industrial environments, but it should be protected from direct exposure to the elements.

-

What is the operating temperature range of the Bently Nevada 3300 XL probe?

-

The probe operates within a temperature range of -40°C to 120°C, making it suitable for extreme conditions.

-

How does the non-contact measurement feature benefit the Bently Nevada 3300 XL probe?

-

The non-contact nature of the probe reduces wear on both the probe and the monitored equipment, leading to increased longevity and reliable performance over time.

-

What is the diameter of the Bently Nevada 3300 XL 8mm Proximity Probe?

-

The probe has a diameter of 8mm, which is suitable for metric applications and compatible with standard industrial setups.

-

Is the Bently Nevada 3300 XL probe easy to install?

-

Yes, the compact design and standard mounting options make it easy to install, even in tight or space-constrained locations.

-

What industries use the Bently Nevada 3300 XL 8mm Proximity Probe?

-

The probe is used in power generation, oil and gas, manufacturing, and other industries requiring precise vibration and displacement measurements in rotating machinery.

-

Is the Bently Nevada 3300 XL probe compatible with other Bently Nevada products?

-

Yes, the probe integrates seamlessly with other Bently Nevada machinery monitoring systems, providing a comprehensive condition monitoring solution.

-

Bently Nevada 330103-00-02-05-02-00 3300 XL 8mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-00-02-05-02-00

Product Type:3300 XL 8mm Proximity Probe (Metric)

Origin:USA

Total Length:0.5 meter

Weight:0.162kg

Views:44

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-02-05-02-00 3300 XL 8mm Proximity Probe (Metric) is a precision sensor designed for non-contact measurement of vibration, displacement, and position in rotating machinery. It is part of the 3300 XL series, offering a robust and reliable solution for monitoring machinery health in a variety of industrial applications. The probe utilizes eddy current technology, which allows for accurate measurements without physical contact with the target, thus minimizing wear and tear over time.

This proximity probe is designed specifically for metric applications with an 8mm diameter, making it compatible with global industrial standards. It is ideal for use in challenging industrial environments where reliability, accuracy, and durability are paramount.

With its compact size and durable construction, the 3300 XL 8mm Proximity Probe is widely used in industries such as power generation, manufacturing, oil and gas, and process control, helping to prevent failures, reduce downtime, and optimize machinery performance through condition-based monitoring.

Key Features

High-Precision Measurement: The 3300 XL proximity probe provides accurate vibration and displacement measurements, which are essential for monitoring the health of rotating machinery and identifying potential faults early.

Non-Contact Technology: Utilizing eddy current technology, the probe operates without direct contact with the machinery, minimizing wear and extending the lifespan of both the probe and the equipment being monitored.

Compact and Lightweight: The probe is lightweight and has a compact 8mm diameter, making it ideal for space-constrained installations while providing high accuracy.

Durable and Reliable: Built to withstand harsh environments, the 3300 XL probe is highly resistant to vibrations, extreme temperatures, and chemical exposure, ensuring reliable performance in industrial settings.

Metric Size: Specifically designed for metric applications, the 8mm diameter ensures compatibility with international measurement standards, making it suitable for global operations.

Easy Integration: Designed to seamlessly integrate with other Bently Nevada systems, the 3300 XL probe can be easily incorporated into existing machinery monitoring systems.

Product Parameters

| Parameter | Value |

|---|---|

| Total Length | 0.5 meter |

| Weight | 0.162 kg |

| Proximity Probe Diameter | 8 mm |

| Operating Temperature | -40°C to 120°C |

| Cable Length | 0.5 meter |

| Signal Type | Eddy Current |

| Sensitivity | High Sensitivity |

| Mounting Type | Non-contact |

Product Applications

The Bently Nevada 330103-00-02-05-02-00 3300 XL 8mm Proximity Probe (Metric) is designed for use in a wide range of industrial applications where the health of rotating machinery needs to be continuously monitored. Some key applications include:

Rotating Machinery Monitoring: Widely used in industries where rotating equipment such as motors, turbines, compressors, and pumps are critical, the 3300 XL probe helps monitor their performance and detect early signs of wear, misalignment, or unbalance.

Condition-Based Monitoring Systems: Integrated into condition monitoring systems, this probe provides real-time measurements of vibration and displacement, which are essential for predictive maintenance programs aimed at preventing failures before they occur.

Predictive Maintenance: By continuously measuring displacement and vibration, the 3300 XL probe enables predictive maintenance, allowing operators to plan interventions before costly breakdowns happen, thus minimizing unplanned downtime.

Power Generation: In power plants, the probe is used to monitor turbines, generators, and other critical rotating machinery, ensuring continuous monitoring of their health and improving plant reliability.

Oil & Gas Industry: In the oil and gas sector, the 3300 XL probe helps monitor equipment operating in challenging environments, where conditions like extreme temperatures, vibrations, and chemical exposure can lead to machinery failure if not properly managed.

Manufacturing: Used in manufacturing plants, the probe ensures that machinery such as mills, presses, and conveyor systems operate within optimal performance parameters, reducing downtime and maintenance costs.

Advantages of the Product

Highly Accurate Measurements: The 3300 XL proximity probe provides precise displacement and vibration measurements, crucial for identifying early-stage mechanical faults and preventing system failures.

Longer Probe Life: The non-contact nature of the probe, using eddy current technology, ensures that there is no physical wear between the probe and the target, increasing the probe’s lifespan and reducing maintenance needs.

Wide Temperature Range: With an operating temperature range from -40°C to 120°C, the 3300 XL probe is designed to perform reliably even in extreme conditions, making it suitable for use in harsh industrial environments.

Compact Size: The 8mm diameter of the probe makes it suitable for applications with space constraints, allowing for easy installation in confined areas without compromising performance.

Robust Design: Resistant to vibrations, high temperatures, and chemicals, the probe is built to endure the tough operating conditions found in industries like oil and gas, power generation, and heavy manufacturing.

Global Compatibility: The metric size of the 3300 XL probe ensures compatibility with international industrial standards, making it ideal for multinational operations.

Seamless Integration: The probe can be easily integrated with other Bently Nevada monitoring systems, offering a comprehensive and cohesive solution for machinery condition monitoring.

Frequently Asked Questions (FAQ)

What is the primary function of the Bently Nevada 3300 XL 8mm Proximity Probe?

-

The primary function is to measure vibration and displacement in rotating machinery, providing essential data for predictive maintenance and condition-based monitoring.

-

What technology is used in the Bently Nevada 3300 XL probe?

-

The probe uses eddy current technology, which enables non-contact measurement of vibration and displacement.

-

What is the length of the Bently Nevada 3300 XL proximity probe?

-

The total length of the probe is 0.5 meters, making it suitable for a wide range of applications.

-

Can the 3300 XL 8mm Proximity Probe be used in outdoor environments?

-

Yes, the probe can be used in harsh industrial environments, but it should be protected from direct exposure to the elements.

-

What is the operating temperature range of the Bently Nevada 3300 XL probe?

-

The probe operates within a temperature range of -40°C to 120°C, making it suitable for extreme conditions.

-

How does the non-contact measurement feature benefit the Bently Nevada 3300 XL probe?

-

The non-contact nature of the probe reduces wear on both the probe and the monitored equipment, leading to increased longevity and reliable performance over time.

-

What is the diameter of the Bently Nevada 3300 XL 8mm Proximity Probe?

-

The probe has a diameter of 8mm, which is suitable for metric applications and compatible with standard industrial setups.

-

Is the Bently Nevada 3300 XL probe easy to install?

-

Yes, the compact design and standard mounting options make it easy to install, even in tight or space-constrained locations.

-

What industries use the Bently Nevada 3300 XL 8mm Proximity Probe?

-

The probe is used in power generation, oil and gas, manufacturing, and other industries requiring precise vibration and displacement measurements in rotating machinery.

-

Is the Bently Nevada 3300 XL probe compatible with other Bently Nevada products?

-

Yes, the probe integrates seamlessly with other Bently Nevada machinery monitoring systems, providing a comprehensive condition monitoring solution.

-

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...