Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

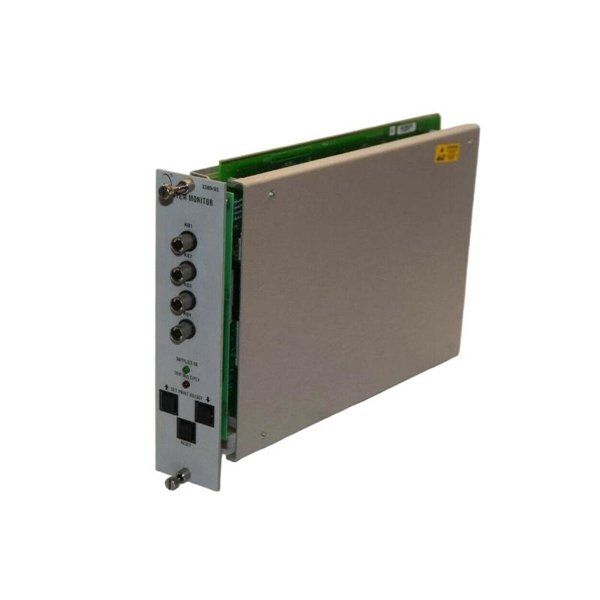

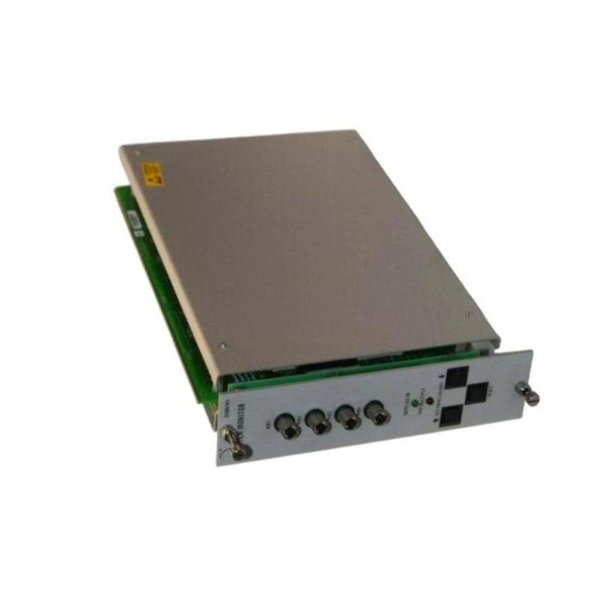

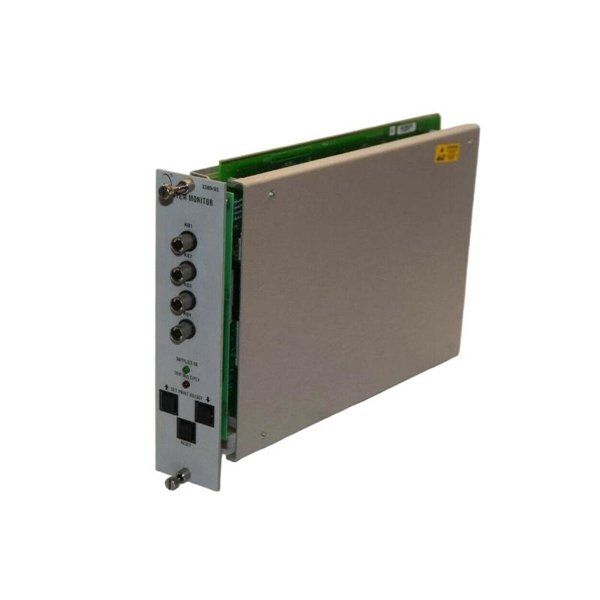

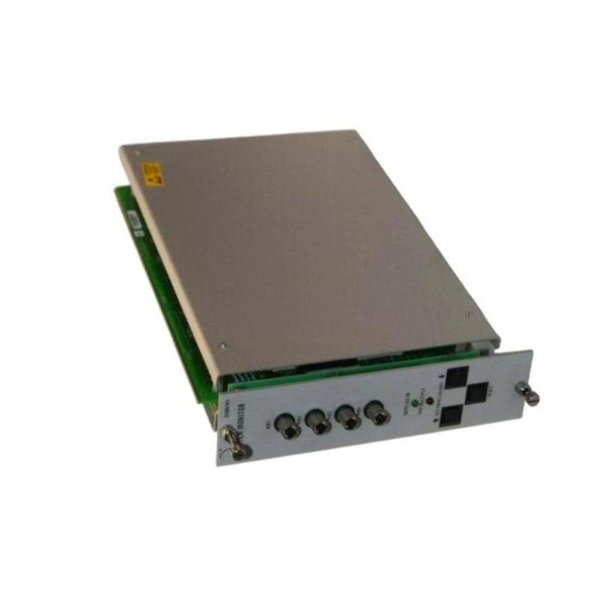

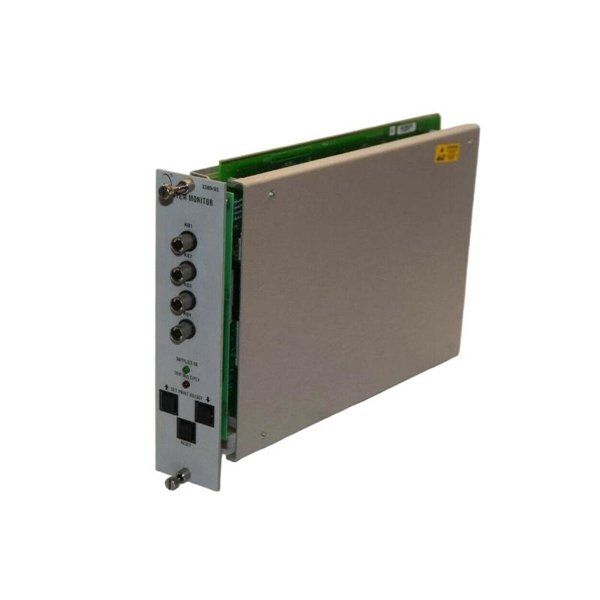

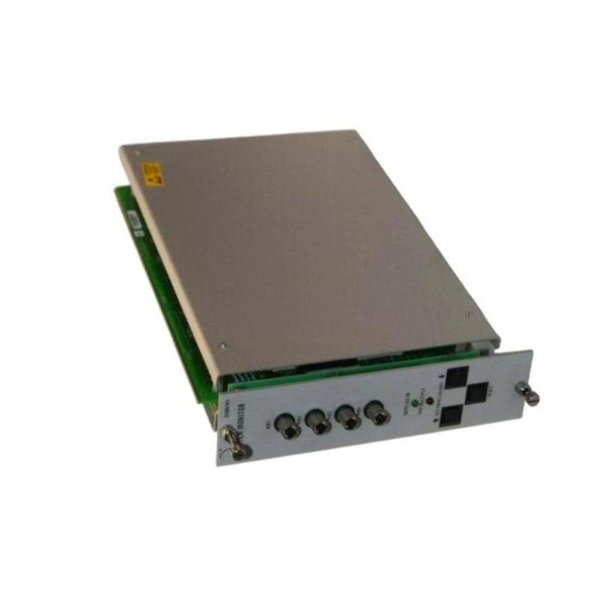

Bently Nevada 3300/03-01-00 System Monitor

Manufacturer:Bently Nevada

Product Number:3300/03-01-00

Product Type:System Monitor

Origin:USA

Dimensions:58.42 × 203.2 × 330.2mm

Weight:0.9kg

Views:99

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300/03-01-00 System Monitor is a core component of the widely recognized 3300 Machinery Protection System, designed to provide real-time monitoring and protection of critical rotating machinery. This system monitor interfaces with proximity probes, vibration sensors, and other field devices to deliver accurate and timely fault detection, ensuring reliable operation and extended equipment life.

Engineered with robust industrial-grade components, the 3300/03-01-00 monitor offers high reliability and ease of integration into complex plant control systems, making it suitable for power generation, oil & gas, petrochemical, and other heavy industries.

Key Features

-

Real-time monitoring and protection for rotating machinery

-

Interfaces seamlessly with Bently Nevada 3300 series probes and sensors

-

Provides multiple alarm and trip set points for machinery protection

-

Modular design for easy maintenance and system expansion

-

Rugged construction suitable for harsh industrial environments

-

Compatible with plant control and condition monitoring systems

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3300/03-01-00 |

| System Type | 3300 Machinery Protection System |

| Input Channels | Up to 8 proximity or vibration sensor inputs |

| Output Types | Relay alarm/trip outputs, 4-20 mA analog outputs |

| Power Supply | 120/240 VAC, 50/60 Hz |

| Operating Temperature | -20°C to +70°C |

| Dimensions | 58.42 × 203.2 × 330.2mm |

| Weight | 0.9 kg |

| Communication Interfaces | Optional serial or Ethernet interfaces available |

| Mounting | Standard 19-inch rack mount |

Industry Applications

-

Machinery protection in power plants, petrochemical, and oil & gas industries

-

Turbines, compressors, pumps, and generators condition monitoring

-

Early fault detection to prevent catastrophic equipment failures

-

Integration into Distributed Control Systems (DCS) and SCADA

-

Rotating equipment health monitoring and maintenance planning

Product Advantages

-

Proven reliability in demanding industrial environments

-

Comprehensive monitoring of multiple machinery parameters

-

Flexible alarm and trip configurations enhance equipment safety

-

Modular and scalable design simplifies system upgrades

-

Supports integration with existing plant control infrastructure

-

Reduces unplanned downtime and maintenance costs

Frequently Asked Questions (FAQ)

What types of sensors are compatible with the 3300/03-01-00 System Monitor?

Compatible with Bently Nevada 3300 series proximity probes and vibration sensors.

How many input channels does the system support?

Up to 8 sensor inputs.

What are the power supply requirements?

120/240 VAC, 50/60 Hz.

What are the system monitor’s dimensions?

Approximately 58.42mm × 203.2mm × 330.2mm.

Can the system outputs interface with plant control systems?

Yes, it provides relay and analog 4-20 mA outputs.

Is the system suitable for harsh industrial environments?

Yes, it is built for rugged industrial use.

Does the monitor support communication interfaces?

Optional serial or Ethernet interfaces are available.

What mounting options does the system have?

Standard 19-inch rack mount.

Can the alarm and trip points be configured?

Yes, they can be customized for specific machinery protection needs.

What industries typically use this system monitor?

Power generation, oil & gas, petrochemical, manufacturing, and heavy industries.

Bently Nevada 3300/03-01-00 System Monitor

Manufacturer:Bently Nevada

Product Number:3300/03-01-00

Product Type:System Monitor

Origin:USA

Dimensions:58.42 × 203.2 × 330.2mm

Weight:0.9kg

Views:99

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300/03-01-00 System Monitor is a core component of the widely recognized 3300 Machinery Protection System, designed to provide real-time monitoring and protection of critical rotating machinery. This system monitor interfaces with proximity probes, vibration sensors, and other field devices to deliver accurate and timely fault detection, ensuring reliable operation and extended equipment life.

Engineered with robust industrial-grade components, the 3300/03-01-00 monitor offers high reliability and ease of integration into complex plant control systems, making it suitable for power generation, oil & gas, petrochemical, and other heavy industries.

Key Features

-

Real-time monitoring and protection for rotating machinery

-

Interfaces seamlessly with Bently Nevada 3300 series probes and sensors

-

Provides multiple alarm and trip set points for machinery protection

-

Modular design for easy maintenance and system expansion

-

Rugged construction suitable for harsh industrial environments

-

Compatible with plant control and condition monitoring systems

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3300/03-01-00 |

| System Type | 3300 Machinery Protection System |

| Input Channels | Up to 8 proximity or vibration sensor inputs |

| Output Types | Relay alarm/trip outputs, 4-20 mA analog outputs |

| Power Supply | 120/240 VAC, 50/60 Hz |

| Operating Temperature | -20°C to +70°C |

| Dimensions | 58.42 × 203.2 × 330.2mm |

| Weight | 0.9 kg |

| Communication Interfaces | Optional serial or Ethernet interfaces available |

| Mounting | Standard 19-inch rack mount |

Industry Applications

-

Machinery protection in power plants, petrochemical, and oil & gas industries

-

Turbines, compressors, pumps, and generators condition monitoring

-

Early fault detection to prevent catastrophic equipment failures

-

Integration into Distributed Control Systems (DCS) and SCADA

-

Rotating equipment health monitoring and maintenance planning

Product Advantages

-

Proven reliability in demanding industrial environments

-

Comprehensive monitoring of multiple machinery parameters

-

Flexible alarm and trip configurations enhance equipment safety

-

Modular and scalable design simplifies system upgrades

-

Supports integration with existing plant control infrastructure

-

Reduces unplanned downtime and maintenance costs

Frequently Asked Questions (FAQ)

What types of sensors are compatible with the 3300/03-01-00 System Monitor?

Compatible with Bently Nevada 3300 series proximity probes and vibration sensors.

How many input channels does the system support?

Up to 8 sensor inputs.

What are the power supply requirements?

120/240 VAC, 50/60 Hz.

What are the system monitor’s dimensions?

Approximately 58.42mm × 203.2mm × 330.2mm.

Can the system outputs interface with plant control systems?

Yes, it provides relay and analog 4-20 mA outputs.

Is the system suitable for harsh industrial environments?

Yes, it is built for rugged industrial use.

Does the monitor support communication interfaces?

Optional serial or Ethernet interfaces are available.

What mounting options does the system have?

Standard 19-inch rack mount.

Can the alarm and trip points be configured?

Yes, they can be customized for specific machinery protection needs.

What industries typically use this system monitor?

Power generation, oil & gas, petrochemical, manufacturing, and heavy industries.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...