Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

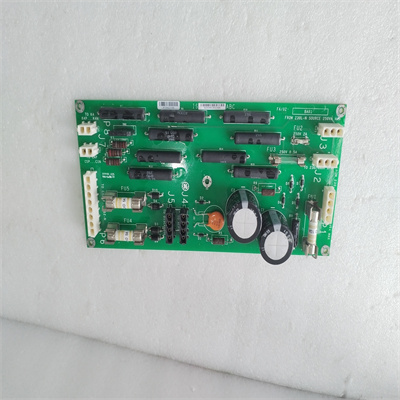

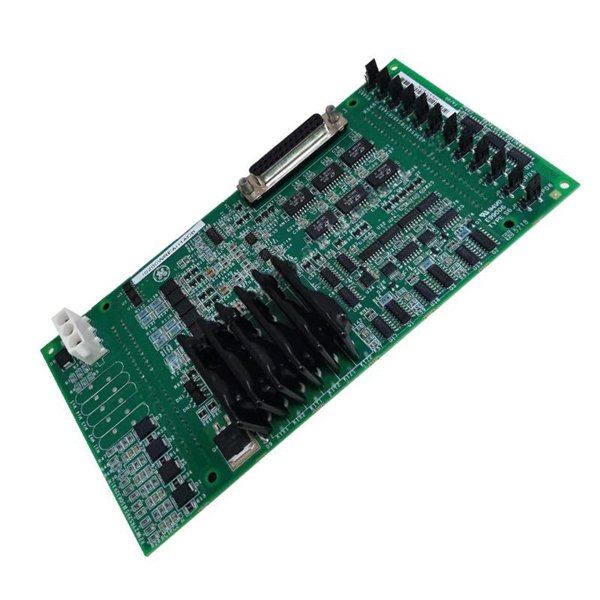

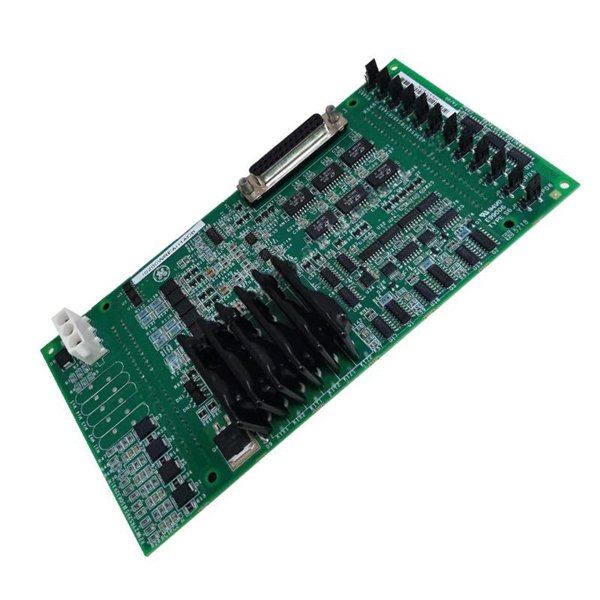

General Electric IS200WREAH1A Aero Trip Terminal Board

Manufacturer:GE

Product Number:IS200WREAH1A

Product Type:Aero Trip Terminal Board

Origin:USA

Dimensions:200 × 150 × 30 mm

Weight:0.3 kg

Views:60

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200WREAH1A is a robust and high-performance Aero Trip Terminal Board designed as a part of the Mark VI/VIe turbine control systems by General Electric (GE). Specifically engineered for turbine trip and protection functions, this terminal board plays a critical role in ensuring safe, rapid shutdown of gas turbines during abnormal or emergency conditions.

The WREAH1A board interfaces between the trip solenoids and the turbine control module, facilitating high-speed and reliable de-energizing of trip devices when required. It is used to monitor trip signals and issue trip commands to downstream electromechanical devices, ensuring protection of critical assets and human safety.

Built for aero-derivative turbine applications, this board supports high-integrity safety systems, helping to initiate turbine shutdown based on fault logic or operator intervention.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | IS200WREAH1A |

| Product Type | Aero Trip Terminal Board |

| Manufacturer | General Electric (GE) |

| System Compatibility | GE Mark VI / VIe Turbine Control Systems |

| Primary Function | Interface for turbine trip command and signal routing |

| Trip Signal Type | Dry contact relay outputs to solenoids or shutdown valves |

| Voltage Interface | 24–125 VDC (application dependent) |

| Channel Support | Multiple trip circuits for redundant control paths |

| Contact Rating | Configurable via control system (typically 2A @ 125 VDC) |

| Monitoring Support | Feedback loop for trip status confirmation |

| Terminal Type | Screw-type terminals for field wiring |

| Redundancy Support | Yes – supports dual path configurations |

| Diagnostic Capability | Integrated signal monitoring for fault detection |

| Operating Temperature | -30°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5%–95% non-condensing |

| Mounting Type | Panel or chassis mounted |

| Construction | Multi-layer PCB with conformal coating |

| Compliance | CE, RoHS, UL (application dependent) |

| Dimensions (L × W × H) | 200 × 150 × 30 mm |

| Weight | 0.3 kg |

| Part Status | Active / Field Replaceable Unit (FRU) |

Product Applications

The IS200WREAH1A terminal board is purpose-built for use in turbine trip and emergency shutdown circuits. It is a critical part of the protective control logic for the following systems:

Aero-derivative Gas Turbines

Steam Turbine Emergency Shutdown Systems

Mark VI/VIe Control Systems in Power Plants

Generator Overspeed and Overtemperature Shutdown Circuits

Redundant Trip Solenoid Interfaces

Emergency Fuel Shutoff Mechanisms

Product Advantages

Safety-Critical Design: Engineered to meet the rigorous demands of turbine trip systems in energy production.

High-Speed Response: Facilitates ultra-fast signal relay for immediate system shutdown in emergency events.

Redundancy Ready: Fully supports dual-path trip architecture, essential for high-integrity applications.

Durable Build: Built with conformal-coated, multi-layer PCB materials to withstand extreme industrial environments.

Field Serviceability: Designed as a Field Replaceable Unit (FRU), allowing quick replacement and minimized downtime.

Diagnostic Feedback: Enables the controller to verify trip circuit integrity, improving fault visibility and maintenance planning.

Flexible Configuration: Can be customized per turbine system specifications for voltage, relay logic, and interface type.

Secure Wiring: Terminal block design ensures firm field connections and simplified maintenance access.

FAQ

What type of signals does the IS200WREAH1A handle for trip execution?

The board operates using dry contact relay signals to actuate trip solenoids or shutoff valves.

Is the WREAH1A board suitable for redundant trip logic?

Yes, it supports multiple channels and can be configured in a dual-path setup for high-reliability systems.

Can the board detect failure or disconnect in trip circuits?

Yes, it features diagnostic feedback to the controller for open/short circuit detection.

Is the board directly connected to the turbine solenoids?

Yes, it interfaces directly with trip solenoids or fuel shutoff valves through terminal blocks.

What happens if one trip path fails in a redundant system?

The remaining path will remain functional, and the controller will log the fault for servicing.

How is the trip status confirmed by the controller?

Through feedback signals routed from the trip coil terminals back to the control processor.

Can the WREAH1A board be hot-swapped during operation?

No, it should only be replaced with system power off to avoid uncontrolled trips or damage.

Are there onboard relays integrated into the board?

The board typically uses external or controller-triggered relays; it primarily acts as an interface.

Does it support both AC and DC trip signals?

The board is generally used with DC circuits (24–125 VDC), depending on system design.

Is isolation provided between control signals and field trip devices?

Yes, electrical isolation is typically maintained to protect control logic from field faults.

General Electric IS200WREAH1A Aero Trip Terminal Board

Manufacturer:GE

Product Number:IS200WREAH1A

Product Type:Aero Trip Terminal Board

Origin:USA

Dimensions:200 × 150 × 30 mm

Weight:0.3 kg

Views:60

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200WREAH1A is a robust and high-performance Aero Trip Terminal Board designed as a part of the Mark VI/VIe turbine control systems by General Electric (GE). Specifically engineered for turbine trip and protection functions, this terminal board plays a critical role in ensuring safe, rapid shutdown of gas turbines during abnormal or emergency conditions.

The WREAH1A board interfaces between the trip solenoids and the turbine control module, facilitating high-speed and reliable de-energizing of trip devices when required. It is used to monitor trip signals and issue trip commands to downstream electromechanical devices, ensuring protection of critical assets and human safety.

Built for aero-derivative turbine applications, this board supports high-integrity safety systems, helping to initiate turbine shutdown based on fault logic or operator intervention.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | IS200WREAH1A |

| Product Type | Aero Trip Terminal Board |

| Manufacturer | General Electric (GE) |

| System Compatibility | GE Mark VI / VIe Turbine Control Systems |

| Primary Function | Interface for turbine trip command and signal routing |

| Trip Signal Type | Dry contact relay outputs to solenoids or shutdown valves |

| Voltage Interface | 24–125 VDC (application dependent) |

| Channel Support | Multiple trip circuits for redundant control paths |

| Contact Rating | Configurable via control system (typically 2A @ 125 VDC) |

| Monitoring Support | Feedback loop for trip status confirmation |

| Terminal Type | Screw-type terminals for field wiring |

| Redundancy Support | Yes – supports dual path configurations |

| Diagnostic Capability | Integrated signal monitoring for fault detection |

| Operating Temperature | -30°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5%–95% non-condensing |

| Mounting Type | Panel or chassis mounted |

| Construction | Multi-layer PCB with conformal coating |

| Compliance | CE, RoHS, UL (application dependent) |

| Dimensions (L × W × H) | 200 × 150 × 30 mm |

| Weight | 0.3 kg |

| Part Status | Active / Field Replaceable Unit (FRU) |

Product Applications

The IS200WREAH1A terminal board is purpose-built for use in turbine trip and emergency shutdown circuits. It is a critical part of the protective control logic for the following systems:

Aero-derivative Gas Turbines

Steam Turbine Emergency Shutdown Systems

Mark VI/VIe Control Systems in Power Plants

Generator Overspeed and Overtemperature Shutdown Circuits

Redundant Trip Solenoid Interfaces

Emergency Fuel Shutoff Mechanisms

Product Advantages

Safety-Critical Design: Engineered to meet the rigorous demands of turbine trip systems in energy production.

High-Speed Response: Facilitates ultra-fast signal relay for immediate system shutdown in emergency events.

Redundancy Ready: Fully supports dual-path trip architecture, essential for high-integrity applications.

Durable Build: Built with conformal-coated, multi-layer PCB materials to withstand extreme industrial environments.

Field Serviceability: Designed as a Field Replaceable Unit (FRU), allowing quick replacement and minimized downtime.

Diagnostic Feedback: Enables the controller to verify trip circuit integrity, improving fault visibility and maintenance planning.

Flexible Configuration: Can be customized per turbine system specifications for voltage, relay logic, and interface type.

Secure Wiring: Terminal block design ensures firm field connections and simplified maintenance access.

FAQ

What type of signals does the IS200WREAH1A handle for trip execution?

The board operates using dry contact relay signals to actuate trip solenoids or shutoff valves.

Is the WREAH1A board suitable for redundant trip logic?

Yes, it supports multiple channels and can be configured in a dual-path setup for high-reliability systems.

Can the board detect failure or disconnect in trip circuits?

Yes, it features diagnostic feedback to the controller for open/short circuit detection.

Is the board directly connected to the turbine solenoids?

Yes, it interfaces directly with trip solenoids or fuel shutoff valves through terminal blocks.

What happens if one trip path fails in a redundant system?

The remaining path will remain functional, and the controller will log the fault for servicing.

How is the trip status confirmed by the controller?

Through feedback signals routed from the trip coil terminals back to the control processor.

Can the WREAH1A board be hot-swapped during operation?

No, it should only be replaced with system power off to avoid uncontrolled trips or damage.

Are there onboard relays integrated into the board?

The board typically uses external or controller-triggered relays; it primarily acts as an interface.

Does it support both AC and DC trip signals?

The board is generally used with DC circuits (24–125 VDC), depending on system design.

Is isolation provided between control signals and field trip devices?

Yes, electrical isolation is typically maintained to protect control logic from field faults.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...