Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

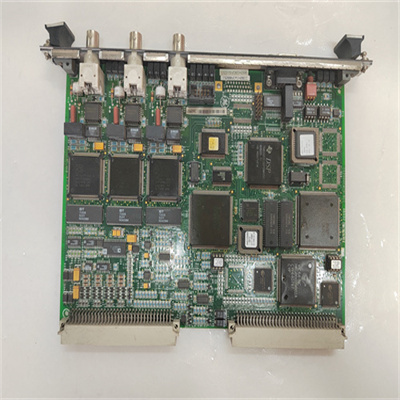

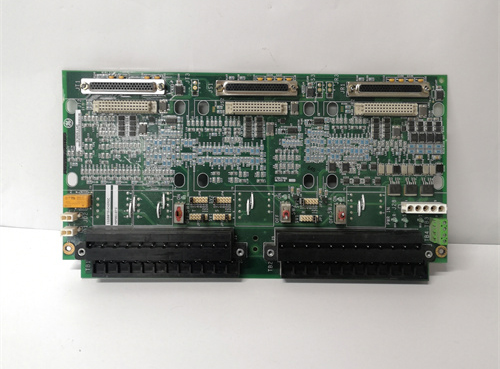

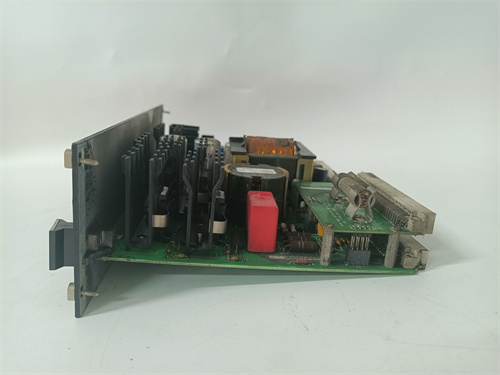

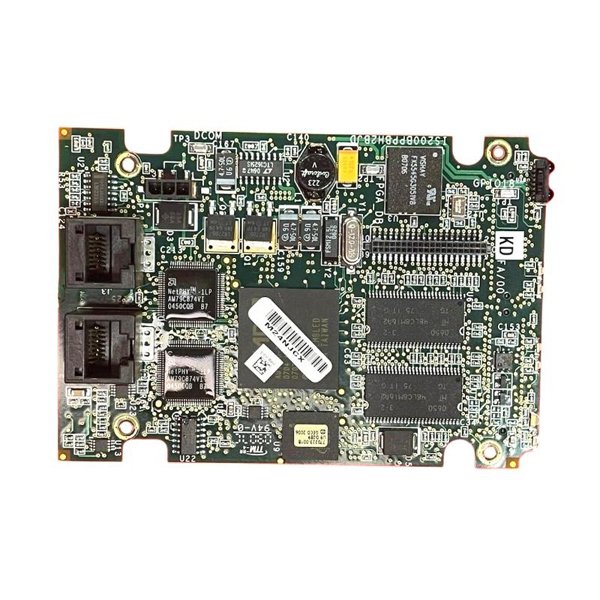

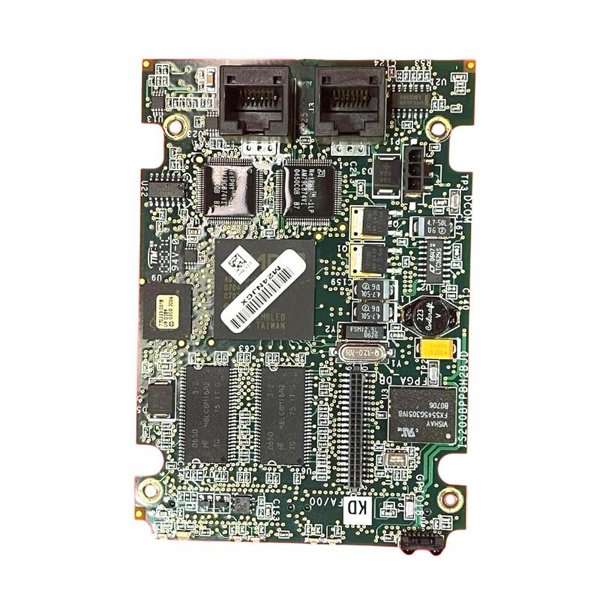

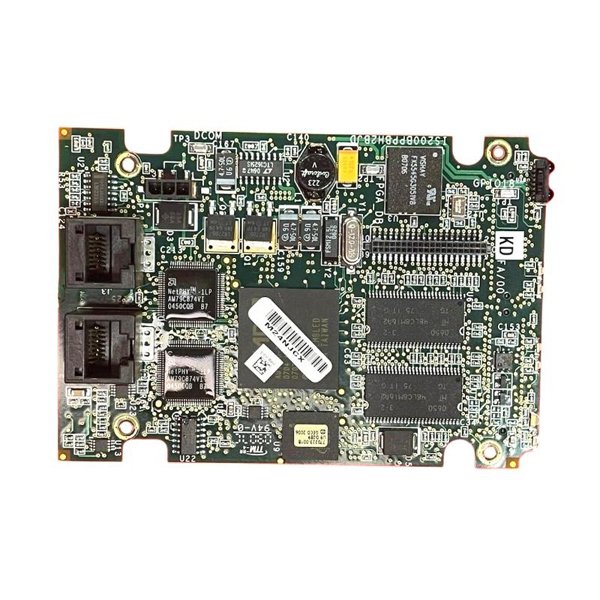

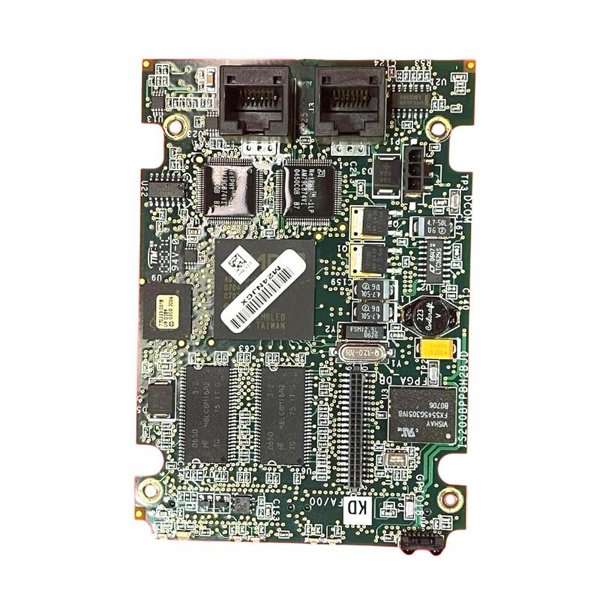

General Electric IS200BPPBH2B MK 6 Circuit Board

Manufacturer:GE

Product Number:IS200BPPBH2B

Product Type:MK 6 Circuit Board

Origin:USA

Dimensions:260 x 200 x 40 mm

Weight:0.85 kg

Views:54

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

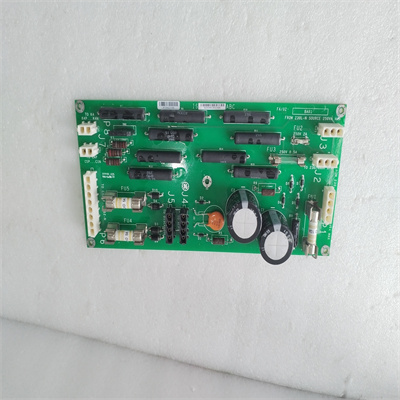

The GE IS200BPPBH2B is a high-performance printed circuit board (PCB) module developed for use within the Mark VI (MK VI) turbine control system, part of General Electric’s Speedtronic control platform for gas and steam turbines. As a part of this robust, scalable system architecture, the BPPB board functions primarily in power distribution and backplane interfacing, ensuring seamless communication between key modules and subsystems.

Designed with industrial durability and real-time responsiveness in mind, the IS200BPPBH2B acts as a central interface, distributing logic signals, control signals, and low-voltage power to adjacent system boards. Its integration into the MK VI system enhances system performance, supports high-reliability turbine operation, and streamlines diagnostics for critical infrastructure environments.

Backed by GE’s decades of innovation in automation and control technology, this board is a staple in both legacy and modernized turbine control systems.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | IS200BPPBH2B |

| Manufacturer | GE (General Electric) |

| Series | Mark VI Speedtronic |

| Function | Backplane Power Processor Board |

| System Compatibility | Mark VI Turbine Control System |

| Primary Role | Power Distribution and Signal Backplane Interface |

| Input Voltage | Supplied through MK VI rack (typically 24 VDC / 5 VDC) |

| Connectivity | Multiple PCB edge connectors (for I/O and control modules) |

| Mounting Type | Rack-mounted (vertical orientation) |

| Cooling Method | Convection (rack-enclosed airflow) |

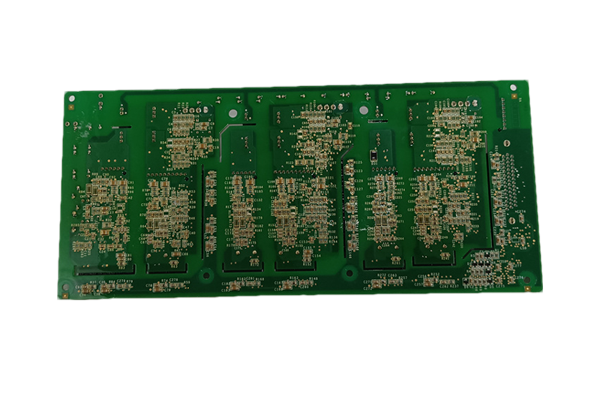

| On-Board Components | Capacitors, logic ICs, signal filters, fuses |

| PCB Layers | Multi-layer board for signal integrity |

| LED Indicators | Yes (power and status indicators) |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Humidity Range | 5% to 95% RH, non-condensing |

| Certifications | CE, UL, RoHS, CSA (in system context) |

| Dimensions (W x H x D) | 260 x 200 x 40 mm |

| Weight | 0.85 kg |

Applications

The IS200BPPBH2B board plays a crucial role in the overall control ecosystem of industrial turbines, helping ensure safe, synchronized operation and data flow. It is deployed in:

-

As a core part of the MK VI setup, it aids in signal distribution, power routing, and system health feedback.

Steam Turbine Automation

Coordinates control module interfacing for regulating steam flow and generator synchronization.

Industrial Power Generation

Used in facilities where turbines drive power generation, ensuring fault-tolerant logic processing and I/O connectivity.

Petrochemical and Refining Plants

Integrated in turbine-powered compressors and pump systems requiring high-uptime automation control.

Utilities and Municipal Power Stations

Helps maintain power distribution and communication within the turbine control framework for large-scale power producers.

Offshore and Marine Platforms

Deployed in harsh environmental conditions for turbine-driven systems on rigs and vessels.

Key Advantages

Robust System Integration

Seamlessly interfaces with other MK VI modules, simplifying system architecture.

High Signal Integrity

Multi-layer PCB design with signal shielding to reduce interference and noise.

Industrial Durability

Built to operate continuously in temperature-variable and vibration-prone environments.

Modular Flexibility

Can be easily swapped or upgraded within the Mark VI rack framework with minimal disruption.

Enhanced Diagnostics

Includes status LEDs and built-in feedback circuits for power and fault detection.

Backplane Efficiency

Consolidates power and communication distribution, reducing cabling and wiring complexity.

GE Certified Reliability

Designed and tested under stringent quality standards to meet mission-critical control demands.

Compact Form Factor

Despite its functionality, its compact design fits efficiently in MK VI racks.

Extended Service Life

Engineered for long-term deployment in power generation systems with limited maintenance needs.

Global Support Availability

Widely available via GE’s network and aftermarket suppliers for easy replacement and service continuity.

Frequently Asked Questions (FAQ)

1. What is the primary function of the IS200BPPBH2B board?

It acts as a power and signal distribution interface, connecting key components within the GE Mark VI turbine control system.

2. Can this board be used in both gas and steam turbine systems?

Yes, it is compatible with both types and is widely used across various industrial turbine configurations.

3. Is the IS200BPPBH2B board hot-swappable?

No. To prevent damage or data loss, power must be turned off before replacing the board.

4. What types of connectors are supported?

It features standard edge connectors designed for compatibility with adjacent Mark VI I/O and control modules.

5. How does it handle power distribution?

The board receives low-voltage input from the MK VI rack and routes it to various modules while providing signal backplane support.

6. Does it include any diagnostic features?

Yes. The board is equipped with LED indicators and onboard circuits to detect faults and power conditions.

7. What are the storage requirements for this board?

It should be stored in anti-static packaging at temperatures between -40°C and 85°C and humidity below 95% RH.

8. Is it necessary to configure or program the board after installation?

No manual configuration is required. It functions as a passive hardware interface within the MK VI system.

9. How can I tell if the board is malfunctioning?

Faults can be diagnosed through status LEDs and error codes from the main controller or interface station.

10. What kind of maintenance does the board require over time?

Routine visual inspections for dust accumulation, corrosion, or connector wear are typically sufficient. The board is designed for long-term service with minimal upkeep.

General Electric IS200BPPBH2B MK 6 Circuit Board

Manufacturer:GE

Product Number:IS200BPPBH2B

Product Type:MK 6 Circuit Board

Origin:USA

Dimensions:260 x 200 x 40 mm

Weight:0.85 kg

Views:54

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200BPPBH2B is a high-performance printed circuit board (PCB) module developed for use within the Mark VI (MK VI) turbine control system, part of General Electric’s Speedtronic control platform for gas and steam turbines. As a part of this robust, scalable system architecture, the BPPB board functions primarily in power distribution and backplane interfacing, ensuring seamless communication between key modules and subsystems.

Designed with industrial durability and real-time responsiveness in mind, the IS200BPPBH2B acts as a central interface, distributing logic signals, control signals, and low-voltage power to adjacent system boards. Its integration into the MK VI system enhances system performance, supports high-reliability turbine operation, and streamlines diagnostics for critical infrastructure environments.

Backed by GE’s decades of innovation in automation and control technology, this board is a staple in both legacy and modernized turbine control systems.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | IS200BPPBH2B |

| Manufacturer | GE (General Electric) |

| Series | Mark VI Speedtronic |

| Function | Backplane Power Processor Board |

| System Compatibility | Mark VI Turbine Control System |

| Primary Role | Power Distribution and Signal Backplane Interface |

| Input Voltage | Supplied through MK VI rack (typically 24 VDC / 5 VDC) |

| Connectivity | Multiple PCB edge connectors (for I/O and control modules) |

| Mounting Type | Rack-mounted (vertical orientation) |

| Cooling Method | Convection (rack-enclosed airflow) |

| On-Board Components | Capacitors, logic ICs, signal filters, fuses |

| PCB Layers | Multi-layer board for signal integrity |

| LED Indicators | Yes (power and status indicators) |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Humidity Range | 5% to 95% RH, non-condensing |

| Certifications | CE, UL, RoHS, CSA (in system context) |

| Dimensions (W x H x D) | 260 x 200 x 40 mm |

| Weight | 0.85 kg |

Applications

The IS200BPPBH2B board plays a crucial role in the overall control ecosystem of industrial turbines, helping ensure safe, synchronized operation and data flow. It is deployed in:

-

As a core part of the MK VI setup, it aids in signal distribution, power routing, and system health feedback.

Steam Turbine Automation

Coordinates control module interfacing for regulating steam flow and generator synchronization.

Industrial Power Generation

Used in facilities where turbines drive power generation, ensuring fault-tolerant logic processing and I/O connectivity.

Petrochemical and Refining Plants

Integrated in turbine-powered compressors and pump systems requiring high-uptime automation control.

Utilities and Municipal Power Stations

Helps maintain power distribution and communication within the turbine control framework for large-scale power producers.

Offshore and Marine Platforms

Deployed in harsh environmental conditions for turbine-driven systems on rigs and vessels.

Key Advantages

Robust System Integration

Seamlessly interfaces with other MK VI modules, simplifying system architecture.

High Signal Integrity

Multi-layer PCB design with signal shielding to reduce interference and noise.

Industrial Durability

Built to operate continuously in temperature-variable and vibration-prone environments.

Modular Flexibility

Can be easily swapped or upgraded within the Mark VI rack framework with minimal disruption.

Enhanced Diagnostics

Includes status LEDs and built-in feedback circuits for power and fault detection.

Backplane Efficiency

Consolidates power and communication distribution, reducing cabling and wiring complexity.

GE Certified Reliability

Designed and tested under stringent quality standards to meet mission-critical control demands.

Compact Form Factor

Despite its functionality, its compact design fits efficiently in MK VI racks.

Extended Service Life

Engineered for long-term deployment in power generation systems with limited maintenance needs.

Global Support Availability

Widely available via GE’s network and aftermarket suppliers for easy replacement and service continuity.

Frequently Asked Questions (FAQ)

1. What is the primary function of the IS200BPPBH2B board?

It acts as a power and signal distribution interface, connecting key components within the GE Mark VI turbine control system.

2. Can this board be used in both gas and steam turbine systems?

Yes, it is compatible with both types and is widely used across various industrial turbine configurations.

3. Is the IS200BPPBH2B board hot-swappable?

No. To prevent damage or data loss, power must be turned off before replacing the board.

4. What types of connectors are supported?

It features standard edge connectors designed for compatibility with adjacent Mark VI I/O and control modules.

5. How does it handle power distribution?

The board receives low-voltage input from the MK VI rack and routes it to various modules while providing signal backplane support.

6. Does it include any diagnostic features?

Yes. The board is equipped with LED indicators and onboard circuits to detect faults and power conditions.

7. What are the storage requirements for this board?

It should be stored in anti-static packaging at temperatures between -40°C and 85°C and humidity below 95% RH.

8. Is it necessary to configure or program the board after installation?

No manual configuration is required. It functions as a passive hardware interface within the MK VI system.

9. How can I tell if the board is malfunctioning?

Faults can be diagnosed through status LEDs and error codes from the main controller or interface station.

10. What kind of maintenance does the board require over time?

Routine visual inspections for dust accumulation, corrosion, or connector wear are typically sufficient. The board is designed for long-term service with minimal upkeep.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...