Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

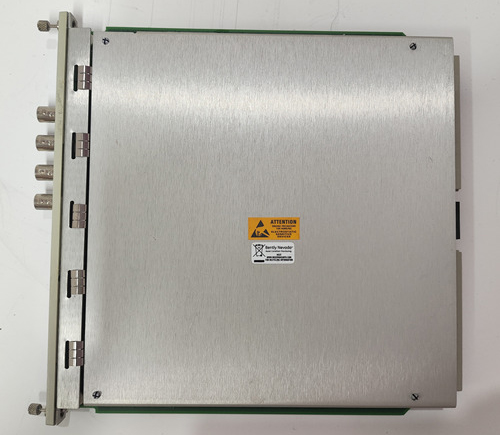

Bently Nevada 330102-00-60-10-01-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330102-00-60-10-01-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1 m

Weight :0.323 kg

Views:37

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330102-00-60-10-01-05 3300 XL 8 mm Proximity Probe is a high-performance non-contact sensor designed for precise vibration and shaft position measurements in rotating machinery. As part of the widely trusted 3300 XL series, this probe provides reliable data acquisition under demanding industrial conditions, supporting machinery protection systems and predictive maintenance programs. It is engineered to meet API 670 requirements and is fully compatible with Bently Nevada monitoring systems.

This probe is particularly known for its durability in harsh environments, offering excellent immunity to electrical noise, stable output over a wide temperature range, and accurate signal transmission over long cable lengths. It is designed for compatibility with proximity transducers and extension cables, ensuring a complete and accurate measurement chain.

Technical Parameters

| Parameter | Specification |

|---|---|

| Model Number | 330102-00-60-10-01-05 |

| Series | 3300 XL 8 mm Proximity Probe |

| Probe Tip Diameter | 8 mm |

| Linear Range | 2 mm (80 mils) |

| Sensitivity | -200 mV/mil (±5%) |

| Frequency Response | DC to 10 kHz (±3 dB) |

| Operating Temperature | -35 °C to +177 °C |

| Storage Temperature | -40 °C to +200 °C |

| Maximum Cable Length | Up to 9 m with matching system |

| Material | Stainless Steel Probe Body |

| Insulation Resistance | >10^9 ohms |

| Weight | 0.323 kg |

| Total Length | 1 m |

| Mounting Thread | M10 x 1.0 or compatible thread type |

| Connector Type | Mini-coaxial connector, 90° angle |

Product Applications

The 330102-00-60-10-01-05 proximity probe is widely used in turbomachinery monitoring and protection systems. Its applications include:

-

Monitoring radial and axial shaft vibration.

-

Detecting shaft position relative to bearing housings.

-

Overspeed and rotor dynamic studies in turbines, compressors, and pumps.

-

Condition monitoring in generators, motors, and gearboxes.

-

Integration with machinery protection systems for early fault detection.

-

Application in petrochemical, power generation, marine, and heavy industrial sectors.

By providing accurate real-time data, this probe supports predictive maintenance strategies, reducing unplanned downtime and extending equipment service life.

Product Advantages

High Reliability – Engineered to withstand harsh industrial environments with stable operation.

API 670 Compliance – Ensures adherence to industry standards for machinery protection.

Extended Operating Range – Wide linear response and frequency capability for versatile measurement.

Electromagnetic Noise Immunity – Provides accurate signals even in electrically noisy environments.

Compatibility – Fully interchangeable with other Bently Nevada 3300 XL components, ensuring seamless integration.

Durability – Robust stainless steel design, resistant to vibration, temperature extremes, and corrosive conditions.

Precision Measurement – Consistent sensitivity and calibration accuracy improve diagnostic confidence.

FAQ

Q1: How does the probe maintain accuracy in high-temperature environments?

A1: The probe is constructed with temperature-stable materials and calibration that compensates for expansion effects, ensuring consistent sensitivity up to +177 °C.

Q2: Can the probe be used with extension cables longer than 9 m?

A2: The probe is calibrated for specific cable lengths. Using longer cables may affect signal integrity and is not recommended without factory re-calibration.

Q3: What is the typical signal output when measuring shaft displacement?

A3: The probe outputs a voltage signal proportional to shaft displacement, typically -200 mV per mil of displacement.

Q4: Is the probe immune to oil film interference in journal bearings?

A4: Yes, the probe is designed to penetrate oil films and maintain accurate measurement of shaft-to-probe distance.

Q5: How does the probe perform in electrically noisy environments?

A5: The coaxial cable design and shielding provide strong noise immunity, maintaining accuracy in environments with high EMI.

Q6: Can the probe be installed in both axial and radial configurations?

A6: Yes, it can be mounted to measure shaft vibration radially or thrust position axially, depending on monitoring requirements.

Q7: What happens if the probe is not calibrated with the correct cable length?

A7: Mismatch in probe, extension cable, and proximitor length can cause errors in sensitivity and linearity. Correct matching is essential.

Q8: Does the probe require periodic recalibration?

A8: Factory calibration is highly stable. Recalibration is typically only needed after cable replacement or system modification.

Q9: How does the probe respond to very high-frequency vibrations?

A9: It maintains effective response up to 10 kHz, suitable for most rotating machinery monitoring applications.

Q10: Can this probe detect shaft rub or misalignment events?

A10: Yes, the probe can capture sudden displacement spikes or changes in vibration patterns that indicate rubs, misalignment, or rotor instability.

Bently Nevada 330102-00-60-10-01-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330102-00-60-10-01-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1 m

Weight :0.323 kg

Views:37

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330102-00-60-10-01-05 3300 XL 8 mm Proximity Probe is a high-performance non-contact sensor designed for precise vibration and shaft position measurements in rotating machinery. As part of the widely trusted 3300 XL series, this probe provides reliable data acquisition under demanding industrial conditions, supporting machinery protection systems and predictive maintenance programs. It is engineered to meet API 670 requirements and is fully compatible with Bently Nevada monitoring systems.

This probe is particularly known for its durability in harsh environments, offering excellent immunity to electrical noise, stable output over a wide temperature range, and accurate signal transmission over long cable lengths. It is designed for compatibility with proximity transducers and extension cables, ensuring a complete and accurate measurement chain.

Technical Parameters

| Parameter | Specification |

|---|---|

| Model Number | 330102-00-60-10-01-05 |

| Series | 3300 XL 8 mm Proximity Probe |

| Probe Tip Diameter | 8 mm |

| Linear Range | 2 mm (80 mils) |

| Sensitivity | -200 mV/mil (±5%) |

| Frequency Response | DC to 10 kHz (±3 dB) |

| Operating Temperature | -35 °C to +177 °C |

| Storage Temperature | -40 °C to +200 °C |

| Maximum Cable Length | Up to 9 m with matching system |

| Material | Stainless Steel Probe Body |

| Insulation Resistance | >10^9 ohms |

| Weight | 0.323 kg |

| Total Length | 1 m |

| Mounting Thread | M10 x 1.0 or compatible thread type |

| Connector Type | Mini-coaxial connector, 90° angle |

Product Applications

The 330102-00-60-10-01-05 proximity probe is widely used in turbomachinery monitoring and protection systems. Its applications include:

-

Monitoring radial and axial shaft vibration.

-

Detecting shaft position relative to bearing housings.

-

Overspeed and rotor dynamic studies in turbines, compressors, and pumps.

-

Condition monitoring in generators, motors, and gearboxes.

-

Integration with machinery protection systems for early fault detection.

-

Application in petrochemical, power generation, marine, and heavy industrial sectors.

By providing accurate real-time data, this probe supports predictive maintenance strategies, reducing unplanned downtime and extending equipment service life.

Product Advantages

High Reliability – Engineered to withstand harsh industrial environments with stable operation.

API 670 Compliance – Ensures adherence to industry standards for machinery protection.

Extended Operating Range – Wide linear response and frequency capability for versatile measurement.

Electromagnetic Noise Immunity – Provides accurate signals even in electrically noisy environments.

Compatibility – Fully interchangeable with other Bently Nevada 3300 XL components, ensuring seamless integration.

Durability – Robust stainless steel design, resistant to vibration, temperature extremes, and corrosive conditions.

Precision Measurement – Consistent sensitivity and calibration accuracy improve diagnostic confidence.

FAQ

Q1: How does the probe maintain accuracy in high-temperature environments?

A1: The probe is constructed with temperature-stable materials and calibration that compensates for expansion effects, ensuring consistent sensitivity up to +177 °C.

Q2: Can the probe be used with extension cables longer than 9 m?

A2: The probe is calibrated for specific cable lengths. Using longer cables may affect signal integrity and is not recommended without factory re-calibration.

Q3: What is the typical signal output when measuring shaft displacement?

A3: The probe outputs a voltage signal proportional to shaft displacement, typically -200 mV per mil of displacement.

Q4: Is the probe immune to oil film interference in journal bearings?

A4: Yes, the probe is designed to penetrate oil films and maintain accurate measurement of shaft-to-probe distance.

Q5: How does the probe perform in electrically noisy environments?

A5: The coaxial cable design and shielding provide strong noise immunity, maintaining accuracy in environments with high EMI.

Q6: Can the probe be installed in both axial and radial configurations?

A6: Yes, it can be mounted to measure shaft vibration radially or thrust position axially, depending on monitoring requirements.

Q7: What happens if the probe is not calibrated with the correct cable length?

A7: Mismatch in probe, extension cable, and proximitor length can cause errors in sensitivity and linearity. Correct matching is essential.

Q8: Does the probe require periodic recalibration?

A8: Factory calibration is highly stable. Recalibration is typically only needed after cable replacement or system modification.

Q9: How does the probe respond to very high-frequency vibrations?

A9: It maintains effective response up to 10 kHz, suitable for most rotating machinery monitoring applications.

Q10: Can this probe detect shaft rub or misalignment events?

A10: Yes, the probe can capture sudden displacement spikes or changes in vibration patterns that indicate rubs, misalignment, or rotor instability.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...