Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

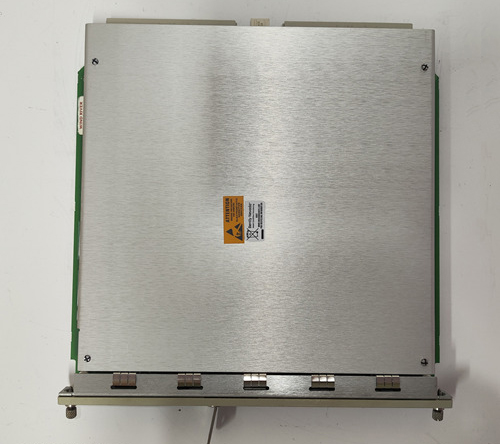

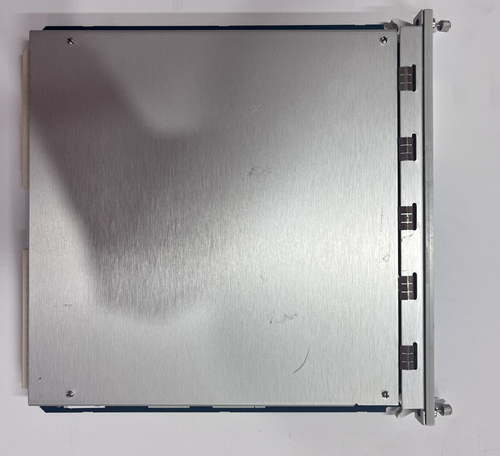

Bently Nevada 9200-01-20-10-00 Dual-line velocity seismic sensor

Manufacturer:Bently Nevada

Product Number: 9200-01-20-10-00

Product Type:Dual-line velocity seismic sensor

Origin:USA

Sensor diameter:41.4mm

Weight :0.3 kg

Views:68

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 9200-01-20-10-00 is a dual-line velocity seismic sensor designed for precision vibration monitoring in industrial rotating machinery. This sensor is part of Bently Nevada’s proven 9200 series, engineered to deliver high-accuracy measurements in harsh environments where reliability is essential. It converts mechanical vibrations into proportional electrical signals, enabling predictive maintenance and early fault detection.

Built with robust materials, the sensor withstands extreme temperatures, high humidity, and mechanical shock. It is especially suited for applications in turbines, compressors, pumps, and large electric motors. Its precise performance and long service life make it a trusted choice in condition monitoring systems worldwide.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 9200-01-20-10-00 |

| Sensor Type | Dual-Line Velocity Seismic Sensor |

| Frequency Response | 10 Hz to 1,000 Hz |

| Sensitivity | 100 mV/in/sec ±5% |

| Output Type | Voltage |

| Operating Temperature Range | -40°C to +100°C |

| Storage Temperature Range | -50°C to +120°C |

| Mounting Type | Stud Mount |

| Housing Material | Stainless Steel |

| Protection Rating | IP65 |

| Sensor diameter | 41.4mm |

| Weight | 0.3 kg |

| Cable Connection | 2-wire, shielded |

| Power Supply Requirement | 18–30 VDC |

| Shock Limit | 500 g peak |

| Humidity Range | 0–95% non-condensing |

Applications

The Bently Nevada 9200-01-20-10-00 is widely used in critical machinery monitoring across various industries, including:

Power Generation – Turbine vibration monitoring in gas, steam, and hydroelectric plants.

Oil & Gas – Compressor and pump condition monitoring in refineries and offshore platforms.

Manufacturing – Monitoring motors, gearboxes, and conveyors in heavy industrial operations.

Marine Engineering – Vibration tracking for propulsion systems and auxiliary equipment.

Mining Operations – Equipment health monitoring for crushers, mills, and processing machinery.

Chemical Processing – Ensuring stable operation of critical rotating pumps and mixers.

Product Advantages

High Measurement Accuracy – Delivers consistent readings across a broad frequency range, ensuring reliable analysis.

Rugged Construction – Stainless steel housing with IP65 rating provides excellent protection in harsh environments.

Wide Operating Temperature Range – Suitable for extreme climate and process conditions.

Dual-Line Output – Improves signal clarity and compatibility with advanced monitoring systems.

Low Maintenance – Designed for long-term service with minimal calibration requirements.

Global Compatibility – Integrates seamlessly with Bently Nevada 3500 and other monitoring platforms.

Predictive Maintenance Capability – Helps identify developing faults before costly failures occur.

Compact Size – Easy to install in tight spaces without compromising performance.

Frequently Asked Questions (FAQ)

Q1: What is the main function of the Bently Nevada 9200-01-20-10-00?

A1: It measures machine vibration velocity and converts it into an electrical signal for monitoring and analysis.

Q2: Can it be used outdoors?

A2: Yes, the IP65 rating ensures dust and water resistance, making it suitable for outdoor installations.

Q3: Is calibration required frequently?

A3: No, it is factory calibrated and requires minimal recalibration under normal conditions.

Q4: Can this sensor detect early bearing failures?

A4: Yes, it can detect vibration changes that indicate bearing wear or imbalance before serious damage occurs.

Q5: What cable type should I use?

A5: A shielded, two-wire cable is recommended to minimize electrical noise.

Q6: Does it require special mounting tools?

A6: Standard stud-mount tools are sufficient; however, proper torque settings should be followed.

Q7: What monitoring systems is it compatible with?

A7: It integrates with Bently Nevada 3500 series and most industrial vibration monitoring platforms.

Q8: Can it be used in explosive environments?

A8: Only if paired with appropriate intrinsically safe barriers and certified enclosures.

Q9: How long is the typical service life?

A9: With proper installation and operation, it can exceed 5 years of reliable service.

Q10: Is it sensitive to mounting orientation?

A10: While it can operate in various orientations, vertical mounting often ensures optimal performance.

Bently Nevada 9200-01-20-10-00 Dual-line velocity seismic sensor

Manufacturer:Bently Nevada

Product Number: 9200-01-20-10-00

Product Type:Dual-line velocity seismic sensor

Origin:USA

Sensor diameter:41.4mm

Weight :0.3 kg

Views:68

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 9200-01-20-10-00 is a dual-line velocity seismic sensor designed for precision vibration monitoring in industrial rotating machinery. This sensor is part of Bently Nevada’s proven 9200 series, engineered to deliver high-accuracy measurements in harsh environments where reliability is essential. It converts mechanical vibrations into proportional electrical signals, enabling predictive maintenance and early fault detection.

Built with robust materials, the sensor withstands extreme temperatures, high humidity, and mechanical shock. It is especially suited for applications in turbines, compressors, pumps, and large electric motors. Its precise performance and long service life make it a trusted choice in condition monitoring systems worldwide.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 9200-01-20-10-00 |

| Sensor Type | Dual-Line Velocity Seismic Sensor |

| Frequency Response | 10 Hz to 1,000 Hz |

| Sensitivity | 100 mV/in/sec ±5% |

| Output Type | Voltage |

| Operating Temperature Range | -40°C to +100°C |

| Storage Temperature Range | -50°C to +120°C |

| Mounting Type | Stud Mount |

| Housing Material | Stainless Steel |

| Protection Rating | IP65 |

| Sensor diameter | 41.4mm |

| Weight | 0.3 kg |

| Cable Connection | 2-wire, shielded |

| Power Supply Requirement | 18–30 VDC |

| Shock Limit | 500 g peak |

| Humidity Range | 0–95% non-condensing |

Applications

The Bently Nevada 9200-01-20-10-00 is widely used in critical machinery monitoring across various industries, including:

Power Generation – Turbine vibration monitoring in gas, steam, and hydroelectric plants.

Oil & Gas – Compressor and pump condition monitoring in refineries and offshore platforms.

Manufacturing – Monitoring motors, gearboxes, and conveyors in heavy industrial operations.

Marine Engineering – Vibration tracking for propulsion systems and auxiliary equipment.

Mining Operations – Equipment health monitoring for crushers, mills, and processing machinery.

Chemical Processing – Ensuring stable operation of critical rotating pumps and mixers.

Product Advantages

High Measurement Accuracy – Delivers consistent readings across a broad frequency range, ensuring reliable analysis.

Rugged Construction – Stainless steel housing with IP65 rating provides excellent protection in harsh environments.

Wide Operating Temperature Range – Suitable for extreme climate and process conditions.

Dual-Line Output – Improves signal clarity and compatibility with advanced monitoring systems.

Low Maintenance – Designed for long-term service with minimal calibration requirements.

Global Compatibility – Integrates seamlessly with Bently Nevada 3500 and other monitoring platforms.

Predictive Maintenance Capability – Helps identify developing faults before costly failures occur.

Compact Size – Easy to install in tight spaces without compromising performance.

Frequently Asked Questions (FAQ)

Q1: What is the main function of the Bently Nevada 9200-01-20-10-00?

A1: It measures machine vibration velocity and converts it into an electrical signal for monitoring and analysis.

Q2: Can it be used outdoors?

A2: Yes, the IP65 rating ensures dust and water resistance, making it suitable for outdoor installations.

Q3: Is calibration required frequently?

A3: No, it is factory calibrated and requires minimal recalibration under normal conditions.

Q4: Can this sensor detect early bearing failures?

A4: Yes, it can detect vibration changes that indicate bearing wear or imbalance before serious damage occurs.

Q5: What cable type should I use?

A5: A shielded, two-wire cable is recommended to minimize electrical noise.

Q6: Does it require special mounting tools?

A6: Standard stud-mount tools are sufficient; however, proper torque settings should be followed.

Q7: What monitoring systems is it compatible with?

A7: It integrates with Bently Nevada 3500 series and most industrial vibration monitoring platforms.

Q8: Can it be used in explosive environments?

A8: Only if paired with appropriate intrinsically safe barriers and certified enclosures.

Q9: How long is the typical service life?

A9: With proper installation and operation, it can exceed 5 years of reliable service.

Q10: Is it sensitive to mounting orientation?

A10: While it can operate in various orientations, vertical mounting often ensures optimal performance.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...