Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

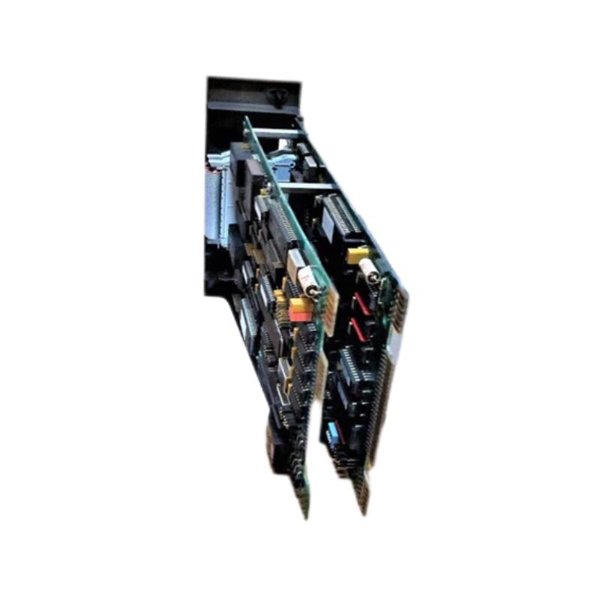

ABB Bailey PBA200 PHCBRCPBA20000 Process Bus Adaptor

Manufacturer:ABB Bailey

Product Number:PBA200 PHCBRCPBA20000

Product Type:Process Bus Adaptor

Origin:Sweden

Dimensions:215 × 127 × 38 mm

Weight:0.231 kg

Views:27

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB Bailey PBA200 PHCBRCPBA20000 is a Process Bus Adaptor (PBA) that plays a vital role in the integration of legacy Bailey control systems—such as the INFI 90, Net 90, and Symphony DCS—with high-speed process networks. Acting as a communications bridge, the PBA200 facilitates the smooth flow of data between the process control modules and other I/O subsystems, field instrumentation, and controllers over standardized process buses.

It is designed to manage real-time data exchange in distributed control environments, ensuring compatibility with existing ABB Bailey infrastructure while introducing improved speed, efficiency, and protocol standardization. This device enables system expansion, modernization, and enhanced communication performance without needing a full replacement of legacy hardware, making it ideal for brownfield sites and long-running process facilities.

Thanks to its robust construction and firmware-level adaptability, the PBA200 is a key enabler for digital transformation initiatives within established process automation systems, helping to extend operational life and reduce total cost of ownership.

Product Specifications

| Parameter | Description |

|---|---|

| Model | PBA200 PHCBRCPBA20000 |

| Product Type | Process Bus Adaptor |

| Function | Interface for process bus communications between system modules |

| System Compatibility | INFI 90, Net 90, Symphony DCS |

| Bus Standards Supported | Bailey proprietary buses, Symphony process bus protocols |

| Data Rate | Typically up to 2.5 Mbps (depending on configuration) |

| Communication Ports | Dual-port process bus connectors |

| Mounting Style | Rack-mounted or panel-installed |

| Redundancy Support | Yes (via dual-bus operation) |

| Power Supply | 5 VDC from system backplane |

| Firmware Upgradeable | Yes (via ABB configuration tools) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95%, non-condensing |

| Material | Industrial-grade circuit board with metal faceplate |

| Dimensions (W x H x D) | 215 × 127 × 38 mm |

| Weight | 0.231 kg |

| Certifications | CE, UL, RoHS compliant |

Product Applications

The ABB Bailey PBA200 Process Bus Adaptor is primarily used in critical infrastructure and process industries that require reliable communication across different system layers. Its deployment enables real-time command and feedback from field equipment to control logic processors. Common applications include:

Power Generation – Facilitates high-speed data exchange between turbine controllers and field devices.

Petrochemical and Oil & Gas Facilities – Connects remote process stations to control rooms with secure and synchronized data transmission.

Water and Wastewater Treatment Plants – Ensures real-time input/output feedback for pump control, filtration, and SCADA systems.

Chemical Processing – Bridges analog/digital I/O with plant controllers and advanced analytics engines.

Pulp & Paper Mills – Coordinates control modules across various stages of material processing and automation.

Mining and Metallurgy – Links safety systems, motor control centers, and monitoring nodes to the central DCS.

Product Advantages

Legacy System Integration: Seamlessly connects INFI 90 and Net 90 systems with modern bus infrastructures, extending system life.

Dual Bus Support: Enables redundancy for mission-critical applications, ensuring communication continuity during failures.

Scalable Network Communication: Allows integration of additional field devices without overhauling the entire control network.

Reduced Downtime Risk: Enhances communication reliability and isolation, helping prevent cascading system failures.

Firmware Flexibility: Upgradeable firmware accommodates evolving protocol requirements without replacing hardware.

High Signal Integrity: Designed with industrial-grade shielding and connectors to ensure signal fidelity in harsh environments.

Compact Form Factor: Saves panel space and supports easy retrofitting into existing DCS racks.

No External Power Required: Receives power through the system backplane, simplifying installation.

ABB Technical Support: Backed by ABB’s global network for lifecycle support and spares management.

Cost-Efficient Modernization: Enables phased migration toward Industry 4.0 without fully replacing legacy systems.

Frequently Asked Questions (FAQ)

What is the primary function of the PBA200 adaptor?

The PBA200 serves as a communication bridge between the Bailey control modules and the process bus, ensuring fast and accurate data transmission within the control system.

Can this device be used in dual-redundant process bus configurations?

Yes. The PBA200 supports dual-bus operation, providing redundancy and fault tolerance in high-availability environments.

What type of communication protocols does the PBA200 support?

It supports ABB proprietary bus protocols used in INFI 90, Net 90, and Symphony systems, ensuring compatibility with legacy infrastructure.

Is firmware upgrade possible without removing the unit?

Yes. Firmware can be upgraded in-place using ABB configuration tools, ensuring minimal system interruption.

Can the PBA200 operate in hazardous or outdoor environments?

The module itself is designed for installation within protective cabinets. For hazardous locations, use in certified enclosures is required.

What is the maximum recommended cable length for process bus connectivity?

It depends on the bus protocol and environment but typically ranges up to 1200 meters with shielded twisted-pair cable.

Does the PBA200 require an external power supply?

No. It draws regulated 5 VDC power from the system backplane, eliminating the need for dedicated power wiring.

What happens if one of the buses fails during operation?

In dual-bus mode, the system automatically switches to the secondary bus to maintain communication without data loss.

Can this unit be used with modern ABB 800xA or AC 800M systems?

It is not directly compatible but can be used in hybrid setups with proper gateways or signal translators between legacy and modern systems.

How often should the PBA200 be maintained or inspected?

Annual inspection is recommended to check bus connection integrity, firmware status, and general system health, especially in high-vibration or dusty environments.

ABB Bailey PBA200 PHCBRCPBA20000 Process Bus Adaptor

Manufacturer:ABB Bailey

Product Number:PBA200 PHCBRCPBA20000

Product Type:Process Bus Adaptor

Origin:Sweden

Dimensions:215 × 127 × 38 mm

Weight:0.231 kg

Views:27

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB Bailey PBA200 PHCBRCPBA20000 is a Process Bus Adaptor (PBA) that plays a vital role in the integration of legacy Bailey control systems—such as the INFI 90, Net 90, and Symphony DCS—with high-speed process networks. Acting as a communications bridge, the PBA200 facilitates the smooth flow of data between the process control modules and other I/O subsystems, field instrumentation, and controllers over standardized process buses.

It is designed to manage real-time data exchange in distributed control environments, ensuring compatibility with existing ABB Bailey infrastructure while introducing improved speed, efficiency, and protocol standardization. This device enables system expansion, modernization, and enhanced communication performance without needing a full replacement of legacy hardware, making it ideal for brownfield sites and long-running process facilities.

Thanks to its robust construction and firmware-level adaptability, the PBA200 is a key enabler for digital transformation initiatives within established process automation systems, helping to extend operational life and reduce total cost of ownership.

Product Specifications

| Parameter | Description |

|---|---|

| Model | PBA200 PHCBRCPBA20000 |

| Product Type | Process Bus Adaptor |

| Function | Interface for process bus communications between system modules |

| System Compatibility | INFI 90, Net 90, Symphony DCS |

| Bus Standards Supported | Bailey proprietary buses, Symphony process bus protocols |

| Data Rate | Typically up to 2.5 Mbps (depending on configuration) |

| Communication Ports | Dual-port process bus connectors |

| Mounting Style | Rack-mounted or panel-installed |

| Redundancy Support | Yes (via dual-bus operation) |

| Power Supply | 5 VDC from system backplane |

| Firmware Upgradeable | Yes (via ABB configuration tools) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95%, non-condensing |

| Material | Industrial-grade circuit board with metal faceplate |

| Dimensions (W x H x D) | 215 × 127 × 38 mm |

| Weight | 0.231 kg |

| Certifications | CE, UL, RoHS compliant |

Product Applications

The ABB Bailey PBA200 Process Bus Adaptor is primarily used in critical infrastructure and process industries that require reliable communication across different system layers. Its deployment enables real-time command and feedback from field equipment to control logic processors. Common applications include:

Power Generation – Facilitates high-speed data exchange between turbine controllers and field devices.

Petrochemical and Oil & Gas Facilities – Connects remote process stations to control rooms with secure and synchronized data transmission.

Water and Wastewater Treatment Plants – Ensures real-time input/output feedback for pump control, filtration, and SCADA systems.

Chemical Processing – Bridges analog/digital I/O with plant controllers and advanced analytics engines.

Pulp & Paper Mills – Coordinates control modules across various stages of material processing and automation.

Mining and Metallurgy – Links safety systems, motor control centers, and monitoring nodes to the central DCS.

Product Advantages

Legacy System Integration: Seamlessly connects INFI 90 and Net 90 systems with modern bus infrastructures, extending system life.

Dual Bus Support: Enables redundancy for mission-critical applications, ensuring communication continuity during failures.

Scalable Network Communication: Allows integration of additional field devices without overhauling the entire control network.

Reduced Downtime Risk: Enhances communication reliability and isolation, helping prevent cascading system failures.

Firmware Flexibility: Upgradeable firmware accommodates evolving protocol requirements without replacing hardware.

High Signal Integrity: Designed with industrial-grade shielding and connectors to ensure signal fidelity in harsh environments.

Compact Form Factor: Saves panel space and supports easy retrofitting into existing DCS racks.

No External Power Required: Receives power through the system backplane, simplifying installation.

ABB Technical Support: Backed by ABB’s global network for lifecycle support and spares management.

Cost-Efficient Modernization: Enables phased migration toward Industry 4.0 without fully replacing legacy systems.

Frequently Asked Questions (FAQ)

What is the primary function of the PBA200 adaptor?

The PBA200 serves as a communication bridge between the Bailey control modules and the process bus, ensuring fast and accurate data transmission within the control system.

Can this device be used in dual-redundant process bus configurations?

Yes. The PBA200 supports dual-bus operation, providing redundancy and fault tolerance in high-availability environments.

What type of communication protocols does the PBA200 support?

It supports ABB proprietary bus protocols used in INFI 90, Net 90, and Symphony systems, ensuring compatibility with legacy infrastructure.

Is firmware upgrade possible without removing the unit?

Yes. Firmware can be upgraded in-place using ABB configuration tools, ensuring minimal system interruption.

Can the PBA200 operate in hazardous or outdoor environments?

The module itself is designed for installation within protective cabinets. For hazardous locations, use in certified enclosures is required.

What is the maximum recommended cable length for process bus connectivity?

It depends on the bus protocol and environment but typically ranges up to 1200 meters with shielded twisted-pair cable.

Does the PBA200 require an external power supply?

No. It draws regulated 5 VDC power from the system backplane, eliminating the need for dedicated power wiring.

What happens if one of the buses fails during operation?

In dual-bus mode, the system automatically switches to the secondary bus to maintain communication without data loss.

Can this unit be used with modern ABB 800xA or AC 800M systems?

It is not directly compatible but can be used in hybrid setups with proper gateways or signal translators between legacy and modern systems.

How often should the PBA200 be maintained or inspected?

Annual inspection is recommended to check bus connection integrity, firmware status, and general system health, especially in high-vibration or dusty environments.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...