Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

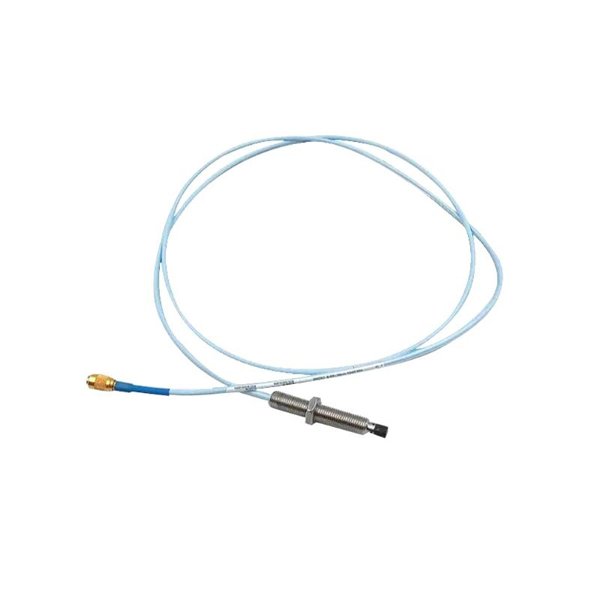

Bently Nevada 330171-24-32-20-02-05 3300 5mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330171-24-32-20-02-05

Product Type:3300 5mm Proximity Probe

Origin:USA

Total Length:2.0 meter

Weight:0.646kg

Views:18

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330171-24-32-20-02-05 proximity probe is a high-precision sensor designed for measuring vibration and displacement in rotating machinery. This 5mm probe from the 3300 series is specifically engineered for reliable performance in challenging industrial environments, offering exceptional accuracy and durability. It is commonly used to monitor the health of critical equipment like pumps, compressors, motors, and turbines.

This proximity probe works in conjunction with Bently Nevada’s 3300 XL Proximitor sensors, providing real-time feedback to operators about the operational status of machinery. By continuously monitoring vibration levels and displacement, the 3300 series proximity probes help detect mechanical imbalances, misalignments, and other faults, enabling predictive maintenance and reducing the likelihood of unexpected failures.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 330171-24-32-20-02-05 |

| Probe Type | 5mm Proximity Probe |

| Total Length | 2.0 meters |

| Weight | 0.646 kg |

| Unthreaded Length | 0.0 inches (0.0 mm) |

| Housing Length | 3.0 inches (76.2 mm) |

| Connector Type | Miniature Coaxial ClickLoc Connector |

| Operating Temperature | -40°C to +120°C |

| Output Signal | 4-20 mA (proportional to vibration or displacement) |

| Power Requirements | -17.5 VDC to -26 VDC, max current 12 mA |

| Linear Range | 2 mm (80 mils) |

| Probe Resistance | 7.45 ± 0.50 Ω (2.0 m length) |

| Target Material | AISI 4140 Steel |

| Mounting | Standard or custom mounting options available |

Applications

The 330171-24-32-20-02-05 5mm proximity probe is used in the following applications:

-

Vibration Monitoring – Essential for detecting mechanical imbalances, misalignments, and other faults in rotating equipment.

-

Condition Monitoring – Continuously tracks the condition of critical machinery like motors, compressors, and pumps.

-

Predictive Maintenance – Allows operators to predict and prevent potential machine failures by identifying early warning signs.

-

Axial Displacement Measurement – Monitors axial movement of rotating machinery to ensure proper alignment and performance.

-

Keyphasor Signal Measurement – Provides reliable keyphasor signals for synchronous measurements of rotational speed and alignment.

-

Compact Installations – The probe’s design is ideal for tight spaces and installations where size and space are constraints.

Advantages

-

High Precision – Provides highly accurate measurements of vibration and displacement to ensure optimal equipment performance.

-

Compact and Robust – Designed for installation in tight spaces, the probe is built to withstand harsh industrial environments.

-

Wide Operating Temperature Range – Functions in temperatures as low as -40°C and as high as +120°C, making it ideal for diverse applications.

-

Easy Integration – The probe is fully compatible with 3300 XL Proximitor sensors, simplifying installation and system integration.

-

Durable and Reliable – Made from high-quality materials, the probe delivers reliable performance and long-lasting durability.

-

Versatile Applications – Suitable for a wide range of industries, including power generation, manufacturing, and petrochemicals.

-

Electromagnetic Interference Resistance – The design ensures stable operation even in environments with significant electrical interference.

-

Cost-Effective Maintenance – By enabling predictive maintenance, the probe helps prevent costly downtime and repairs.

-

Improved Safety – By continuously monitoring equipment, the probe helps detect potential issues before they lead to machine failures or accidents.

-

No Separate Calibration Needed – The probe is fully interchangeable with other 3300 series components without requiring additional calibration.

FAQ

Q1: What type of output signal does this probe provide?

A1: The 330171-24-32-20-02-05 proximity probe provides a 4-20 mA output signal that is proportional to vibration or displacement measurements.

Q2: What is the operating temperature range of the probe?

A2: The probe can operate in temperatures ranging from -40°C to +120°C.

Q3: Is separate calibration required for this proximity probe?

A3: No, the 330171-24-32-20-02-05 probe is fully interchangeable with other 3300 series components and does not require separate calibration.

Q4: What is the linear measurement range of the probe?

A4: The linear measurement range of the probe is 2 mm (80 mils).

Q5: Can this probe be used for axial displacement measurements?

A5: Yes, the 330171-24-32-20-02-05 probe is designed to measure axial displacement in rotating machinery.

Q6: What are the power requirements for this probe?

A6: The probe requires a power supply of -17.5 VDC to -26 VDC, with a maximum current of 12 mA.

Q7: How is the probe mounted?

A7: The probe can be mounted using standard or custom mounting options, depending on the application and installation requirements.

Q8: What is the target material of the probe?

A8: The probe is designed to measure displacement on AISI 4140 steel targets.

Q9: Can this probe be used for high-vibration environments?

A9: Yes, this probe is ideal for high-vibration environments and is commonly used for monitoring large industrial machinery such as turbines and compressors.

Q10: Does the probe have resistance to electromagnetic interference?

A10: Yes, the 330171-24-32-20-02-05 probe is designed to minimize the impact of electromagnetic interference (EMI), ensuring stable operation in electrically noisy environments.

Bently Nevada 330171-24-32-20-02-05 3300 5mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330171-24-32-20-02-05

Product Type:3300 5mm Proximity Probe

Origin:USA

Total Length:2.0 meter

Weight:0.646kg

Views:18

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330171-24-32-20-02-05 proximity probe is a high-precision sensor designed for measuring vibration and displacement in rotating machinery. This 5mm probe from the 3300 series is specifically engineered for reliable performance in challenging industrial environments, offering exceptional accuracy and durability. It is commonly used to monitor the health of critical equipment like pumps, compressors, motors, and turbines.

This proximity probe works in conjunction with Bently Nevada’s 3300 XL Proximitor sensors, providing real-time feedback to operators about the operational status of machinery. By continuously monitoring vibration levels and displacement, the 3300 series proximity probes help detect mechanical imbalances, misalignments, and other faults, enabling predictive maintenance and reducing the likelihood of unexpected failures.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 330171-24-32-20-02-05 |

| Probe Type | 5mm Proximity Probe |

| Total Length | 2.0 meters |

| Weight | 0.646 kg |

| Unthreaded Length | 0.0 inches (0.0 mm) |

| Housing Length | 3.0 inches (76.2 mm) |

| Connector Type | Miniature Coaxial ClickLoc Connector |

| Operating Temperature | -40°C to +120°C |

| Output Signal | 4-20 mA (proportional to vibration or displacement) |

| Power Requirements | -17.5 VDC to -26 VDC, max current 12 mA |

| Linear Range | 2 mm (80 mils) |

| Probe Resistance | 7.45 ± 0.50 Ω (2.0 m length) |

| Target Material | AISI 4140 Steel |

| Mounting | Standard or custom mounting options available |

Applications

The 330171-24-32-20-02-05 5mm proximity probe is used in the following applications:

-

Vibration Monitoring – Essential for detecting mechanical imbalances, misalignments, and other faults in rotating equipment.

-

Condition Monitoring – Continuously tracks the condition of critical machinery like motors, compressors, and pumps.

-

Predictive Maintenance – Allows operators to predict and prevent potential machine failures by identifying early warning signs.

-

Axial Displacement Measurement – Monitors axial movement of rotating machinery to ensure proper alignment and performance.

-

Keyphasor Signal Measurement – Provides reliable keyphasor signals for synchronous measurements of rotational speed and alignment.

-

Compact Installations – The probe’s design is ideal for tight spaces and installations where size and space are constraints.

Advantages

-

High Precision – Provides highly accurate measurements of vibration and displacement to ensure optimal equipment performance.

-

Compact and Robust – Designed for installation in tight spaces, the probe is built to withstand harsh industrial environments.

-

Wide Operating Temperature Range – Functions in temperatures as low as -40°C and as high as +120°C, making it ideal for diverse applications.

-

Easy Integration – The probe is fully compatible with 3300 XL Proximitor sensors, simplifying installation and system integration.

-

Durable and Reliable – Made from high-quality materials, the probe delivers reliable performance and long-lasting durability.

-

Versatile Applications – Suitable for a wide range of industries, including power generation, manufacturing, and petrochemicals.

-

Electromagnetic Interference Resistance – The design ensures stable operation even in environments with significant electrical interference.

-

Cost-Effective Maintenance – By enabling predictive maintenance, the probe helps prevent costly downtime and repairs.

-

Improved Safety – By continuously monitoring equipment, the probe helps detect potential issues before they lead to machine failures or accidents.

-

No Separate Calibration Needed – The probe is fully interchangeable with other 3300 series components without requiring additional calibration.

FAQ

Q1: What type of output signal does this probe provide?

A1: The 330171-24-32-20-02-05 proximity probe provides a 4-20 mA output signal that is proportional to vibration or displacement measurements.

Q2: What is the operating temperature range of the probe?

A2: The probe can operate in temperatures ranging from -40°C to +120°C.

Q3: Is separate calibration required for this proximity probe?

A3: No, the 330171-24-32-20-02-05 probe is fully interchangeable with other 3300 series components and does not require separate calibration.

Q4: What is the linear measurement range of the probe?

A4: The linear measurement range of the probe is 2 mm (80 mils).

Q5: Can this probe be used for axial displacement measurements?

A5: Yes, the 330171-24-32-20-02-05 probe is designed to measure axial displacement in rotating machinery.

Q6: What are the power requirements for this probe?

A6: The probe requires a power supply of -17.5 VDC to -26 VDC, with a maximum current of 12 mA.

Q7: How is the probe mounted?

A7: The probe can be mounted using standard or custom mounting options, depending on the application and installation requirements.

Q8: What is the target material of the probe?

A8: The probe is designed to measure displacement on AISI 4140 steel targets.

Q9: Can this probe be used for high-vibration environments?

A9: Yes, this probe is ideal for high-vibration environments and is commonly used for monitoring large industrial machinery such as turbines and compressors.

Q10: Does the probe have resistance to electromagnetic interference?

A10: Yes, the 330171-24-32-20-02-05 probe is designed to minimize the impact of electromagnetic interference (EMI), ensuring stable operation in electrically noisy environments.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...