Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

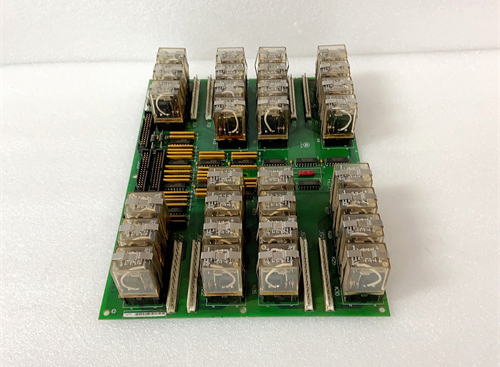

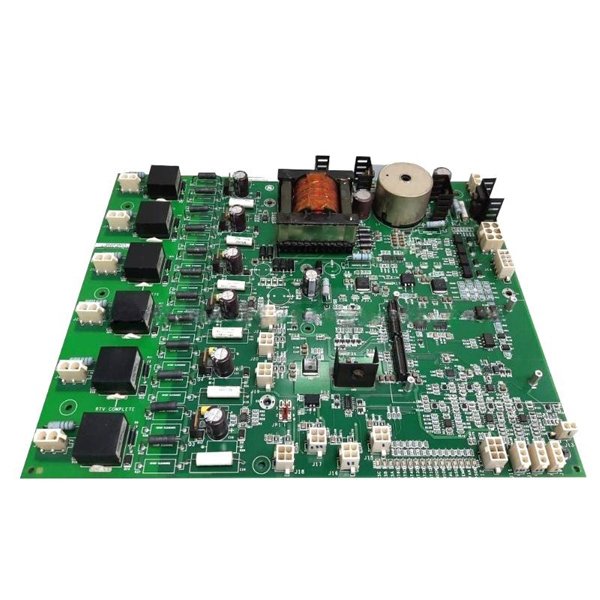

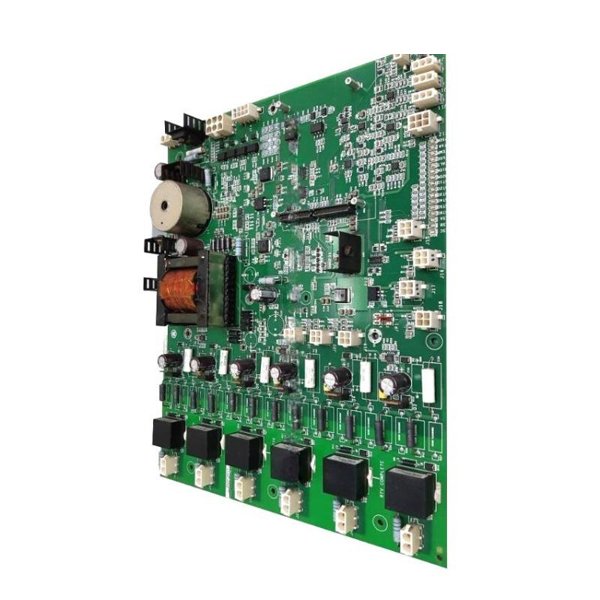

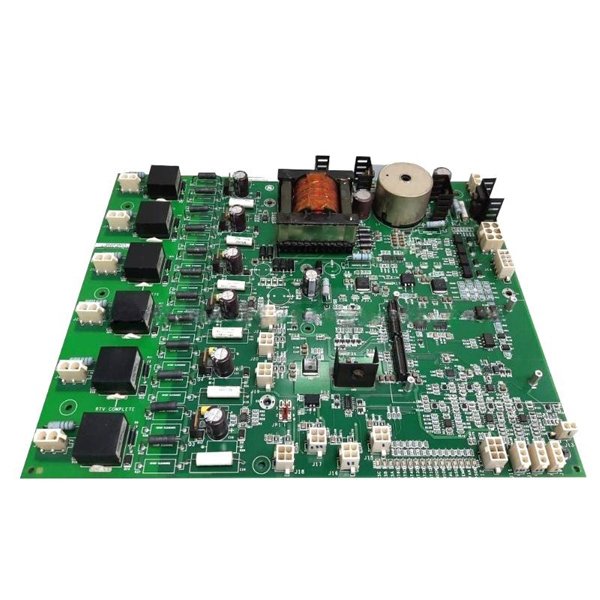

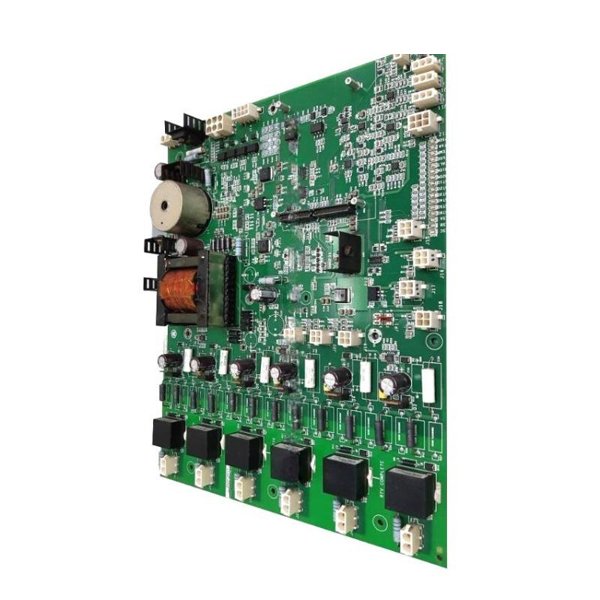

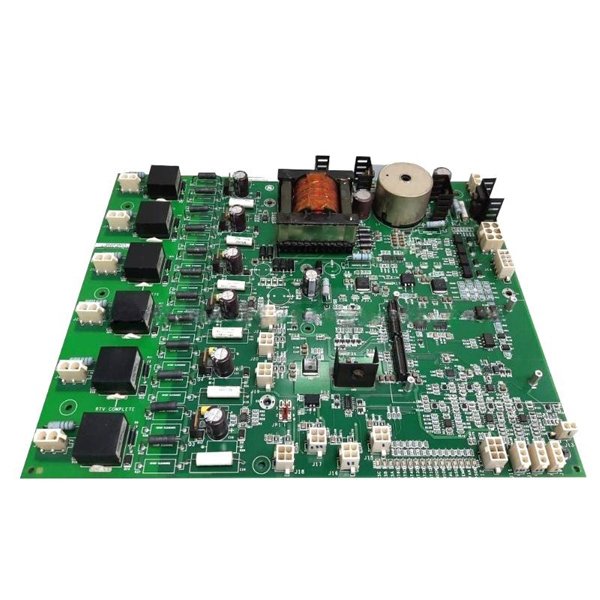

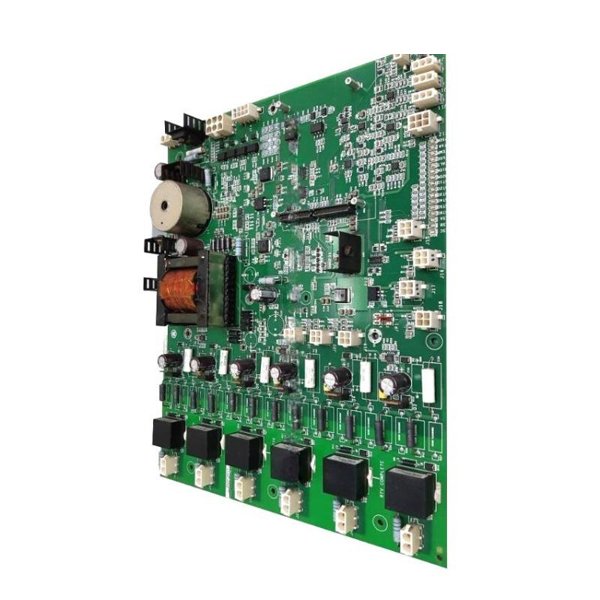

General Electric IS200EBRGH2A Exciter Bridge Interface Board

Manufacturer:GE

Product Number:IS200EBRGH2A

Product Type:Exciter Bridge Interface Board

Origin:USA

Dimensions:38 × 330 × 250 mm

Weight:0.907 kg

Views:31

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200EBRGH2A is a specialized Exciter Bridge Interface Board designed for integration into GE’s EX2100 excitation control system, which is commonly used in gas and steam turbine generator applications. Its main role is to facilitate the interface between the excitation power bridge and the controller, allowing for real-time control, monitoring, and protection of the exciter bridge components.

This board supports critical functions such as gate drive signal communication, bridge health monitoring, overvoltage protection signals, and temperature sensing. It is engineered to manage signal interfacing between power electronics and the EX2100 control system under high-reliability, high-availability conditions.

As part of GE’s Mark VIe and EX2100 product lines, the IS200EBRGH2A meets the needs of power generation applications that demand accuracy, fast response, and rugged design. It is extensively deployed in synchronous generator excitation systems around the world.

Technical Specifications

| Parameter | Details |

|---|---|

| Part Number | IS200EBRGH2A |

| Product Type | Exciter Bridge Interface Board |

| System Compatibility | EX2100 Excitation Control System, Mark VIe |

| Communication Interfaces | Fiber-optic (for gate commands and feedback) |

| Primary Function | Bridge interface for gate control & diagnostics |

| Temperature Monitoring | Yes – supports thermal sensors |

| Gate Driver Support | SCR/IGBT-based bridges (depending on configuration) |

| Status Feedback | Bridge health, overtemp, fault signals |

| Input Power Requirements | Supplied via exciter system backplane |

| Redundancy Support | Yes (in redundant EX2100 configurations) |

| PCB Layers | Multilayer, conformal-coated |

| Mounting Type | Rack or chassis mount (inside exciter cabinet) |

| Cooling Method | Convection or cabinet ventilation |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5%–95%, non-condensing |

| Dimensions (W × H × D) | 38 × 330 × 250 mm |

| Weight | 0.907 kg |

| Certifications | CE, RoHS compliant, UL recognized |

Application Scenarios

The GE IS200EBRGH2A Exciter Bridge Interface Board is critical in applications where precise control of generator excitation is required. It is used in:

-

Thermal Power Plants: Managing the excitation bridge in large-scale synchronous generators.

-

Hydropower Stations: Ensuring voltage regulation in hydro turbines.

-

Industrial Generation: Used in steel plants, cement factories, and chemical plants with captive power systems.

-

Utility Power Grid Support: Helps provide voltage support and VAR control.

-

Renewable Integration: Integrated with renewable systems for grid voltage stability.

-

Critical Infrastructure: Backup power systems in airports, hospitals, and data centers.

Product Advantages

-

Optimized for EX2100: Tailored to work flawlessly within GE’s EX2100 excitation control architecture.

-

Reliable Gate Signal Transmission: Supports high-speed, fiber-optic-based gate drive communications.

-

Robust Environmental Design: Withstands wide temperature and humidity ranges.

-

Modular Architecture: Supports easy replacement and field maintenance.

-

Fault Detection and Diagnostics: Provides real-time bridge health data to the controller.

-

Thermal Monitoring Support: Monitors SCR or IGBT junction temperatures for predictive maintenance.

-

High Voltage Isolation: Ensures safe separation between control and power circuits.

-

UL and CE Certified: Complies with global industrial standards.

Frequently Asked Questions (FAQ)

1. What is the function of the IS200EBRGH2A board?

It acts as the interface between the EX2100 exciter controller and the power bridge, transmitting gate signals and receiving feedback such as temperature and fault data.

2. Is the board compatible with all EX2100 systems?

It is primarily used in specific EX2100 configurations. Compatibility depends on the exciter hardware setup and control system revision. It’s best to confirm with system documentation or GE support.

3. Does this board handle fiber-optic communication?

Yes, the board uses fiber-optic links to send and receive signals from the gate driver circuits, ensuring electrical isolation and fast data transmission.

4. How is the board powered?

It receives power through the system backplane when installed in the exciter cabinet. No external power supply is needed.

5. Can the board be replaced without shutting down the system?

No, the board is part of the critical power control interface and should only be replaced during a controlled shutdown.

6. What kind of feedback does the board provide to the controller?

It monitors bridge conditions such as over-temperature, gate signal status, and fault signals, and sends this data back to the controller for diagnostics and protection.

7. Does the board support SCR and IGBT technologies?

Yes, depending on system configuration, the board supports both SCR and IGBT-based bridge interfaces.

8. How do I know if the board has failed?

Typical symptoms include missing gate signals, repeated bridge faults, or diagnostic alarms in the control system. Visual inspection and system logs can help pinpoint issues.

9. What environment is the board designed for?

The board is built for industrial environments, with a temperature range from -30°C to +65°C and high humidity tolerance. It is also conformal-coated for protection against dust and corrosion.

10. Is conformal coating included for harsh environments?

Yes, it comes conformal-coated for protection against dust, humidity, and corrosive gases.

General Electric IS200EBRGH2A Exciter Bridge Interface Board

Manufacturer:GE

Product Number:IS200EBRGH2A

Product Type:Exciter Bridge Interface Board

Origin:USA

Dimensions:38 × 330 × 250 mm

Weight:0.907 kg

Views:31

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200EBRGH2A is a specialized Exciter Bridge Interface Board designed for integration into GE’s EX2100 excitation control system, which is commonly used in gas and steam turbine generator applications. Its main role is to facilitate the interface between the excitation power bridge and the controller, allowing for real-time control, monitoring, and protection of the exciter bridge components.

This board supports critical functions such as gate drive signal communication, bridge health monitoring, overvoltage protection signals, and temperature sensing. It is engineered to manage signal interfacing between power electronics and the EX2100 control system under high-reliability, high-availability conditions.

As part of GE’s Mark VIe and EX2100 product lines, the IS200EBRGH2A meets the needs of power generation applications that demand accuracy, fast response, and rugged design. It is extensively deployed in synchronous generator excitation systems around the world.

Technical Specifications

| Parameter | Details |

|---|---|

| Part Number | IS200EBRGH2A |

| Product Type | Exciter Bridge Interface Board |

| System Compatibility | EX2100 Excitation Control System, Mark VIe |

| Communication Interfaces | Fiber-optic (for gate commands and feedback) |

| Primary Function | Bridge interface for gate control & diagnostics |

| Temperature Monitoring | Yes – supports thermal sensors |

| Gate Driver Support | SCR/IGBT-based bridges (depending on configuration) |

| Status Feedback | Bridge health, overtemp, fault signals |

| Input Power Requirements | Supplied via exciter system backplane |

| Redundancy Support | Yes (in redundant EX2100 configurations) |

| PCB Layers | Multilayer, conformal-coated |

| Mounting Type | Rack or chassis mount (inside exciter cabinet) |

| Cooling Method | Convection or cabinet ventilation |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5%–95%, non-condensing |

| Dimensions (W × H × D) | 38 × 330 × 250 mm |

| Weight | 0.907 kg |

| Certifications | CE, RoHS compliant, UL recognized |

Application Scenarios

The GE IS200EBRGH2A Exciter Bridge Interface Board is critical in applications where precise control of generator excitation is required. It is used in:

-

Thermal Power Plants: Managing the excitation bridge in large-scale synchronous generators.

-

Hydropower Stations: Ensuring voltage regulation in hydro turbines.

-

Industrial Generation: Used in steel plants, cement factories, and chemical plants with captive power systems.

-

Utility Power Grid Support: Helps provide voltage support and VAR control.

-

Renewable Integration: Integrated with renewable systems for grid voltage stability.

-

Critical Infrastructure: Backup power systems in airports, hospitals, and data centers.

Product Advantages

-

Optimized for EX2100: Tailored to work flawlessly within GE’s EX2100 excitation control architecture.

-

Reliable Gate Signal Transmission: Supports high-speed, fiber-optic-based gate drive communications.

-

Robust Environmental Design: Withstands wide temperature and humidity ranges.

-

Modular Architecture: Supports easy replacement and field maintenance.

-

Fault Detection and Diagnostics: Provides real-time bridge health data to the controller.

-

Thermal Monitoring Support: Monitors SCR or IGBT junction temperatures for predictive maintenance.

-

High Voltage Isolation: Ensures safe separation between control and power circuits.

-

UL and CE Certified: Complies with global industrial standards.

Frequently Asked Questions (FAQ)

1. What is the function of the IS200EBRGH2A board?

It acts as the interface between the EX2100 exciter controller and the power bridge, transmitting gate signals and receiving feedback such as temperature and fault data.

2. Is the board compatible with all EX2100 systems?

It is primarily used in specific EX2100 configurations. Compatibility depends on the exciter hardware setup and control system revision. It’s best to confirm with system documentation or GE support.

3. Does this board handle fiber-optic communication?

Yes, the board uses fiber-optic links to send and receive signals from the gate driver circuits, ensuring electrical isolation and fast data transmission.

4. How is the board powered?

It receives power through the system backplane when installed in the exciter cabinet. No external power supply is needed.

5. Can the board be replaced without shutting down the system?

No, the board is part of the critical power control interface and should only be replaced during a controlled shutdown.

6. What kind of feedback does the board provide to the controller?

It monitors bridge conditions such as over-temperature, gate signal status, and fault signals, and sends this data back to the controller for diagnostics and protection.

7. Does the board support SCR and IGBT technologies?

Yes, depending on system configuration, the board supports both SCR and IGBT-based bridge interfaces.

8. How do I know if the board has failed?

Typical symptoms include missing gate signals, repeated bridge faults, or diagnostic alarms in the control system. Visual inspection and system logs can help pinpoint issues.

9. What environment is the board designed for?

The board is built for industrial environments, with a temperature range from -30°C to +65°C and high humidity tolerance. It is also conformal-coated for protection against dust and corrosion.

10. Is conformal coating included for harsh environments?

Yes, it comes conformal-coated for protection against dust, humidity, and corrosive gases.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...