Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

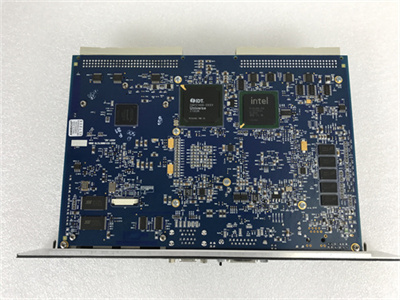

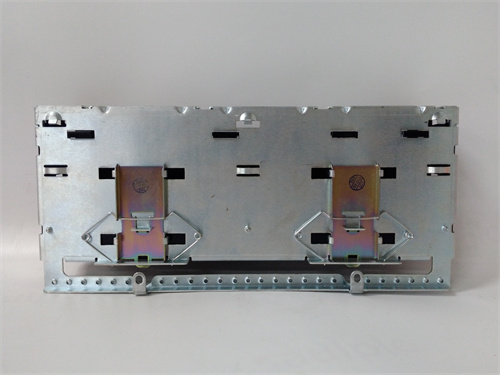

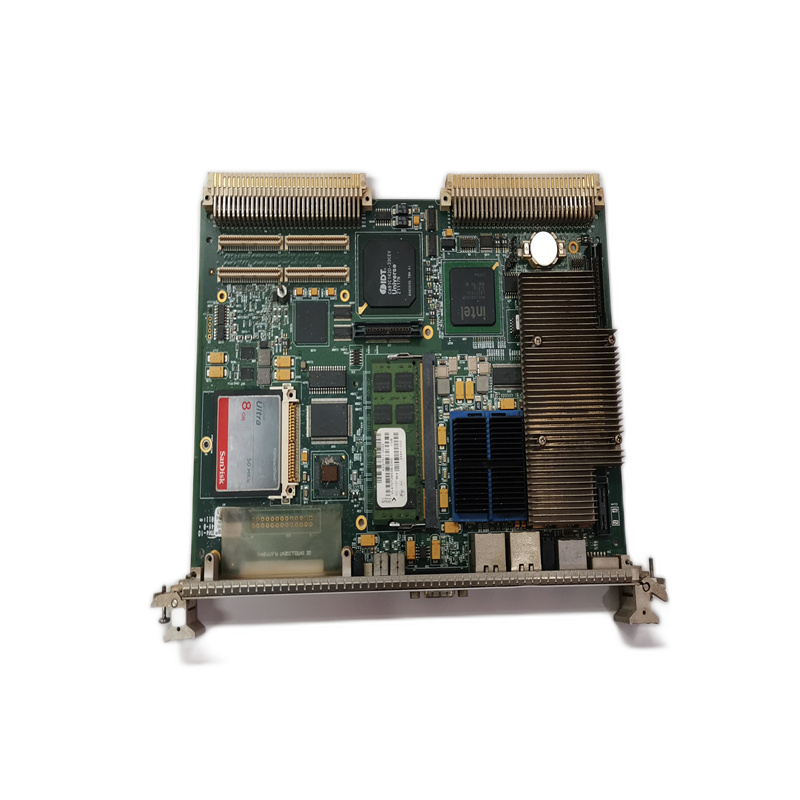

General Electric IC693MAR590 I/O Module

Manufacturer:GE

Product Number:IC693MAR590

Product Type:I/O Module

Origin:USA

Dimensions:100 x 50 x 110 mm

Weight:0.2 kg

Views:45

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IC693MAR590 I/O Module is a versatile 16-point combination module designed for use with the GE Fanuc Series 90-30 Programmable Logic Controller (PLC) systems. As a mixed I/O module, it offers both digital inputs and relay outputs within a single compact unit, providing a flexible and space-saving solution for industrial automation applications.

The IC693MAR590 is ideal for systems where there is a need to read input signals (such as switches, sensors, or pushbuttons) and control output devices (such as relays, solenoids, and indicator lamps) in one module. This combination helps reduce the number of modules needed in a rack, simplifies wiring, and lowers installation costs.

The module is engineered for reliable operation in demanding environments. It offers excellent isolation between input and output channels, noise immunity, and fast response times. Designed to seamlessly integrate into GE Series 90-30 PLCs, it supports a wide range of industrial applications, from simple machine control to complex process automation.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | IC693MAR590 |

| Product Type | 16-Point Combination I/O Module (8 In / 8 Out) |

| Input Channels | 8 Digital Inputs (AC/DC compatible) |

| Input Voltage Range | 0–30 VDC or 0–132 VAC |

| Input Current @ 120 VAC | 10 mA typical |

| Input Current @ 24 VDC | 7 mA typical |

| Output Channels | 8 Relay Outputs (Form A, SPST-NO) |

| Output Voltage Rating | 5–30 VDC or 5–250 VAC |

| Output Current Rating | 2 A max per point (resistive load) |

| Total Module Output Current | 8 A maximum per module |

| Output Isolation | 1500 V RMS channel-to-PLC backplane |

| Input-to-Output Isolation | 1500 V RMS |

| Response Time (Input to CPU) | < 10 ms |

| Response Time (CPU to Output) | < 10 ms |

| Power Requirements | 5 VDC, 160 mA (supplied by PLC backplane) |

| Diagnostic Features | LED Indicators per channel (ON/OFF status) |

| Operating Temperature Range | 0°C to +60°C (32°F to 140°F) |

| Storage Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Humidity Range | 5% to 95%, non-condensing |

| Dimensions | 100 x 50 x 110 mm |

| Weight | 0.2 kg |

| Mounting | Standard Series 90-30 PLC rack mounting |

| Environmental Protection | IP20 |

Applications

The GE IC693MAR590 I/O Module is used in a wide variety of industrial applications due to its flexibility and combination of inputs and outputs in a single module:

-

Packaging Machines: For reading sensors and controlling relays for packing and sealing machines.

-

Conveyor Systems: Monitoring limit switches and driving actuators to control conveyors.

-

HVAC Systems: Reading thermostats and controlling relays for heating, cooling, and ventilation equipment.

-

Water and Wastewater Treatment: For monitoring fluid levels and controlling pumps and valves.

-

Material Handling: Reading operator pushbuttons and light curtains, controlling relays and solenoids.

-

Building Automation: For lighting, access control, and alarm systems.

-

Food and Beverage Processing: For coordinating sensors and actuators in automated production lines.

Advantages

-

Compact Design: Combines inputs and outputs in one module, reducing rack space requirements.

-

Simplified Wiring: Fewer modules and reduced cabling complexity lead to faster installation and maintenance.

-

Flexible Voltage Support: Handles both AC and DC signals, making it adaptable to various field devices.

-

High Output Capacity: Each relay output can drive up to 2 A at AC or DC, suitable for heavy-duty loads.

-

Isolated Channels: Ensures safe operation with 1500 V isolation between I/O and PLC backplane.

-

Fast Response Time: Less than 10 ms latency for both inputs and outputs, suitable for real-time applications.

-

LED Diagnostics: Per-channel LED indicators provide at-a-glance status, aiding in troubleshooting.

-

Seamless PLC Integration: Designed specifically for the GE Series 90-30 PLC system.

-

Industrial Durability: Designed to operate reliably in harsh industrial environments.

-

Cost-Effective: Saves on hardware costs by combining I/O functionality into one module.

Frequently Asked Questions (FAQ)

-

What is the IC693MAR590 module used for?

It is a 16-point combination I/O module used for handling both digital input and relay output signals in GE Series 90-30 PLC systems.

-

How many inputs and outputs does it have?

The module provides 8 digital input channels and 8 relay output channels.

-

Does the module support AC and DC signals?

Yes, both inputs and outputs can handle AC or DC voltages.

-

What type of outputs does it provide?

It provides SPST-NO (Form A) relay outputs.

-

What is the maximum current per output?

Each relay output can drive up to 2 A.

-

Can this module be used in harsh environments?

Yes, it is designed for industrial environments with an operating temperature range of 0°C to +60°C and IP20 protection.

-

How is the module powered?

It is powered by 5 VDC from the Series 90-30 PLC backplane.

-

Is it compatible with other GE PLC systems?

It is specifically designed for the Series 90-30 PLC but may also be used in other GE systems with appropriate compatibility.

-

Does the module include diagnostic LEDs?

Yes, it has individual LEDs for each input and output channel for status monitoring.

-

What certifications does the module meet?

The IC693MAR590 complies with industrial safety and EMC standards as required for factory automation.

General Electric IC693MAR590 I/O Module

Manufacturer:GE

Product Number:IC693MAR590

Product Type:I/O Module

Origin:USA

Dimensions:100 x 50 x 110 mm

Weight:0.2 kg

Views:45

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IC693MAR590 I/O Module is a versatile 16-point combination module designed for use with the GE Fanuc Series 90-30 Programmable Logic Controller (PLC) systems. As a mixed I/O module, it offers both digital inputs and relay outputs within a single compact unit, providing a flexible and space-saving solution for industrial automation applications.

The IC693MAR590 is ideal for systems where there is a need to read input signals (such as switches, sensors, or pushbuttons) and control output devices (such as relays, solenoids, and indicator lamps) in one module. This combination helps reduce the number of modules needed in a rack, simplifies wiring, and lowers installation costs.

The module is engineered for reliable operation in demanding environments. It offers excellent isolation between input and output channels, noise immunity, and fast response times. Designed to seamlessly integrate into GE Series 90-30 PLCs, it supports a wide range of industrial applications, from simple machine control to complex process automation.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | IC693MAR590 |

| Product Type | 16-Point Combination I/O Module (8 In / 8 Out) |

| Input Channels | 8 Digital Inputs (AC/DC compatible) |

| Input Voltage Range | 0–30 VDC or 0–132 VAC |

| Input Current @ 120 VAC | 10 mA typical |

| Input Current @ 24 VDC | 7 mA typical |

| Output Channels | 8 Relay Outputs (Form A, SPST-NO) |

| Output Voltage Rating | 5–30 VDC or 5–250 VAC |

| Output Current Rating | 2 A max per point (resistive load) |

| Total Module Output Current | 8 A maximum per module |

| Output Isolation | 1500 V RMS channel-to-PLC backplane |

| Input-to-Output Isolation | 1500 V RMS |

| Response Time (Input to CPU) | < 10 ms |

| Response Time (CPU to Output) | < 10 ms |

| Power Requirements | 5 VDC, 160 mA (supplied by PLC backplane) |

| Diagnostic Features | LED Indicators per channel (ON/OFF status) |

| Operating Temperature Range | 0°C to +60°C (32°F to 140°F) |

| Storage Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Humidity Range | 5% to 95%, non-condensing |

| Dimensions | 100 x 50 x 110 mm |

| Weight | 0.2 kg |

| Mounting | Standard Series 90-30 PLC rack mounting |

| Environmental Protection | IP20 |

Applications

The GE IC693MAR590 I/O Module is used in a wide variety of industrial applications due to its flexibility and combination of inputs and outputs in a single module:

-

Packaging Machines: For reading sensors and controlling relays for packing and sealing machines.

-

Conveyor Systems: Monitoring limit switches and driving actuators to control conveyors.

-

HVAC Systems: Reading thermostats and controlling relays for heating, cooling, and ventilation equipment.

-

Water and Wastewater Treatment: For monitoring fluid levels and controlling pumps and valves.

-

Material Handling: Reading operator pushbuttons and light curtains, controlling relays and solenoids.

-

Building Automation: For lighting, access control, and alarm systems.

-

Food and Beverage Processing: For coordinating sensors and actuators in automated production lines.

Advantages

-

Compact Design: Combines inputs and outputs in one module, reducing rack space requirements.

-

Simplified Wiring: Fewer modules and reduced cabling complexity lead to faster installation and maintenance.

-

Flexible Voltage Support: Handles both AC and DC signals, making it adaptable to various field devices.

-

High Output Capacity: Each relay output can drive up to 2 A at AC or DC, suitable for heavy-duty loads.

-

Isolated Channels: Ensures safe operation with 1500 V isolation between I/O and PLC backplane.

-

Fast Response Time: Less than 10 ms latency for both inputs and outputs, suitable for real-time applications.

-

LED Diagnostics: Per-channel LED indicators provide at-a-glance status, aiding in troubleshooting.

-

Seamless PLC Integration: Designed specifically for the GE Series 90-30 PLC system.

-

Industrial Durability: Designed to operate reliably in harsh industrial environments.

-

Cost-Effective: Saves on hardware costs by combining I/O functionality into one module.

Frequently Asked Questions (FAQ)

-

What is the IC693MAR590 module used for?

It is a 16-point combination I/O module used for handling both digital input and relay output signals in GE Series 90-30 PLC systems.

-

How many inputs and outputs does it have?

The module provides 8 digital input channels and 8 relay output channels.

-

Does the module support AC and DC signals?

Yes, both inputs and outputs can handle AC or DC voltages.

-

What type of outputs does it provide?

It provides SPST-NO (Form A) relay outputs.

-

What is the maximum current per output?

Each relay output can drive up to 2 A.

-

Can this module be used in harsh environments?

Yes, it is designed for industrial environments with an operating temperature range of 0°C to +60°C and IP20 protection.

-

How is the module powered?

It is powered by 5 VDC from the Series 90-30 PLC backplane.

-

Is it compatible with other GE PLC systems?

It is specifically designed for the Series 90-30 PLC but may also be used in other GE systems with appropriate compatibility.

-

Does the module include diagnostic LEDs?

Yes, it has individual LEDs for each input and output channel for status monitoring.

-

What certifications does the module meet?

The IC693MAR590 complies with industrial safety and EMC standards as required for factory automation.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...