Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

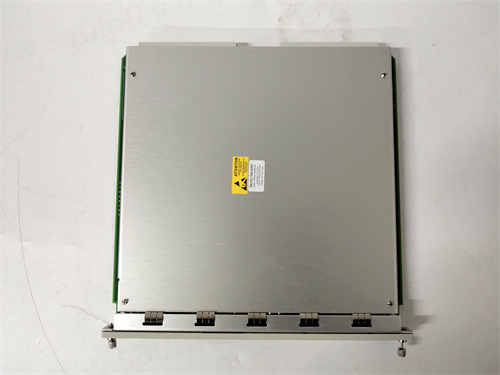

Bently Nevada 60M100-00 High Precision Vibration Module

Module Number:60M100-00

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

Bently Nevada 60M100-00 module, provided by Bently Nevada (now part of GE), is a powerful automation control module, particularly suitable for vibration monitoring and mechanical fault diagnosis of industrial equipment. The following is a detailed introduction to the module:

Main functions and applications

High precision vibration monitoring:

This module has high-precision vibration measurement capability and can monitor real-time parameters such as vibration velocity, acceleration, and displacement of the equipment.

By obtaining accurate vibration data, users can timely understand the health status of the equipment, predict possible failures, and take corresponding maintenance measures.

Real time fault diagnosis:

The 60M100-00 module has fault diagnosis function, which can identify and diagnose mechanical faults such as bearing wear, imbalance, looseness, etc. by collecting and analyzing vibration data.

This helps to detect potential faults early, avoid equipment damage and production interruptions, and improve equipment reliability and operational efficiency.

Powerful signal processing capability:

This module adopts advanced signal processing algorithms to filter, denoise, and extract features from the collected vibration signals, in order to improve signal quality and the accuracy of fault diagnosis.

At the same time, it also supports various signal conditioning functions such as filtering, amplification, and calibration to meet the needs of different devices and application scenarios.

Flexible configuration and integration:

The 60M100-00 module can be used as an independent status monitoring system or as part of machine integration, integrated with OEM control and instrumentation packages.

It supports multiple communication protocols and interfaces, facilitating data exchange and integration with other systems.

Provides rich configuration options that can be customized and configured according to specific application needs.

Application Fields

Bently Nevada 60M100-00 module is widely used in the following fields:

Wind turbine generator system: As part of state based maintenance, this module can identify turbine defects in advance, reduce crane costs, achieve early detection and minimize damage.

Turbines and other rotating equipment: Especially suitable for monitoring and protecting critical rotating equipment such as generators and compressors, ensuring the safe operation of the equipment.

Petrochemical and power industries: In these industries, this module is used for vibration monitoring and fault diagnosis of key industrial equipment, improving production efficiency and safety.

Technical features

High performance and flexibility: This module provides high-performance and flexible data collection capabilities, suitable for various testing, measurement, and control applications.

Advanced signal processing algorithms: Extract dozens of measurement values through complex signal processing algorithms, and customize the health index of each accelerometer point to specific bearing and gearbox characteristics.

Wide communication capability: Supports multiple communication protocols such as Modbus/TCP, facilitating data exchange and integration with other systems.

In summary, Bently Nevada 60M100-00 module is a powerful, high-precision, and reliable vibration monitoring and fault diagnosis solution, providing important technical support and guarantee for the maintenance and management of industrial equipment.

Bently Nevada 60M100-00 High Precision Vibration Module

Module Number:60M100-00

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

Bently Nevada 60M100-00 module, provided by Bently Nevada (now part of GE), is a powerful automation control module, particularly suitable for vibration monitoring and mechanical fault diagnosis of industrial equipment. The following is a detailed introduction to the module:

Main functions and applications

High precision vibration monitoring:

This module has high-precision vibration measurement capability and can monitor real-time parameters such as vibration velocity, acceleration, and displacement of the equipment.

By obtaining accurate vibration data, users can timely understand the health status of the equipment, predict possible failures, and take corresponding maintenance measures.

Real time fault diagnosis:

The 60M100-00 module has fault diagnosis function, which can identify and diagnose mechanical faults such as bearing wear, imbalance, looseness, etc. by collecting and analyzing vibration data.

This helps to detect potential faults early, avoid equipment damage and production interruptions, and improve equipment reliability and operational efficiency.

Powerful signal processing capability:

This module adopts advanced signal processing algorithms to filter, denoise, and extract features from the collected vibration signals, in order to improve signal quality and the accuracy of fault diagnosis.

At the same time, it also supports various signal conditioning functions such as filtering, amplification, and calibration to meet the needs of different devices and application scenarios.

Flexible configuration and integration:

The 60M100-00 module can be used as an independent status monitoring system or as part of machine integration, integrated with OEM control and instrumentation packages.

It supports multiple communication protocols and interfaces, facilitating data exchange and integration with other systems.

Provides rich configuration options that can be customized and configured according to specific application needs.

Application Fields

Bently Nevada 60M100-00 module is widely used in the following fields:

Wind turbine generator system: As part of state based maintenance, this module can identify turbine defects in advance, reduce crane costs, achieve early detection and minimize damage.

Turbines and other rotating equipment: Especially suitable for monitoring and protecting critical rotating equipment such as generators and compressors, ensuring the safe operation of the equipment.

Petrochemical and power industries: In these industries, this module is used for vibration monitoring and fault diagnosis of key industrial equipment, improving production efficiency and safety.

Technical features

High performance and flexibility: This module provides high-performance and flexible data collection capabilities, suitable for various testing, measurement, and control applications.

Advanced signal processing algorithms: Extract dozens of measurement values through complex signal processing algorithms, and customize the health index of each accelerometer point to specific bearing and gearbox characteristics.

Wide communication capability: Supports multiple communication protocols such as Modbus/TCP, facilitating data exchange and integration with other systems.

In summary, Bently Nevada 60M100-00 module is a powerful, high-precision, and reliable vibration monitoring and fault diagnosis solution, providing important technical support and guarantee for the maintenance and management of industrial equipment.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...