Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

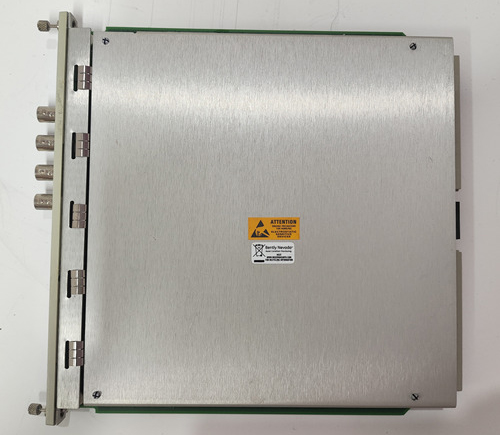

Bently Nevada 9200-01-01-02-00 Dual-line velocity seismic sensor

Manufacturer:Bently Nevada

Product Number:9200-01-01-02-00

Product Type:Dual-line velocity seismic sensor

Origin:USA

Sensor diameter:41.4mm

Weight :3 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 9200-01-01-02-00 is a high-performance dual-line velocity seismic sensor designed for precise vibration monitoring in industrial and rotating machinery applications. Built to withstand harsh operating environments, this sensor delivers reliable and accurate measurements for critical condition monitoring and predictive maintenance programs.

Its rugged stainless-steel housing, wide dynamic range, and stable output make it ideal for machinery such as turbines, compressors, pumps, and motors, where continuous vibration surveillance is vital for operational safety and equipment longevity. The unit is fully compatible with Bently Nevada monitoring systems and can be seamlessly integrated into existing vibration monitoring infrastructures.

Product Advantages

-

High Measurement Accuracy – Provides precise velocity readings, enabling early fault detection and reducing the risk of unexpected downtime.

-

Rugged Industrial Design – Engineered to withstand severe mechanical stress, temperature extremes, and corrosive environments.

-

Wide Frequency Response – Captures a broad range of vibration frequencies, ensuring comprehensive monitoring of machinery conditions.

-

Stable Long-Term Output – Delivers consistent performance over time, minimizing the need for frequent recalibration.

-

Seamless System Integration – Fully compatible with Bently Nevada monitoring equipment for easy installation and reliable data communication.

-

Low Maintenance Requirements – Designed for durability, reducing operational interruptions and long-term maintenance costs.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 9200-01-01-02-00 |

| Sensor Type | Dual-line velocity seismic sensor |

| Output Signal | Velocity (mm/s or in/s) |

| Frequency Range | 4.5 Hz to 2,000 Hz |

| Sensitivity | 3.94 mV/mm/s (±5%) |

| Operating Temperature Range | -40°C to +100°C (-40°F to +212°F) |

| Housing Material | Stainless Steel |

| Mounting Method | Stud mount |

| Power Requirements | 18–30 VDC |

| Sensor diameter | 41.4mm |

| Weight | 3 kg |

| Environmental Protection | IP65 |

| Cable Connection | Two-wire system |

| Shock Limit | 5,000 g peak |

Product Applications

-

Turbomachinery Monitoring – Ideal for turbines, compressors, and gearboxes in power plants and petrochemical industries.

-

Pumps and Motors – Detects early-stage faults in pumps, electric motors, and fans to prevent costly failures.

-

Industrial Manufacturing – Suitable for monitoring high-speed production equipment where vibration anomalies can lead to quality issues.

-

Oil & Gas Operations – Used for critical rotating equipment in offshore and onshore platforms.

-

Predictive Maintenance Programs – Integrates with predictive analytics systems for condition-based maintenance.

-

Steel and Paper Mills – Monitors heavy-duty rollers, bearings, and drive systems for abnormal vibration patterns.

Installation Guidelines

-

Site Preparation – Ensure the mounting surface is clean, flat, and free of contaminants to guarantee proper sensor coupling.

-

Mounting Method – Use the specified stud mount for secure installation; torque according to manufacturer recommendations.

-

Orientation – Align the sensor for optimal vibration sensitivity along the desired measurement axis.

-

Electrical Connection – Connect using shielded two-wire cable, ensuring correct polarity and grounding to prevent noise interference.

-

Calibration Check – Verify sensor output using a vibration calibrator before commissioning.

-

Environmental Protection – Ensure cable entry points are sealed for IP65 compliance in harsh environments.

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the Bently Nevada 9200-01-01-02-00?

A1: It measures machinery vibration velocity to detect faults, imbalances, or wear in rotating equipment.

Q2: Can it be used in explosive environments?

A2: Only if installed with proper certified protective housings and accessories approved for hazardous areas.

Q3: How is the sensor powered?

A3: It operates on an 18–30 VDC supply through a two-wire connection.

Q4: Is calibration required after installation?

A4: A one-time calibration check is recommended before commissioning, but frequent recalibration is generally not needed.

Q5: What is the difference between velocity and acceleration sensors?

A5: Velocity sensors like this one are better for general machine condition monitoring, while accelerometers are used for high-frequency fault detection.

Q6: Can the sensor be mounted on any axis?

A6: Yes, but the sensitivity and frequency response should match the monitoring requirements.

Q7: What maintenance does it require?

A7: Periodic visual inspection of mounting integrity and cable condition is sufficient.

Q8: Is it waterproof?

A8: Yes, with IP65 protection, it is resistant to dust and water spray.

Q9: What monitoring systems is it compatible with?

A9: It is fully compatible with Bently Nevada vibration monitoring and protection systems.

Q10: Can it measure displacement as well?

A10: No, it measures velocity directly; displacement can be derived through integration in the monitoring system.

Bently Nevada 9200-01-01-02-00 Dual-line velocity seismic sensor

Manufacturer:Bently Nevada

Product Number:9200-01-01-02-00

Product Type:Dual-line velocity seismic sensor

Origin:USA

Sensor diameter:41.4mm

Weight :3 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 9200-01-01-02-00 is a high-performance dual-line velocity seismic sensor designed for precise vibration monitoring in industrial and rotating machinery applications. Built to withstand harsh operating environments, this sensor delivers reliable and accurate measurements for critical condition monitoring and predictive maintenance programs.

Its rugged stainless-steel housing, wide dynamic range, and stable output make it ideal for machinery such as turbines, compressors, pumps, and motors, where continuous vibration surveillance is vital for operational safety and equipment longevity. The unit is fully compatible with Bently Nevada monitoring systems and can be seamlessly integrated into existing vibration monitoring infrastructures.

Product Advantages

-

High Measurement Accuracy – Provides precise velocity readings, enabling early fault detection and reducing the risk of unexpected downtime.

-

Rugged Industrial Design – Engineered to withstand severe mechanical stress, temperature extremes, and corrosive environments.

-

Wide Frequency Response – Captures a broad range of vibration frequencies, ensuring comprehensive monitoring of machinery conditions.

-

Stable Long-Term Output – Delivers consistent performance over time, minimizing the need for frequent recalibration.

-

Seamless System Integration – Fully compatible with Bently Nevada monitoring equipment for easy installation and reliable data communication.

-

Low Maintenance Requirements – Designed for durability, reducing operational interruptions and long-term maintenance costs.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 9200-01-01-02-00 |

| Sensor Type | Dual-line velocity seismic sensor |

| Output Signal | Velocity (mm/s or in/s) |

| Frequency Range | 4.5 Hz to 2,000 Hz |

| Sensitivity | 3.94 mV/mm/s (±5%) |

| Operating Temperature Range | -40°C to +100°C (-40°F to +212°F) |

| Housing Material | Stainless Steel |

| Mounting Method | Stud mount |

| Power Requirements | 18–30 VDC |

| Sensor diameter | 41.4mm |

| Weight | 3 kg |

| Environmental Protection | IP65 |

| Cable Connection | Two-wire system |

| Shock Limit | 5,000 g peak |

Product Applications

-

Turbomachinery Monitoring – Ideal for turbines, compressors, and gearboxes in power plants and petrochemical industries.

-

Pumps and Motors – Detects early-stage faults in pumps, electric motors, and fans to prevent costly failures.

-

Industrial Manufacturing – Suitable for monitoring high-speed production equipment where vibration anomalies can lead to quality issues.

-

Oil & Gas Operations – Used for critical rotating equipment in offshore and onshore platforms.

-

Predictive Maintenance Programs – Integrates with predictive analytics systems for condition-based maintenance.

-

Steel and Paper Mills – Monitors heavy-duty rollers, bearings, and drive systems for abnormal vibration patterns.

Installation Guidelines

-

Site Preparation – Ensure the mounting surface is clean, flat, and free of contaminants to guarantee proper sensor coupling.

-

Mounting Method – Use the specified stud mount for secure installation; torque according to manufacturer recommendations.

-

Orientation – Align the sensor for optimal vibration sensitivity along the desired measurement axis.

-

Electrical Connection – Connect using shielded two-wire cable, ensuring correct polarity and grounding to prevent noise interference.

-

Calibration Check – Verify sensor output using a vibration calibrator before commissioning.

-

Environmental Protection – Ensure cable entry points are sealed for IP65 compliance in harsh environments.

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the Bently Nevada 9200-01-01-02-00?

A1: It measures machinery vibration velocity to detect faults, imbalances, or wear in rotating equipment.

Q2: Can it be used in explosive environments?

A2: Only if installed with proper certified protective housings and accessories approved for hazardous areas.

Q3: How is the sensor powered?

A3: It operates on an 18–30 VDC supply through a two-wire connection.

Q4: Is calibration required after installation?

A4: A one-time calibration check is recommended before commissioning, but frequent recalibration is generally not needed.

Q5: What is the difference between velocity and acceleration sensors?

A5: Velocity sensors like this one are better for general machine condition monitoring, while accelerometers are used for high-frequency fault detection.

Q6: Can the sensor be mounted on any axis?

A6: Yes, but the sensitivity and frequency response should match the monitoring requirements.

Q7: What maintenance does it require?

A7: Periodic visual inspection of mounting integrity and cable condition is sufficient.

Q8: Is it waterproof?

A8: Yes, with IP65 protection, it is resistant to dust and water spray.

Q9: What monitoring systems is it compatible with?

A9: It is fully compatible with Bently Nevada vibration monitoring and protection systems.

Q10: Can it measure displacement as well?

A10: No, it measures velocity directly; displacement can be derived through integration in the monitoring system.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...