Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

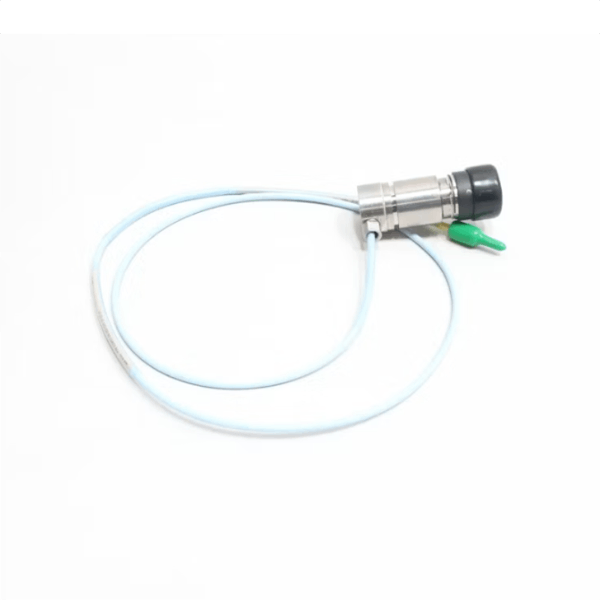

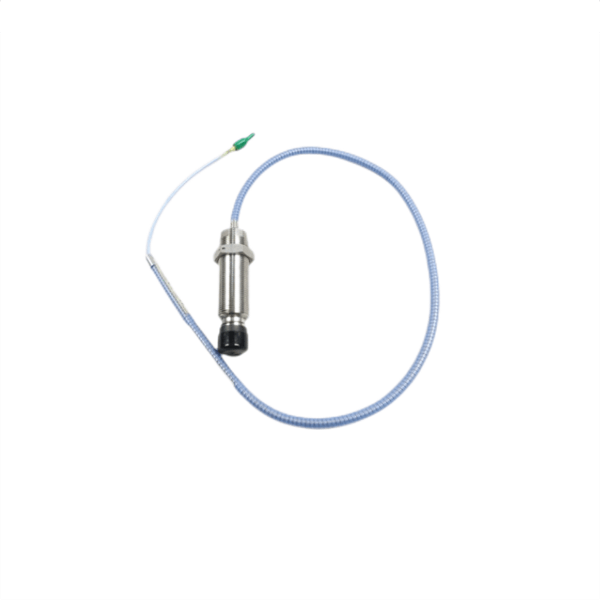

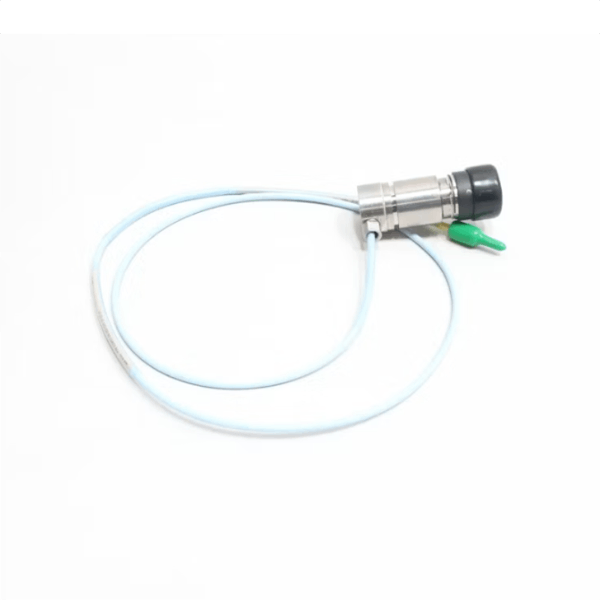

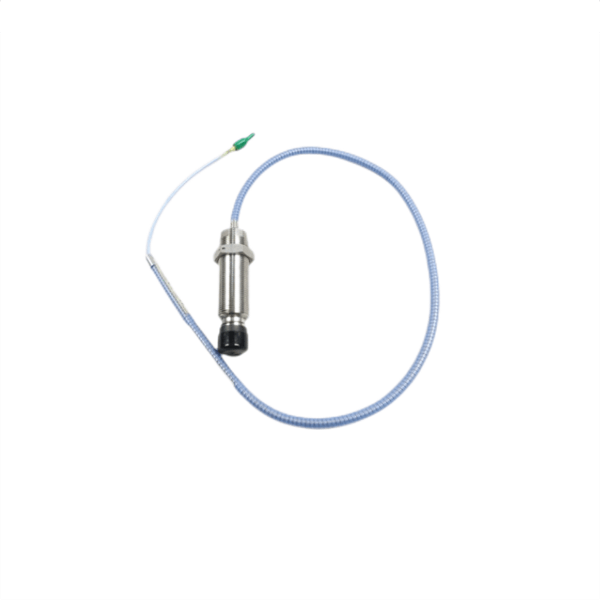

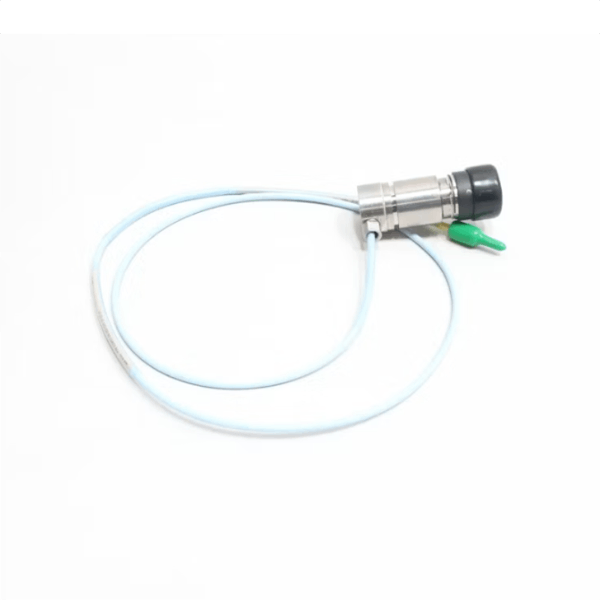

Bently Nevada 330851-02-000-060-10-00-05 3300 XL 25 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330851-02-000-060-10-00-05

Product Type:3300 XL 25 mm Proximity Probe

Origin:USA

Total Length:1m

Weight :0.23 kg

Views:21

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330851-02-000-060-10-00-05 3300 XL 25 mm Proximity Probe is a precision instrument designed for monitoring vibration and shaft position in rotating machinery. Part of the 3300 XL series, this probe provides highly reliable measurements even in harsh industrial environments. It operates on eddy current displacement technology, allowing accurate detection of shaft movement without physical contact. This model is suitable for turbines, compressors, pumps, and other critical rotating equipment in power generation, oil & gas, and industrial process applications.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330851-02-000-060-10-00-05 |

| Series | 3300 XL |

| Probe Type | 25 mm Proximity Probe |

| Measurement Principle | Eddy Current Displacement |

| Output | AC/DC Voltage |

| Operating Temperature | -40°C to 120°C |

| Total Length | 1 m |

| Weight | 0.23 kg |

| Cable Type | Shielded coaxial |

| Connector Type | Standard Bently 3300 XL connector |

| Target Material Compatibility | Ferrous metals |

| Maximum Vibration Tolerance | 50 g |

| Signal Frequency Response | DC to 20 kHz |

Product Applications

-

Rotating Machinery Monitoring: Turbines, generators, compressors, pumps, and motors.

-

Industrial Plants: Oil & gas, petrochemical, and chemical processing plants.

-

Power Generation: Steam, gas, and hydroelectric power plants for vibration and shaft position monitoring.

-

Condition-Based Maintenance: Early detection of misalignment, imbalance, or wear in rotating equipment.

-

Critical Asset Protection: Integration with 3300 XL monitoring systems for machinery protection.

Product Advantages

-

High Accuracy: Eddy current technology provides precise shaft position measurements with minimal drift.

-

Robust Design: Resistant to high temperatures, vibrations, and industrial contaminants.

-

Non-Contact Measurement: Reduces wear and maintenance needs while enabling continuous monitoring.

-

Compatibility: Fully compatible with Bently Nevada 3300 XL monitoring systems.

-

Fast Response: Capable of capturing high-frequency vibration events for critical machinery analysis.

-

Long Cable Length: 1-meter total length allows flexible installation options.

FAQ

-

What is the frequency response of this probe?

The probe supports a frequency range from DC up to 20 kHz, suitable for high-speed machinery monitoring.

-

Is this probe compatible with all 3300 XL modules?

Yes, it is fully compatible with 3300 XL monitoring system modules and rack assemblies.

-

Can this probe measure non-ferrous shafts?

No, the eddy current principle requires ferrous target material for accurate displacement readings.

-

What type of signal does the probe output?

The probe provides an AC or DC voltage signal compatible with Bently Nevada 3300 XL input modules.

-

How is the probe grounded?

It uses the shielded coaxial cable to connect to the 3300 XL system’s grounded input, minimizing electrical noise.

-

Can the probe operate in high-temperature environments?

Yes, it operates safely in temperatures ranging from -40°C to 120°C.

-

What is the maximum vibration the probe can tolerate?

The probe can withstand vibrations up to 50 g without affecting measurement accuracy.

-

Is remote calibration required for this probe?

No, the probe is factory-calibrated; however, system calibration may be required during installation.

-

What is the recommended target-to-probe gap?

The recommended initial gap is typically 0.25 mm to 0.75 mm, adjustable depending on the application.

-

Does the probe include anti-rotation features?

Yes, the design includes features to maintain orientation and prevent probe rotation in high-vibration environments.

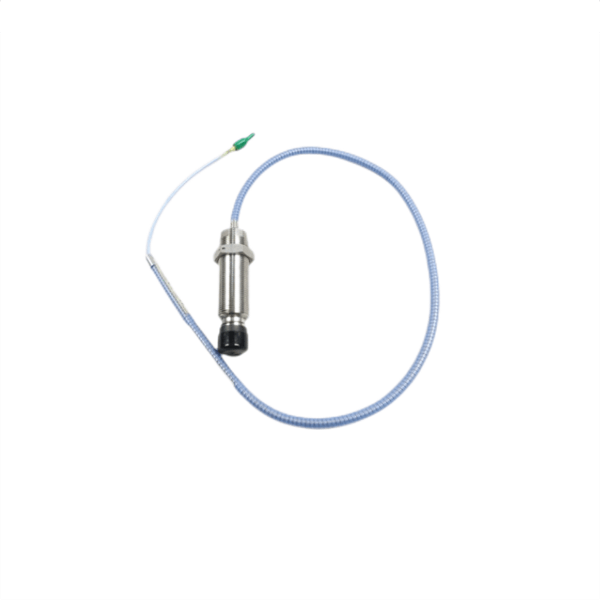

Bently Nevada 330851-02-000-060-10-00-05 3300 XL 25 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330851-02-000-060-10-00-05

Product Type:3300 XL 25 mm Proximity Probe

Origin:USA

Total Length:1m

Weight :0.23 kg

Views:21

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330851-02-000-060-10-00-05 3300 XL 25 mm Proximity Probe is a precision instrument designed for monitoring vibration and shaft position in rotating machinery. Part of the 3300 XL series, this probe provides highly reliable measurements even in harsh industrial environments. It operates on eddy current displacement technology, allowing accurate detection of shaft movement without physical contact. This model is suitable for turbines, compressors, pumps, and other critical rotating equipment in power generation, oil & gas, and industrial process applications.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330851-02-000-060-10-00-05 |

| Series | 3300 XL |

| Probe Type | 25 mm Proximity Probe |

| Measurement Principle | Eddy Current Displacement |

| Output | AC/DC Voltage |

| Operating Temperature | -40°C to 120°C |

| Total Length | 1 m |

| Weight | 0.23 kg |

| Cable Type | Shielded coaxial |

| Connector Type | Standard Bently 3300 XL connector |

| Target Material Compatibility | Ferrous metals |

| Maximum Vibration Tolerance | 50 g |

| Signal Frequency Response | DC to 20 kHz |

Product Applications

-

Rotating Machinery Monitoring: Turbines, generators, compressors, pumps, and motors.

-

Industrial Plants: Oil & gas, petrochemical, and chemical processing plants.

-

Power Generation: Steam, gas, and hydroelectric power plants for vibration and shaft position monitoring.

-

Condition-Based Maintenance: Early detection of misalignment, imbalance, or wear in rotating equipment.

-

Critical Asset Protection: Integration with 3300 XL monitoring systems for machinery protection.

Product Advantages

-

High Accuracy: Eddy current technology provides precise shaft position measurements with minimal drift.

-

Robust Design: Resistant to high temperatures, vibrations, and industrial contaminants.

-

Non-Contact Measurement: Reduces wear and maintenance needs while enabling continuous monitoring.

-

Compatibility: Fully compatible with Bently Nevada 3300 XL monitoring systems.

-

Fast Response: Capable of capturing high-frequency vibration events for critical machinery analysis.

-

Long Cable Length: 1-meter total length allows flexible installation options.

FAQ

-

What is the frequency response of this probe?

The probe supports a frequency range from DC up to 20 kHz, suitable for high-speed machinery monitoring.

-

Is this probe compatible with all 3300 XL modules?

Yes, it is fully compatible with 3300 XL monitoring system modules and rack assemblies.

-

Can this probe measure non-ferrous shafts?

No, the eddy current principle requires ferrous target material for accurate displacement readings.

-

What type of signal does the probe output?

The probe provides an AC or DC voltage signal compatible with Bently Nevada 3300 XL input modules.

-

How is the probe grounded?

It uses the shielded coaxial cable to connect to the 3300 XL system’s grounded input, minimizing electrical noise.

-

Can the probe operate in high-temperature environments?

Yes, it operates safely in temperatures ranging from -40°C to 120°C.

-

What is the maximum vibration the probe can tolerate?

The probe can withstand vibrations up to 50 g without affecting measurement accuracy.

-

Is remote calibration required for this probe?

No, the probe is factory-calibrated; however, system calibration may be required during installation.

-

What is the recommended target-to-probe gap?

The recommended initial gap is typically 0.25 mm to 0.75 mm, adjustable depending on the application.

-

Does the probe include anti-rotation features?

Yes, the design includes features to maintain orientation and prevent probe rotation in high-vibration environments.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...