Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

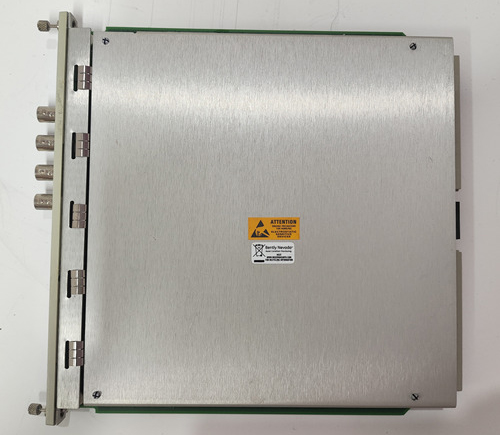

Bently Nevada 330103-00-06-10-02-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-00-06-10-02-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1 m

Weight:0.323 kg

Views:60

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-06-10-02-05 Proximity Probe is part of the renowned 3300 XL 8 mm series, a benchmark in industrial non-contact vibration and position sensing. Specifically designed for critical machinery monitoring, this probe provides accurate shaft displacement data in high-speed rotating equipment, making it essential in environments like oil refineries, power plants, and petrochemical facilities.

This particular model—330103-00-06-10-02-05—features a length, 1 meter cable, standard connector, and reverse polarity configuration, which is essential for certain proximity measurement systems. Built to work in harsh conditions, it pairs with matching Proximitor® sensors and extension cables to form a high-precision measurement system.

Product Specifications

| Specification | Details |

|---|---|

| Model Number | 330103-00-06-10-02-05 |

| Series | Bently Nevada 3300 XL 8 mm |

| Probe Tip Diameter | 8 mm (0.315 in) |

| Thread Type | 3/8-24 UNF-2A |

| Probe Length | 6.0 inches (152 mm) |

| Cable Length | 1 meter |

| Connector Type | Miniature coaxial, reverse polarity |

| System Type | Eddy Current Proximity Probe System |

| Measurement Range | Up to 2 mm (80 mils) |

| Linear Range | 0.5 mm to 2.0 mm (20 to 80 mils) |

| Operating Temperature | -35°C to +175°C (-31°F to +347°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +351°F) |

| Frequency Response | 0 to 10 kHz |

| Mounting Style | Threaded, stainless steel body |

| Environmental Rating | Hermetically sealed, corrosion-resistant |

| Material | Stainless Steel 303 |

| Weight (with cable) | 0.323 kg |

Product Applications

The 330103-00-06-10-02-05 proximity probe is an indispensable component in a wide array of industrial condition monitoring systems. It plays a pivotal role in:

-

Steam and Gas Turbines – Measuring rotor shaft position and vibration with high accuracy.

-

Centrifugal and Reciprocating Compressors – Preventing bearing wear and rotor-to-stator contact through early fault detection.

-

Industrial Pumps – Monitoring pump shaft position to prevent dry-run conditions or cavitation.

-

Electric Motors and Generators – Identifying misalignment and bearing faults before failure occurs.

-

Gear Trains – Detecting axial movement or shaft eccentricity in gearboxes.

-

Oil & Gas and Petrochemical Sectors – Designed to function in explosive atmospheres, critical for machinery safety.

Product Advantages

-

Highly Precise Shaft Monitoring

Delivers sub-mil accuracy for vibration and position measurements—ideal for API 670-compliant monitoring systems.

-

Reverse Polarity Support

The 02 polarity type allows compatibility with alternate sensor configurations and diagnostics systems.

-

Robust Construction for Harsh Environments

Hermetically sealed and corrosion-resistant housing ensures long life in aggressive plant atmospheres.

-

Extended Operating Temperature Range

Functions reliably in extreme temperatures from -35°C to +175°C, suitable for hot machinery housing or enclosed environments.

-

Compatibility and Modularity

Works seamlessly with 3300 XL Proximitor® sensors and extension cables for a complete measurement chain.

-

Long-Term Stability and Reliability

Known for excellent linearity and minimal drift, reducing the frequency of recalibration.

-

Compact and Simple Mounting

3/8-24 UNF thread allows easy integration into standard mounting brackets and housings.

-

Industry-Proven Design

Trusted by OEMs and plant operators worldwide for decades in high-value assets.

-

Non-Contact Operation

Reduces wear and maintenance needs compared to mechanical or contact-based sensors.

-

Global Support and Documentation

Backed by GE/Baker Hughes with comprehensive global technical and field service networks.

Frequently Asked Questions (FAQ)

-

What is the key difference between 330103-00-06-10-02-05 and 330103-00-06-10-01-00?

The main difference is the connector polarity. 02 denotes reverse polarity, which is required in some systems.

-

What systems is this probe compatible with?

It works with Bently Nevada 3300 XL Proximitor® sensors and related monitoring systems.

-

Can this proximity probe operate in high-temperature zones?

Yes, it is rated up to +175°C during operation.

-

What is the maximum measurable shaft movement?

It can measure up to 2 mm of shaft displacement.

-

Is this probe suitable for API 670 compliance?

Absolutely. The 3300 XL series is fully compliant with API 670 specifications.

-

Can the cable be disconnected or replaced?

The cable is permanently attached to the probe body. Cable extensions are made via connectors.

-

What type of thread is used for mounting?

A standard 3/8-24 UNF-2A threaded shaft allows universal mounting.

-

Is it intrinsically safe for hazardous areas?

Yes, when used with appropriate IS barriers and certified components.

-

How often does the probe need recalibration?

Factory calibration is stable over years. Check according to your plant’s predictive maintenance policy.

-

What is the lead time for replacement units?

This depends on supplier stock, but standard configurations like this typically have short lead times.

Bently Nevada 330103-00-06-10-02-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-00-06-10-02-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1 m

Weight:0.323 kg

Views:60

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-06-10-02-05 Proximity Probe is part of the renowned 3300 XL 8 mm series, a benchmark in industrial non-contact vibration and position sensing. Specifically designed for critical machinery monitoring, this probe provides accurate shaft displacement data in high-speed rotating equipment, making it essential in environments like oil refineries, power plants, and petrochemical facilities.

This particular model—330103-00-06-10-02-05—features a length, 1 meter cable, standard connector, and reverse polarity configuration, which is essential for certain proximity measurement systems. Built to work in harsh conditions, it pairs with matching Proximitor® sensors and extension cables to form a high-precision measurement system.

Product Specifications

| Specification | Details |

|---|---|

| Model Number | 330103-00-06-10-02-05 |

| Series | Bently Nevada 3300 XL 8 mm |

| Probe Tip Diameter | 8 mm (0.315 in) |

| Thread Type | 3/8-24 UNF-2A |

| Probe Length | 6.0 inches (152 mm) |

| Cable Length | 1 meter |

| Connector Type | Miniature coaxial, reverse polarity |

| System Type | Eddy Current Proximity Probe System |

| Measurement Range | Up to 2 mm (80 mils) |

| Linear Range | 0.5 mm to 2.0 mm (20 to 80 mils) |

| Operating Temperature | -35°C to +175°C (-31°F to +347°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +351°F) |

| Frequency Response | 0 to 10 kHz |

| Mounting Style | Threaded, stainless steel body |

| Environmental Rating | Hermetically sealed, corrosion-resistant |

| Material | Stainless Steel 303 |

| Weight (with cable) | 0.323 kg |

Product Applications

The 330103-00-06-10-02-05 proximity probe is an indispensable component in a wide array of industrial condition monitoring systems. It plays a pivotal role in:

-

Steam and Gas Turbines – Measuring rotor shaft position and vibration with high accuracy.

-

Centrifugal and Reciprocating Compressors – Preventing bearing wear and rotor-to-stator contact through early fault detection.

-

Industrial Pumps – Monitoring pump shaft position to prevent dry-run conditions or cavitation.

-

Electric Motors and Generators – Identifying misalignment and bearing faults before failure occurs.

-

Gear Trains – Detecting axial movement or shaft eccentricity in gearboxes.

-

Oil & Gas and Petrochemical Sectors – Designed to function in explosive atmospheres, critical for machinery safety.

Product Advantages

-

Highly Precise Shaft Monitoring

Delivers sub-mil accuracy for vibration and position measurements—ideal for API 670-compliant monitoring systems.

-

Reverse Polarity Support

The 02 polarity type allows compatibility with alternate sensor configurations and diagnostics systems.

-

Robust Construction for Harsh Environments

Hermetically sealed and corrosion-resistant housing ensures long life in aggressive plant atmospheres.

-

Extended Operating Temperature Range

Functions reliably in extreme temperatures from -35°C to +175°C, suitable for hot machinery housing or enclosed environments.

-

Compatibility and Modularity

Works seamlessly with 3300 XL Proximitor® sensors and extension cables for a complete measurement chain.

-

Long-Term Stability and Reliability

Known for excellent linearity and minimal drift, reducing the frequency of recalibration.

-

Compact and Simple Mounting

3/8-24 UNF thread allows easy integration into standard mounting brackets and housings.

-

Industry-Proven Design

Trusted by OEMs and plant operators worldwide for decades in high-value assets.

-

Non-Contact Operation

Reduces wear and maintenance needs compared to mechanical or contact-based sensors.

-

Global Support and Documentation

Backed by GE/Baker Hughes with comprehensive global technical and field service networks.

Frequently Asked Questions (FAQ)

-

What is the key difference between 330103-00-06-10-02-05 and 330103-00-06-10-01-00?

The main difference is the connector polarity. 02 denotes reverse polarity, which is required in some systems.

-

What systems is this probe compatible with?

It works with Bently Nevada 3300 XL Proximitor® sensors and related monitoring systems.

-

Can this proximity probe operate in high-temperature zones?

Yes, it is rated up to +175°C during operation.

-

What is the maximum measurable shaft movement?

It can measure up to 2 mm of shaft displacement.

-

Is this probe suitable for API 670 compliance?

Absolutely. The 3300 XL series is fully compliant with API 670 specifications.

-

Can the cable be disconnected or replaced?

The cable is permanently attached to the probe body. Cable extensions are made via connectors.

-

What type of thread is used for mounting?

A standard 3/8-24 UNF-2A threaded shaft allows universal mounting.

-

Is it intrinsically safe for hazardous areas?

Yes, when used with appropriate IS barriers and certified components.

-

How often does the probe need recalibration?

Factory calibration is stable over years. Check according to your plant’s predictive maintenance policy.

-

What is the lead time for replacement units?

This depends on supplier stock, but standard configurations like this typically have short lead times.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...