Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

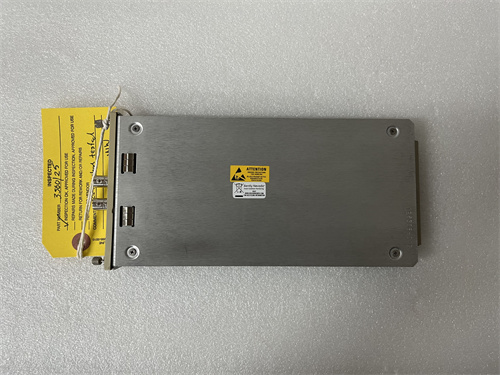

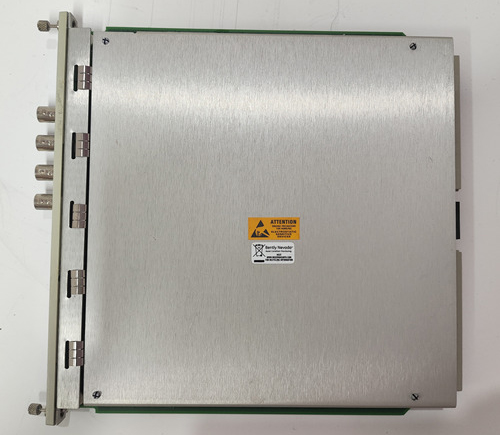

Bently Nevada 3300/16-12-01-00-00 Dual Vibration Monitor

Brand:Bently Nevada

Model Number:3300/16-12-01-00-00

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:5.7 cm x 20.3 cm x 33.0 cm

Weight:1.5 kg

Price:USD59

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 3300/16-12-01-00-00 is designed for continuous monitoring and measurement of rotating machinery. This dual vibration monitor tracks two independent channels of radial vibration and the average shaft position (gap).

Key Features and Specifications

- Dual Vibration Monitoring: Measures two channels of vibration simultaneously, offering a complete view of machine health.

- Shaft Position Monitoring: Accurately determines the average shaft position (gap) using proximity probes.

- Proximity Probe Compatibility: Integrates seamlessly with various proximity probe and Proximitor® systems.

- Robust Construction: Built to endure harsh industrial environments and ensure reliable operation.

- Advanced Signal Processing: Utilizes sophisticated algorithms for precise vibration and gap analysis.

- Customizable Configuration: Provides flexibility to tailor the configuration for specific application needs.

- Integration Capabilities: Can be incorporated into larger condition monitoring systems for improved data management and analysis.

Typical Applications

- Turbomachinery: Monitors vibration and shaft position in turbines, compressors, and pumps.

- Motors: Detects imbalances, misalignment, and other mechanical issues in electric motors.

- Generators: Assesses vibration levels and shaft dynamics in generators.

- Industrial Machinery: Monitors critical rotating equipment across various industries.

Benefits

- Early Fault Detection: Identifies potential problems before they lead to costly failures.

- Increased Reliability: Enhances the reliability and availability of rotating equipment.

- Reduced Maintenance Costs: Optimizes maintenance schedules and reduces downtime.

- Enhanced Safety: Improves safety by detecting abnormal conditions early.

Bently Nevada 3300/16-12-01-00-00 Dual Vibration Monitor

Brand:Bently Nevada

Model Number:3300/16-12-01-00-00

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:5.7 cm x 20.3 cm x 33.0 cm

Weight:1.5 kg

Price:USD59

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 3300/16-12-01-00-00 is designed for continuous monitoring and measurement of rotating machinery. This dual vibration monitor tracks two independent channels of radial vibration and the average shaft position (gap).

Key Features and Specifications

- Dual Vibration Monitoring: Measures two channels of vibration simultaneously, offering a complete view of machine health.

- Shaft Position Monitoring: Accurately determines the average shaft position (gap) using proximity probes.

- Proximity Probe Compatibility: Integrates seamlessly with various proximity probe and Proximitor® systems.

- Robust Construction: Built to endure harsh industrial environments and ensure reliable operation.

- Advanced Signal Processing: Utilizes sophisticated algorithms for precise vibration and gap analysis.

- Customizable Configuration: Provides flexibility to tailor the configuration for specific application needs.

- Integration Capabilities: Can be incorporated into larger condition monitoring systems for improved data management and analysis.

Typical Applications

- Turbomachinery: Monitors vibration and shaft position in turbines, compressors, and pumps.

- Motors: Detects imbalances, misalignment, and other mechanical issues in electric motors.

- Generators: Assesses vibration levels and shaft dynamics in generators.

- Industrial Machinery: Monitors critical rotating equipment across various industries.

Benefits

- Early Fault Detection: Identifies potential problems before they lead to costly failures.

- Increased Reliability: Enhances the reliability and availability of rotating equipment.

- Reduced Maintenance Costs: Optimizes maintenance schedules and reduces downtime.

- Enhanced Safety: Improves safety by detecting abnormal conditions early.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...