Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

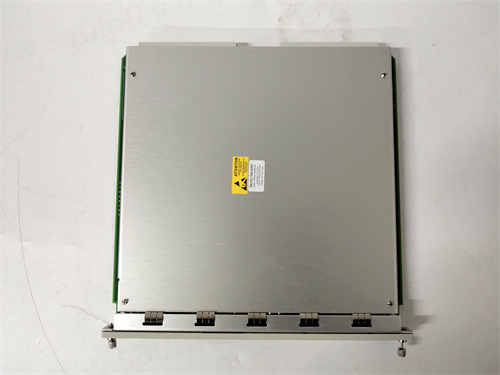

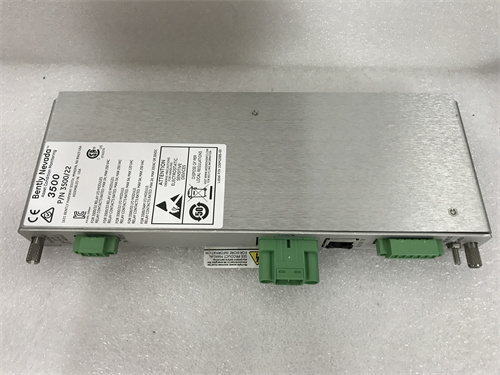

Bently Nevada 330881-28-00-164-07-02 PROXPAC XL Proximity Sensors

Manufacturer:Bently Nevada

Product Number:330881-28-00-164-07-02

Product Type:PROXPAC XL Proximity Sensors

Origin:USA

Dimensions:91.4 x 144.8 mm

Weight :1.44 kg

Views:3

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330881-28-00-164-07-02 PROXPAC XL Proximity Sensor is a high-performance sensor designed for precision monitoring of rotating machinery. It provides reliable vibration and position measurement in demanding industrial environments. The PROXPAC XL series is widely used in critical machinery applications, offering accurate shaft displacement readings and early detection of mechanical issues. This sensor supports robust data acquisition and is engineered to meet the stringent requirements of process and power generation industries.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330881-28-00-164-07-02 |

| Sensor Type | Proximity / Eddy-Current |

| Measurement Range | ±25.4 mm (typical, depending on probe type) |

| Frequency Response | DC to 25 kHz |

| Output Signal | Differential Voltage or 4-20 mA (depending on configuration) |

| Operating Temperature | -40°C to 120°C |

| Housing Material | Stainless Steel / Alloy |

| Electrical Connection | Shielded Twisted Pair / Cable |

| Power Supply | 18-30 VDC |

| Mounting Type | Threaded or Flanged |

| Accuracy | ±1% of full scale |

| Resolution | 1 µm |

| Dimensions | 91.4 x 144.8 mm |

| Weight | 1.44 kg |

| Compliance | ISO 10816, API 670 |

Product Applications

-

Monitoring critical rotating equipment such as turbines, compressors, and pumps.

-

Providing real-time vibration and shaft displacement data for condition monitoring systems.

-

Enabling early detection of imbalance, misalignment, or bearing wear.

-

Integration with machinery protection systems (MPS) for automated shutdown in case of abnormal operation.

-

Use in power generation, oil and gas, petrochemical, and heavy manufacturing industries.

Product Advantages

-

High Accuracy and Reliability: Ensures precise displacement and vibration measurements under extreme conditions.

-

Robust Design: Resistant to vibration, shock, temperature fluctuations, and harsh industrial environments.

-

Versatile Output Options: Supports differential voltage or 4-20 mA outputs compatible with most monitoring systems.

-

Ease of Installation: Threaded or flanged mounting options allow flexible integration.

-

Compliance with Industry Standards: Meets ISO 10816 and API 670 for machinery monitoring and protection.

-

Early Fault Detection: Helps prevent unplanned downtime and reduces maintenance costs by providing real-time data.

FAQ

Q1: What types of machinery can the PROXPAC XL sensor monitor?

A1: It is suitable for turbines, compressors, pumps, and other rotating equipment in industrial settings.

Q2: How does the sensor output signal work?

A2: The sensor can provide a differential voltage or 4-20 mA output depending on the configuration and connected system.

Q3: What is the typical measurement range?

A3: The standard range is ±25.4 mm, but it can vary based on probe type and application requirements.

Q4: Can it operate in extreme temperatures?

A4: Yes, it operates reliably between -40°C and 120°C.

Q5: Is it compatible with Bently Nevada monitoring systems?

A5: Yes, it is fully compatible with the 3500/46M, 3300 XL, and other Bently Nevada monitoring systems.

Q6: What is the frequency response of the sensor?

A6: It supports a frequency response from DC up to 25 kHz.

Q7: How precise is the sensor?

A7: It offers ±1% full-scale accuracy with a resolution of 1 µm.

Q8: What kind of electrical connection does it require?

A8: It uses a shielded twisted pair or cable for signal transmission.

Q9: Is the sensor suitable for compliance with API 670?

A9: Yes, it is designed to meet API 670 standards for machinery protection.

Q10: Can the sensor detect both displacement and vibration?

A10: Yes, it provides real-time data for shaft displacement and vibration monitoring.

Bently Nevada 330881-28-00-164-07-02 PROXPAC XL Proximity Sensors

Manufacturer:Bently Nevada

Product Number:330881-28-00-164-07-02

Product Type:PROXPAC XL Proximity Sensors

Origin:USA

Dimensions:91.4 x 144.8 mm

Weight :1.44 kg

Views:3

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330881-28-00-164-07-02 PROXPAC XL Proximity Sensor is a high-performance sensor designed for precision monitoring of rotating machinery. It provides reliable vibration and position measurement in demanding industrial environments. The PROXPAC XL series is widely used in critical machinery applications, offering accurate shaft displacement readings and early detection of mechanical issues. This sensor supports robust data acquisition and is engineered to meet the stringent requirements of process and power generation industries.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330881-28-00-164-07-02 |

| Sensor Type | Proximity / Eddy-Current |

| Measurement Range | ±25.4 mm (typical, depending on probe type) |

| Frequency Response | DC to 25 kHz |

| Output Signal | Differential Voltage or 4-20 mA (depending on configuration) |

| Operating Temperature | -40°C to 120°C |

| Housing Material | Stainless Steel / Alloy |

| Electrical Connection | Shielded Twisted Pair / Cable |

| Power Supply | 18-30 VDC |

| Mounting Type | Threaded or Flanged |

| Accuracy | ±1% of full scale |

| Resolution | 1 µm |

| Dimensions | 91.4 x 144.8 mm |

| Weight | 1.44 kg |

| Compliance | ISO 10816, API 670 |

Product Applications

-

Monitoring critical rotating equipment such as turbines, compressors, and pumps.

-

Providing real-time vibration and shaft displacement data for condition monitoring systems.

-

Enabling early detection of imbalance, misalignment, or bearing wear.

-

Integration with machinery protection systems (MPS) for automated shutdown in case of abnormal operation.

-

Use in power generation, oil and gas, petrochemical, and heavy manufacturing industries.

Product Advantages

-

High Accuracy and Reliability: Ensures precise displacement and vibration measurements under extreme conditions.

-

Robust Design: Resistant to vibration, shock, temperature fluctuations, and harsh industrial environments.

-

Versatile Output Options: Supports differential voltage or 4-20 mA outputs compatible with most monitoring systems.

-

Ease of Installation: Threaded or flanged mounting options allow flexible integration.

-

Compliance with Industry Standards: Meets ISO 10816 and API 670 for machinery monitoring and protection.

-

Early Fault Detection: Helps prevent unplanned downtime and reduces maintenance costs by providing real-time data.

FAQ

Q1: What types of machinery can the PROXPAC XL sensor monitor?

A1: It is suitable for turbines, compressors, pumps, and other rotating equipment in industrial settings.

Q2: How does the sensor output signal work?

A2: The sensor can provide a differential voltage or 4-20 mA output depending on the configuration and connected system.

Q3: What is the typical measurement range?

A3: The standard range is ±25.4 mm, but it can vary based on probe type and application requirements.

Q4: Can it operate in extreme temperatures?

A4: Yes, it operates reliably between -40°C and 120°C.

Q5: Is it compatible with Bently Nevada monitoring systems?

A5: Yes, it is fully compatible with the 3500/46M, 3300 XL, and other Bently Nevada monitoring systems.

Q6: What is the frequency response of the sensor?

A6: It supports a frequency response from DC up to 25 kHz.

Q7: How precise is the sensor?

A7: It offers ±1% full-scale accuracy with a resolution of 1 µm.

Q8: What kind of electrical connection does it require?

A8: It uses a shielded twisted pair or cable for signal transmission.

Q9: Is the sensor suitable for compliance with API 670?

A9: Yes, it is designed to meet API 670 standards for machinery protection.

Q10: Can the sensor detect both displacement and vibration?

A10: Yes, it provides real-time data for shaft displacement and vibration monitoring.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...